Beyond the Hype: How Fix4Bot.com Can Safeguard Your Robotics Future – Even After Viral Views

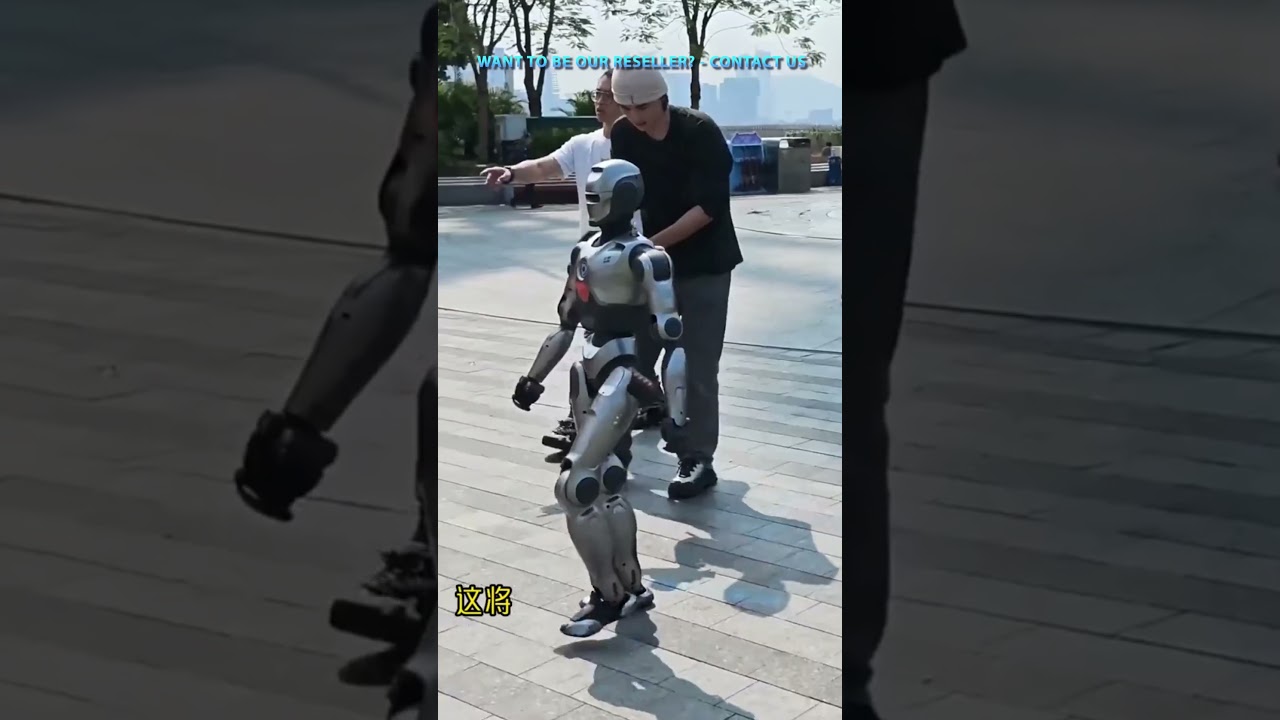

The internet explodes daily with glimpses of tomorrow. Futuristic robotics, AI breakthroughs, and the relentless drive of tech giants like Tesla and Chinese innovators flood our feeds, promising a world transformed. Videos showcasing these marvels, like the recent viral clip highlighting “This is Future Technology on another Level,” rack up views, generate excitement, and inspire awe. But behind the glossy visuals and breathless commentary, a critical question often goes unasked: What happens after the whirring gears stop? What happens when these cutting-edge robots encounter damage, malfunction, or simply require maintenance?

That’s where Fix4Bot.com steps in. We’re not about celebrating the future; we’re about ensuring it stays functional. This article delves into how Fix4Bot.com provides diagnostic and repair solutions for advanced robotics, AI-powered devices, and technologies mirroring those showcased in viral videos like the one featuring Unitree robots and Elon Musk’s visions. We’ll explore the specific challenges these advanced machines present, and how our platform addresses them, moving beyond the fleeting excitement of ‘next-generation’ innovation to the practical realities of maintaining it.

The Fragility of Future Tech: Why High-Profile Robotics Need Specialized Repair

The video in question – and countless others like it – showcase impressive feats of engineering. Unitree’s agile humanoid robots, powered by advanced AI and intricate mechanical systems, are captivating. Tesla’s ongoing innovations, pushing the boundaries of automation and electric vehicle technology, are equally compelling. However, these advancements come with inherent complexities that translate into heightened vulnerability.

Here’s a breakdown of the factors making advanced robotics particularly susceptible to damage and demanding specialized repair:

- Complex Component Integration: Modern robots aren’t built from simple, interchangeable parts. They integrate advanced sensors (LiDAR, cameras, ultrasonic), sophisticated actuators (servo motors, pneumatic systems), powerful embedded processors, and intricate software controls. Damage to any single component can cascade into broader system failure.

- Precision Engineering & Delicate Materials: The performance gains of these robots rely on extremely precise manufacturing and often utilize exotic materials like carbon fiber composites, advanced polymers, and specialized alloys. These are often difficult, if not impossible, for standard repair technicians to handle effectively.

- Proprietary Technology & Software Dependence: Many robots, especially those coming from companies like Tesla and emerging Chinese tech firms, utilize proprietary hardware and software. Simply replacing a broken part isn’t enough; the new component must be integrated and calibrated within a complex software ecosystem.

- AI and Machine Learning Integration: The "intelligence" of these robots is baked into their algorithms. Damage to the processing unit or sensor array can corrupt AI models, leading to unpredictable and potentially dangerous behavior. Repair requires not just hardware replacement, but potentially AI retraining and recalibration.

- High-Stress Operational Environments: The demonstration videos often show robots performing impressive feats – navigating challenging terrain, lifting heavy objects, or operating in industrial settings. These operational stresses can accelerate wear and tear and increase the risk of mechanical failures.

- Limited After-Sales Support: While large companies like Tesla provide some support, smaller robotics firms, especially those emerging from the rapidly evolving Chinese tech sector, can offer limited after-sales support. This leaves owners and operators scrambling when issues arise.

Fix4Bot.com: Your Partner in Extended Robotics Lifespan

Fix4Bot.com isn’t just a repair service; it’s a comprehensive platform built to address the unique challenges of maintaining advanced robotics. We offer a three-pronged approach: Diagnosis, Repair Solutions, and Preventative Maintenance Guidance.

1. Advanced Diagnostic Capabilities:

- Remote Diagnostics: Our secure platform allows technicians to remotely access diagnostic data from your robot, using built-in data logging and communication protocols. This is crucial for initial assessment and trouble-shooting when physical access isn’t possible. We support standard protocols like ROS (Robot Operating System) allowing for deep dives into internal robot telemetry.

- AI-Powered Anomaly Detection: We leverage AI to analyze robot performance data and identify anomalies that may indicate impending failures. This goes beyond simple error code readings, predicting potential problems before they occur.

- Component-Level Fault Isolation: Using a combination of diagnostic tools, specialized software, and expert knowledge, we can pinpoint the specific component responsible for a detected issue. This minimizes unnecessary part replacements and lowers repair costs.

- Bill of Materials (BOM) Verification and Tracking: We maintain a comprehensive database of robotic components, enabling us to accurately identify and source replacement parts, even for obscure models.

2. Targeted Repair Solutions:

- Certified Robotics Technicians: Fix4Bot.com boasts a network of highly skilled and certified technicians with extensive experience in robotics and AI. They are trained to work with a wide range of platforms, including those from Tesla, Unitree, and other leading manufacturers. Specializations include:

- Mechanical Engineering: Repairing and replacing damaged structural components, actuators, and transmissions.

- Electrical Engineering: Troubleshooting and repairing power systems, motor controllers, and sensor circuitry.

- Software Engineering: Debugging and correcting software defects, recalibrating sensors, and retraining AI models.

- AI/ML Specialists: Addressing issues related to AI model degradation, sensor fusion errors, and autonomous navigation problems.

- On-Site and Remote Repair Options: We offer both on-site repair services for complex issues that require physical intervention and remote repair solutions for software-related problems and simpler hardware replacements.

- 3D Printing & Custom Fabrication: For unique or obsolete components, our in-house 3D printing and fabrication capabilities allow us to create custom replacements, mitigating downtime and reducing costs.

- Refurbishment and Upgrade Services: Beyond simple repairs, we offer refurbishment programs to extend the life of your robot and upgrade its capabilities with the latest software and hardware.

3. Preventative Maintenance Strategies:

- Customized Maintenance Schedules: We don’t believe in one-size-fits-all maintenance. Our specialists work with you to develop personalized maintenance schedules based on your robot’s specific usage patterns and environmental conditions.

- Predictive Maintenance Alerts: Leveraging our AI-powered diagnostic capabilities, we provide proactive alerts when we detect signs of potential failures, allowing you to schedule maintenance before a breakdown occurs.

- Knowledge Base & DIY Repair Guides: Our online knowledge base provides a wealth of information on robotics maintenance, including detailed repair guides, troubleshooting tips, and best practices. We aim to empower even non-experts to perform basic maintenance tasks.

- Remote Software Updates & Calibration: We provide remote software updates and calibration services to ensure your robot’s performance remains optimal.

Addressing Specific Challenges from the "Future Tech" Landscape:

Let’s consider how Fix4Bot.com addresses some of the specific challenges presented by the types of robots showcased in the viral video:

- Unitree Humanoid Robots: These robots are complex, featuring numerous servo motors, delicate sensors, and advanced AI control systems. A common failure point is the servo motors, which can wear out or become damaged due to impacts. We offer specialized servo motor repair and replacement services, along with assistance in re-tuning the robot’s gait and balance algorithms.

- Elon Musk & Tesla Robotics: Tesla’s robotics initiatives, including their work on humanoid robots and automated manufacturing systems, demand a high degree of precision and reliability. Repairing these robots often requires specialized diagnostic tools and access to proprietary software. Fix4Bot.com’s certified technicians have experience working with Tesla systems and can navigate these challenges.

- Chinese Tech Innovations: The rapid pace of innovation in Chinese robotics means new models and technologies are constantly emerging. We actively cultivate relationships with Chinese manufacturers to stay abreast of the latest developments and ensure our technicians are trained on their products. Our multi-lingual support team can also assist with communication and sourcing parts.

- AI-Powered Systems: Ensuring the integrity and performance of the AI that powers these robots is paramount. We specialize in AI model diagnostics and retraining, using techniques like federated learning to preserve user data while optimizing algorithms.

Beyond Repair – Building a Sustainable Robotics Ecosystem

Fix4Bot.com’s vision extends beyond simply fixing broken robots. We are committed to building a sustainable robotics ecosystem that promotes responsible innovation and minimizes e-waste. This includes:

- Component Recovery & Recycling: We prioritize the recovery and recycling of usable components from damaged robots, reducing environmental impact and lowering repair costs.

- Promoting Open-Source Repairability: We actively support initiatives to promote open-source robotics hardware and software designs, making robots easier to repair and maintain.

- Advocating for Responsible Robotics Manufacturing: We engage with manufacturers to advocate for more durable designs, readily available spare parts, and transparent repair documentation.

The mesmerizing videos showcasing the future of robotics are undeniable proof of incredible progress. However, realizing that future requires more than just innovation – it demands a robust infrastructure for maintenance, repair, and sustainable operation. Fix4Bot.com is dedicated to providing that infrastructure, ensuring that the promise of advanced robotics isn’t short-lived, but rather a lasting reality. Don’t let the inevitable challenges of maintaining these sophisticated machines dim your enthusiasm. With Fix4Bot.com, you can confidently embrace the future, knowing that we’re here to keep it running.

Entre esos dos robots que se saludaron,uno de ellos aún guarda un poco de rencor por algo…😂😂😂

Bet the Twitter guy is jealous 🤣🤣😂🤣🤣😂🤣😂🤣

덤블링 멋져 로봇

Left it hangin!

Elon mini me.

It made a fwd flip w/o the head on.

중국 무섭게 치고 올라오네

😮😮😮😮

bayangkan robot itu di lengkapi kecerdasan ai,dan berbuat kejahatan,

gambaran terminator bener bener nyata

這個啊,給紅衛兵就死定了他對付人民

🎉🎉🎉

Boston dynamics robots or even better 🤗

I wonder whose idea it was to give it a heart?

流石日本メーカーのロボットだね

メイドインジャパンは、ここまで進化したのかよ