Reviving the Revolution: How Fix4Bot.com Masters the Art of Robot Repair – From Whispers of Malfunction to Roars of Resurgence

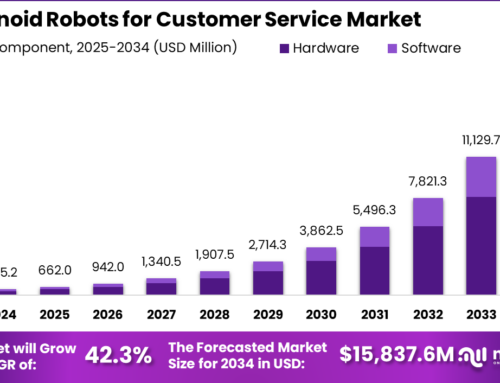

The relentless march of robotics is no longer a futuristic fantasy; it’s the hum of industry, the whir of warehouses, and the quiet assistance in our homes. From complex industrial arms orchestrating intricate manufacturing processes to nimble collaborative robots working shoulder-to-shoulder with humans, and from autonomous mobile robots navigating labyrinthine logistics centers to the increasingly sophisticated service bots entering our daily lives, robots are woven into the fabric of the 21st century. This revolution, however, is predicated on operational excellence. Like any intricate machinery, robots are susceptible to the ravages of time, the unexpected accidents of operation, and the insidious creep of component degradation. When a cog falters in this intricate system, the ripple effect can be substantial – downtime, lost productivity, compromised safety, and escalating costs all threaten to derail the efficiency and progress that robotics promises.

This is where Fix4Bot.com steps onto the stage, not just as a repair service, but as a crucial partner in sustaining the robotic revolution. We aren’t merely technicians wielding screwdrivers; we are diagnosticians unraveling intricate malfunctions, engineers resurrecting sophisticated systems, and guardians ensuring the continued efficacy of your robotic investments. At Fix4Bot.com, we diagnose and repair any damage to any robot, across every conceivable industry and application. This isn’t a boast; it’s a testament to our meticulously cultivated expertise, our unwavering investment in cutting-edge technology, and our profound understanding of the multifaceted world of robotics. We delve deep into the anatomy of robotic failure, wielding a comprehensive arsenal of diagnostic tools and repair methodologies, ensuring that your robots return to optimal functionality, often exceeding their original performance benchmarks.

Let’s embark on an in-depth exploration of how Fix4Bot.com achieves this unparalleled level of robotic restoration, dissecting the intricate processes, advanced technologies, and expert techniques that underpin our promise to revive the revolution, one robot at a time.

The Art of Robotic Diagnosis: Unveiling the Root of the Anomaly

Before a single wrench is turned or a solder gun ignited, the crucial first step in the Fix4Bot.com repair process is meticulous diagnosis. A robot, even seemingly simple ones, is a symphony of interconnected systems – mechanical, electrical, electronic, software, and often even pneumatic or hydraulic. A malfunction in one area can manifest symptoms in another, making accurate diagnosis paramount. We don’t just treat symptoms; we hunt for the root cause, ensuring a robust and lasting repair.

Our diagnostic prowess is built on a multi-layered approach, combining human expertise with the power of advanced technology:

1. Sensor Data Analysis – The Whispers of the Machine:

Modern robots are awash in sensors – encoders tracking joint angles, force sensors detecting collisions, vision systems perceiving the environment, temperature sensors monitoring critical components, and current sensors gauging electrical load. These sensors are the robot’s nervous system, constantly feeding data to its control system. When something goes wrong, these sensors often tell the tale first.

Fix4Bot.com employs sophisticated data logging and analysis techniques. We can connect directly to the robot’s controller, extracting vast streams of sensor data that might seem like noise to the untrained eye. Our expert technicians, trained in the nuances of robotic sensor interpretation, can then utilize specialized software to analyze this data, looking for anomalies, deviations from baseline performance, and patterns indicative of specific failures.

- Predictive Maintenance Insights: Sensor data isn’t just about reactive diagnosis; it’s also about proactive prediction. By analyzing historical sensor data, we can often identify subtle trends that foreshadow impending component failure. This allows us to offer predictive maintenance services, catching potential problems before they escalate into costly downtime. Imagine detecting a slight increase in motor current over time, indicating bearing wear. Addressing this early can prevent a catastrophic motor failure that halts production.

- Fault Isolation through Data Correlation: Robots often report error codes – cryptic messages hinting at the problem. However, error codes can be misleading or too general. Sensor data analysis, combined with error code interpretation, allows for precise fault isolation. For example, an error code indicating "joint motor overload" paired with sensor data showing excessive current draw in that specific motor pinpoint the issue directly.

2. AI-Powered Diagnostic Systems – The Algorithmic Detective:

The volume and complexity of robotic data can overwhelm even the most experienced technicians. This is where Artificial Intelligence comes into play. Fix4Bot.com leverages proprietary AI-powered diagnostic systems trained on vast datasets of robot performance, failure modes, and repair histories.

- Pattern Recognition and Anomaly Detection: Our AI systems are adept at recognizing subtle patterns in sensor data that might be missed by human analysts. They can establish baseline performance profiles for robots and then flag deviations from these profiles as potential anomalies. This is particularly valuable for detecting intermittent faults that are difficult to capture during manual diagnostics.

- Fault Tree Analysis and Probabilistic Reasoning: AI algorithms can perform complex fault tree analysis, systematically exploring potential failure pathways based on error codes, sensor data, and robot schematics. They can use probabilistic reasoning to narrow down the most likely causes of failure, guiding technicians towards targeted investigations.

- Machine Learning for Continuous Improvement: Crucially, our AI systems are not static. They continuously learn from every diagnostic case, refining their algorithms and improving their accuracy over time. This means Fix4Bot.com’s diagnostic capabilities become more powerful and efficient with each robot we repair.

3. Visual Inspection – The Unseen Clues:

Despite the power of data and algorithms, the human eye remains an invaluable diagnostic tool. Experienced technicians at Fix4Bot.com conduct thorough visual inspections, meticulously examining the robot for physical damage, wear and tear, and obvious signs of malfunction.

- Mechanical Component Examination: We check for broken linkages, worn gears, loose bolts, cracked housings, damaged cables, and signs of excessive lubrication or contamination. Visual inspection can often reveal mechanical failures that are not immediately apparent from sensor data.

- Electrical and Electronic Inspection: We look for burnt components, corroded connectors, frayed wiring, bulging capacitors, and signs of overheating on circuit boards. Visual inspection is crucial for identifying obvious electrical faults.

- End-Effector and Tooling Assessment: The robot’s end-effector, the tool at the business end of the robot arm, often bears the brunt of operational stress. We meticulously inspect grippers, welders, spray nozzles, and other end-effectors for damage, wear, misalignment, and proper calibration.

- Internal Component Scrutiny (where feasible): In some cases, with proper safety procedures and robot deactivation, we can perform internal visual inspections, examining circuit boards, motor windings, encoder disks, and other internal components for signs of damage or degradation.

4. Non-Destructive Testing (NDT) – Peering Beneath the Surface:

For critical components where visual inspection is insufficient, or where internal flaws are suspected, Fix4Bot.com employs a range of Non-Destructive Testing (NDT) techniques. NDT allows us to assess the integrity of materials and components without causing damage, revealing hidden defects that could lead to future failures.

- Ultrasonic Testing: Using high-frequency sound waves, ultrasonic testing can detect internal cracks, voids, and corrosion in metallic components like robot arms, bearings, and weld joints. This is particularly useful for assessing the structural integrity of load-bearing parts.

- Radiographic Testing (X-ray and Gamma Ray): Radiographic testing employs X-rays or gamma rays to penetrate materials and create images of internal structures. This can reveal hidden flaws in castings, welds, and complex assemblies that are inaccessible to other methods.

- Thermal Imaging (Infrared Thermography): Thermal imaging cameras detect infrared radiation, visualizing temperature variations across robot surfaces. This can identify overheating components, electrical hotspots, and areas of excessive friction or wear.

- Dye Penetrant Testing: For surface cracks and flaws, dye penetrant testing uses a colored dye that penetrates surface defects, making them visible under UV light after excess dye is removed. This is effective for detecting surface cracks in welds, castings, and machined components.

- Magnetic Particle Testing: For ferromagnetic materials, magnetic particle testing uses magnetic fields and iron particles to detect surface and near-surface cracks and flaws. This is particularly useful for inspecting robot joints, gears, and structural steel components.

5. Simulation and Emulation – Recreating the Robot’s World:

In cases of complex software glitches, control system malfunctions, or intermittent errors, Fix4Bot.com utilizes sophisticated simulation and emulation technologies. We create virtual replicas of the robot and its operating environment to recreate the conditions under which the fault occurs.

- Robot Operating System (ROS) Emulation: For robots running on ROS or similar open-source platforms, we can create virtual environments that mimic the robot’s software and hardware architecture. This allows us to debug software issues, test code modifications, and isolate control system problems in a safe and controlled virtual space.

- Physics-Based Simulation: Using advanced physics simulation software, we can model the robot’s mechanical behavior, sensor feedback, and interaction with its environment. This is particularly useful for diagnosing kinematic and dynamic problems, such as trajectory planning errors, collision avoidance failures, and instability issues.

- Hardware-in-the-Loop (HIL) Simulation: For complex control system issues, we can employ Hardware-in-the-Loop simulation. This involves connecting the robot’s actual controller hardware to a simulated robot model. This allows us to test and debug the real control system software in a virtual environment, isolating hardware and software faults.

The Spectrum of Robotic Repair: From Minor Tweaks to Major Resurrections

Once the root cause of the robotic ailment is accurately diagnosed, Fix4Bot.com deploys a comprehensive arsenal of repair techniques and technologies, tailored to the specific damage and the robot’s architecture. Our repair capabilities span the entire spectrum, from minor software tweaks and component replacements to major structural repairs and complete system overhauls.

1. Software and Control System Repair – The Digital Doctor:

In the age of sophisticated robotics, software glitches and control system malfunctions are a frequent source of operational issues. Fix4Bot.com possesses deep expertise in robotic software and control systems repair.

- Firmware and Software Reprogramming: We can re-flash corrupted firmware, update outdated software, and reprogram robot controllers to address software bugs, performance issues, and compatibility problems. We work with a wide range of robot controller platforms and programming languages.

- Motion Planning and Pathfinding Optimization: For robots exhibiting jerky movements, inefficient trajectories, or navigation errors, we can optimize motion planning algorithms, recalibrate pathfinding parameters, and fine-tune control loops to ensure smooth, efficient, and accurate movement.

- Vision System Calibration and Repair: Robot vision systems are crucial for many applications. Fix4Bot.com can recalibrate vision sensors, repair damaged cameras, and optimize image processing algorithms to restore accurate object recognition, pose estimation, and environmental perception.

- Safety System Recertification and Repair: Robot safety systems are paramount. We can diagnose and repair safety-related faults, ensuring compliance with safety standards and recertifying safety circuits, light curtains, emergency stops, and other safety features.

- Network and Communication Troubleshooting: Many robots operate within networked environments. We can diagnose and repair network connectivity issues, communication protocol errors, and data transfer problems that can disrupt robot operation.

2. Mechanical Component Repair and Replacement – The Mechanical Maestro:

Mechanical failures are an inevitable part of robot operation, due to wear and tear, accidental collisions, and material fatigue. Fix4Bot.com’s mechanical repair expertise is comprehensive and precise.

- Joint and Actuator Repair: Robot joints and actuators (motors, gears, bearings) are critical for motion. We specialize in repairing or replacing damaged motors, rebuilding gearboxes, replacing worn bearings, and restoring smooth and precise joint movement.

- Structural Component Repair and Fabrication: Robot arms, bases, and frames can suffer structural damage from impacts or overloads. We can repair cracks, bends, and deformations in structural components. In cases of severe damage, we can even fabricate replacement structural parts using advanced machining and welding techniques.

- Cable and Wiring Harness Repair: Robots are intricate networks of cables and wiring. Damaged or frayed cables can lead to intermittent faults and complete system failures. We meticulously repair or replace damaged cables, ensuring robust and reliable electrical connections.

- End-Effector and Tooling Refurbishment: Robot end-effectors and tooling experience significant wear and tear. We offer comprehensive refurbishment services, including cleaning, lubrication, component replacement, and recalibration to restore optimal end-effector performance.

- Precision Alignment and Calibration: After any mechanical repair, precision alignment and calibration are essential for accurate robot operation. Fix4Bot.com utilizes laser trackers, coordinate measuring machines (CMMs), and other metrology tools to ensure precise alignment and calibration of robot joints, axes, and end-effectors.

3. Electrical and Electronic Component Repair – The Electronic Elixir:

Robots are complex electronic systems, and failures in electronic components can be particularly challenging to diagnose and repair. Fix4Bot.com’s electronic repair capabilities are at the leading edge of the industry.

- Circuit Board Repair and Rework: We have expertise in repairing damaged circuit boards, including component-level soldering and replacement, trace repair, and BGA (Ball Grid Array) rework for complex integrated circuits.

- Sensor and Encoder Replacement: Damaged sensors and encoders can cripple robot performance. We stock a wide range of replacement sensors and encoders and can perform precise installation and calibration to restore accurate feedback.

- Power Supply and Drive Repair: Robot power supplies and motor drives are critical for reliable operation. We can diagnose and repair faults in power supplies, motor drives, and servo amplifiers, ensuring stable and efficient power delivery to robot components.

- Connector and Wiring Harness Repair: We meticulously repair or replace damaged connectors, wiring harnesses, and terminal blocks, ensuring robust and reliable electrical connections throughout the robot system.

- Electrostatic Discharge (ESD) Protection and Repair: Robots are sensitive to ESD. Fix4Bot.com employs ESD-safe repair practices and can diagnose and repair ESD-related damage to electronic components.

4. Advanced Repair Technologies – The Future of Robotic Restoration:

Fix4Bot.com is committed to utilizing the most advanced repair technologies to ensure unparalleled quality and efficiency.

- 3D Printing and Additive Manufacturing: For obsolete or hard-to-source components, we leverage 3D printing and additive manufacturing to create custom replacement parts. This allows us to repair robots even when original spare parts are no longer available.

- Laser Welding and Micro-Soldering: For delicate electronic components and intricate mechanical repairs, we employ laser welding and micro-soldering techniques, enabling precise and localized repairs with minimal heat damage.

- Robotic Disassembly and Reassembly: In complex cases, we utilize specialized robotic systems for automated disassembly and reassembly, improving efficiency, precision, and safety during the repair process.

- Augmented Reality (AR) Guided Repair: We are exploring the use of Augmented Reality to guide technicians through complex repair procedures, overlaying digital instructions and schematics onto the real robot, enhancing efficiency and accuracy.

- Data-Driven Repair Optimization: We continuously analyze data from our repair processes to identify trends, optimize repair workflows, and improve our diagnostic and repair techniques, ensuring continuous improvement in our service quality.

Beyond Repair: Preventative Maintenance and Performance Enhancement – The Proactive Partner

Fix4Bot.com isn’t just about fixing broken robots; we are dedicated to ensuring their long-term health and optimal performance. We offer comprehensive preventative maintenance programs designed to minimize downtime, extend robot lifespan, and maximize return on investment.

- Regular Inspections and Diagnostics: Scheduled inspections and diagnostic checks allow us to identify and address potential problems before they escalate into major failures.

- Lubrication and Cleaning: Proper lubrication and cleaning are crucial for preventing wear and tear on mechanical components. We perform thorough lubrication and cleaning services according to manufacturer specifications.

- Component Replacement Based on Predictive Maintenance Data: Using data from our sensor analysis and predictive maintenance systems, we can proactively replace components nearing the end of their service life, preventing unexpected failures.

- Performance Optimization and Upgrades: Beyond repair, Fix4Bot.com can also offer performance optimization services and upgrades, enhancing robot speed, accuracy, and capabilities, ensuring your robots remain at the cutting edge of performance.

Fix4Bot.com: Your Partner in Robotic Resilience

The robotic revolution is transforming industries and reshaping our world. To ensure this revolution continues to thrive, robots must be reliable, efficient, and resilient. Fix4Bot.com stands as the cornerstone of robotic resilience, offering unparalleled diagnostic and repair expertise, cutting-edge technologies, and a commitment to keeping your robots – and your business – running smoothly.

From the subtlest software glitch to the most catastrophic mechanical failure, Fix4Bot.com is equipped to diagnose and repair any damage to any robot. We are more than just a repair service; we are your partners in navigating the complexities of robotics, ensuring that your investments remain productive, efficient, and at the forefront of innovation. Contact Fix4Bot.com today, and let us help you revive the revolution and unleash the full potential of your robotic workforce. Because at Fix4Bot.com, we believe that when robots thrive, so does progress.

Leave A Comment