The Silent Guardians: Diagnosing and Repairing RoMeLa Humanoid Robots – A Fix4Bot.com Guide

For two decades, the Robotics & Mechanisms Laboratory (RoMeLa) at Korea Advanced Institute of Science and Technology (KAIST) has been at the forefront of humanoid robotics, consistently pushing the boundaries of what’s possible in bipedal locomotion, manipulation, and autonomous behavior. From the pioneering HUBO series to the more advanced and agile robots currently in development, RoMeLa’s creations have captivated the world and fuelled advancements across numerous fields. But even the most sophisticated robots are susceptible to damage, wear and tear, and unforeseen malfunctions. This article, brought to you by Fix4Bot.com, delves into the complexities of diagnosing and repairing these intricate machines, offering a comprehensive guide for engineers, researchers, and maintenance personnel working with RoMeLa humanoid robots. We’ll explore common failure points, essential diagnostic tools, and the tailored repair solutions Fix4Bot.com provides to ensure your RoMeLa robot remains operational and contributing to groundbreaking research.

The RoMeLa Legacy: A Brief Overview

Before diving into repair protocols, understanding the evolution of RoMeLa’s humanoid robots is crucial. The journey began in 2004 with the first HUBO (Humanoid Robot Built On a robust and adaptable design) platform. This initial model laid the groundwork for subsequent iterations – HUBO II, HUBO+, and beyond – each boasting improved capabilities in balancing, walking, and object manipulation. These developments heavily emphasized robust mechanical design and sophisticated control algorithms. Significant advancements were also realized in the integration of sensors—force/torque sensors, vision systems, and inertial measurement units (IMUs)—which have become fundamental for reactive balancing and environmental interaction.

The current generation of RoMeLa robots represents a further leap in technology, incorporating lighter materials, higher-performance actuators, and AI-driven learning capabilities. The commitment to continued innovation is evident in the anticipation surrounding the 2025 release, promising even greater levels of autonomy and dexterity. However, this complexity also translates to an increased potential for diverse failure modes.

Common Failure Points in RoMeLa Humanoid Robots

RoMeLa humanoid robots, like any complex electromechanical system, are prone to specific points of failure. Understanding these potential weaknesses is the first step in effective diagnosis and repair:

- Actuators (Motors, Gearboxes, Harmonic Drives): The actuators are the "muscles" of the robot, and arguably the most common source of trouble. Excessive stress, unexpected impacts, or even prolonged operation can lead to motor burnout, gearbox wear, and damage to harmonic drive units (often employed for their high torque density and precision). Stalling, unusual noises (grinding, clicking), and reduced power are key indicators.

- Sensors (Force/Torque, IMUs, Vision Systems, Encoders): Sensors provide crucial feedback for control, and their failure can compromise the robot’s stability, navigation, and manipulation abilities. Force/torque sensor drift, IMU inaccuracies, camera lens obstructions, and encoder errors are frequent problems.

- Mechanical Structure (Frame, Joints, Cables): Repeated stress and impacts can lead to cracks, bends, and fractures in the robot’s frame. Joints can experience wear, particularly in areas with high contact pressure. Cables, used for transmitting power and data, are also susceptible to fraying and breakage.

- Power Electronics (Motor Controllers, Batteries, Power Supplies): Power components are essential for robot operation. Issues within the motor controllers, battery degradation, or power supply failures can result in erratic behavior or complete shutdown.

- Computational Hardware (Embedded Systems, Processors): While less common, software glitches, overheating, or hardware failures within the robot’s embedded systems and processors can disrupt operation.

- Wiring and Connectors: Constant movement and stress on wiring harnesses can lead to loose connections, shorts, and signal degradation. Inspect connectors regularly for corrosion and damage.

- Foot and Leg Interactions: The feet and legs, constantly in contact with the environment, experience significant wear and tear. This includes degradation of foot pads, wear on ankle joints, and damage to lower leg structures.

Diagnostic Techniques: Pinpointing the Problem

Effective repair begins with meticulous diagnosis. Fix4Bot.com emphasizes a systematic approach:

- Visual Inspection: Begin with a thorough visual inspection of the entire robot. Look for cracks, loose fasteners, damaged wiring, and any signs of physical stress. Pay close attention to areas with frequent movement or potential impact points.

- Performance Testing: Conduct standardized performance tests to assess the robot’s capabilities. Check walking speed, balance stability, object manipulation accuracy, and sensor readings under controlled conditions. Deviations from expected performance indicate potential issues.

- Software Diagnostics: Utilize the robot’s diagnostic software provided by RoMeLa. These tools often provide real-time sensor data, motor current readings, and error logs that can pinpoint specific failures.

- Sensor Calibration: Regularly calibrate sensors to ensure accuracy. Utilize provided calibration routines or specialized calibration equipment.

- Actuator Testing: Individually test each actuator’s performance using a dynamometer or by observing its response to commanded movements. Look for anomalies in torque output, speed, and responsiveness.

- Thermal Imaging: Employ thermal imaging to identify components that are overheating, which can indicate a failing motor controller or excessive friction within a gearbox.

- Oscilloscope Analysis: Using an oscilloscope, monitor motor currents and voltages to identify unusual waveforms that may signify motor winding faults or control signal issues.

- Multimeter Testing: Use a multimeter to check for continuity and resistance in wiring harnesses, connectors, and power supply lines.

Fix4Bot.com’s Repair Solutions: Tailored to RoMeLa Robotics

Fix4Bot.com specializes in providing comprehensive repair and maintenance solutions for advanced robotics, including a dedicated support network for RoMeLa humanoid robots. Our services are designed to minimize downtime and maximize the lifespan of your valuable research equipment:

- Component Procurement: We maintain a comprehensive inventory of replacement parts for RoMeLa robots, including actuators, sensors, motor controllers, batteries, and structural components. Our sourcing network extends globally, allowing us to acquire even hard-to-find parts quickly. We understand the intricacies of RoMeLa’s components and ensure compatibility with your specific robot model and revision.

- Actuator Repair and Refurbishment: Our expert technicians can diagnose and repair damaged actuators, including motor winding repairs, gearbox rebuilds, and harmonic drive replacements. We offer both on-site and off-site refurbishment services. Our processes include thorough testing and calibration to ensure optimal performance after repair.

- Sensor Replacement and Calibration: We provide accurate sensor replacements, coupled with professional calibration services, ensuring accurate and reliable data.

- Mechanical Repair and Fabrication: Our team possesses the skills and equipment to repair the robot’s mechanical structure, including welding, machining, and 3D printing. We can fabricate custom replacement parts or modify existing components to improve performance or address design flaws.

- Software Troubleshooting and Updates: We can assist with software troubleshooting and apply firmware updates to optimize robot performance and address known bugs. We work in accordance with RoMeLa’s provided software development kits (SDKs).

- Preventative Maintenance Programs: We offer customized preventative maintenance programs to proactively identify and address potential issues before they lead to costly breakdowns. These programs include regular inspections, sensor calibrations, lubrication, and component replacements based on usage patterns.

- Remote Diagnostics & Support: Leveraging secure remote access tools, our engineers can provide real-time diagnostics and guidance to assist on-site technicians in troubleshooting and resolving issues.

- Expert Consultation: Need advice on a specific repair challenge or seeking guidance on optimizing robot performance? Our team of robotics experts is available for consultation and technical support.

The 2025 Robot & Beyond: Future-Proofing Your Investment

RoMeLa’s anticipated 2025 release signals the next evolution in humanoid robotics. While details remain scarce, Fix4Bot.com is proactively preparing for this advancement by:

- Developing a Knowledge Base: We are actively gathering information about the expected architecture and components of the new robot to prepare diagnostic and repair resources.

- Extending Component Sourcing: We’re expanding our sourcing network to include potential suppliers of components for the new platform.

- Training Our Technicians: Our technicians are undergoing advanced training to ensure they are equipped to handle the complexities of the next-generation RoMeLa robot.

- Developing Specialized Repair Tools: Recognizing the potential for new failure modes, we are designing and developing specialized repair tools tailored to the anticipated robot design.

Conclusion

RoMeLa’s humanoid robots represent a significant investment in advanced robotics research. Protecting this investment requires a proactive approach to maintenance and a reliable partner for repair services. Fix4Bot.com offers the expertise, resources, and commitment to keep your RoMeLa robots operational and contributing to breakthroughs in robotics and related fields. From expert diagnostics to comprehensive repair solutions, we are your trusted partner in ensuring the silent guardians of RoMeLa continue to inspire and innovate for years to come. Contact us today to discuss your specific needs and learn how Fix4Bot.com can help you maximize the lifespan and performance of your RoMeLa humanoid robot.

[Fix4Bot.com Website Link/Contact Information Here]

Год за годом учатся ходить,учатся видеть,это поразительно и удивительно 🔥👍

Господа создатели,вы не делайте из этого всего клоунаду,и почаще мозги проветривайте,это полезно 🤕

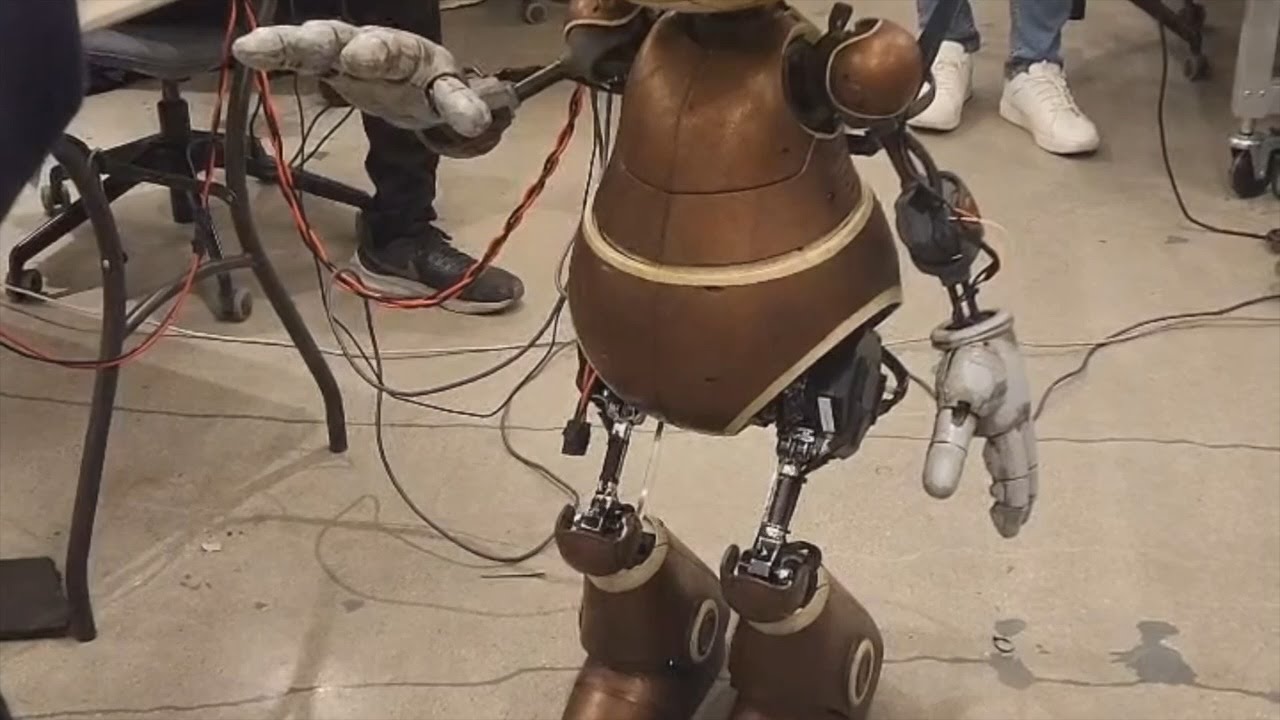

In the end, it looks like an animatronic from FNAFA, I don't want to offend the authors

A cartoon robot?

9:03 – Robô da Thumb

Assinat:

Deus/Jesus seja SEMPRE LOUVADO e DIGNO de Toda Honra e Glória pq é o Autor da nossa Salvação pra Vida Eterna no Reino de Deus!!!

Deus/Jesus é LIBERTAÇÃO!!!

🙏🏻🙌🏻

Forte Abraço

e Tudo de Bom com Jesus!!!

Interesting! But why is there a gap between 2017 and 2022? (covid?)

Electric state was such a good film im glad this robot is being made

0:43 you can tell by their scream that it took them many, MANY hours of work.

Robots are just so cool :D

My preference (-) idiot and stuped 😂😅😊

Robot at the end reminds me of Clank :D

1:26 🤣🤣🤣

Cosmo?

My boy Cosmo

A evolução da robótica depende em parte da criação de novos componentes e materiais. Desafios como baterias mais compactas e com maior eficiência, sensores e acionadores mais sofisticados e em alguma medida pensar soluções diferentes da maioria.

why do they keep making robots look , act , talk , walk like humans?

Did they use your CosmoBoy robot for Electric State the movie? The puppet was real?

Why are little robots playing soccer so cute?

Medabots😮

I’m surprised no one’s using the last one to make a steamboat Willie animatronic for fun

sait trop cool

last robot looks like it's from atomic heart

Yoooo that last robot is the robot they used in The electric state

7:07 Cosmo-bot from Electric State??

Omg is it him the movie 😊

Do they get a bit quirky at night?

O my Boy. You are so beautiful. I look forward to them giving you a body and a voice.

Nice work in the electric state model sadly in the movie it looks all cgi so its kinda useless

I like the "no shoes indoors" crowd. my people!