The Unseen Toll on Hyperreal Humanoid Robots: How Fix4Bot.com Restores Lifelike Automata

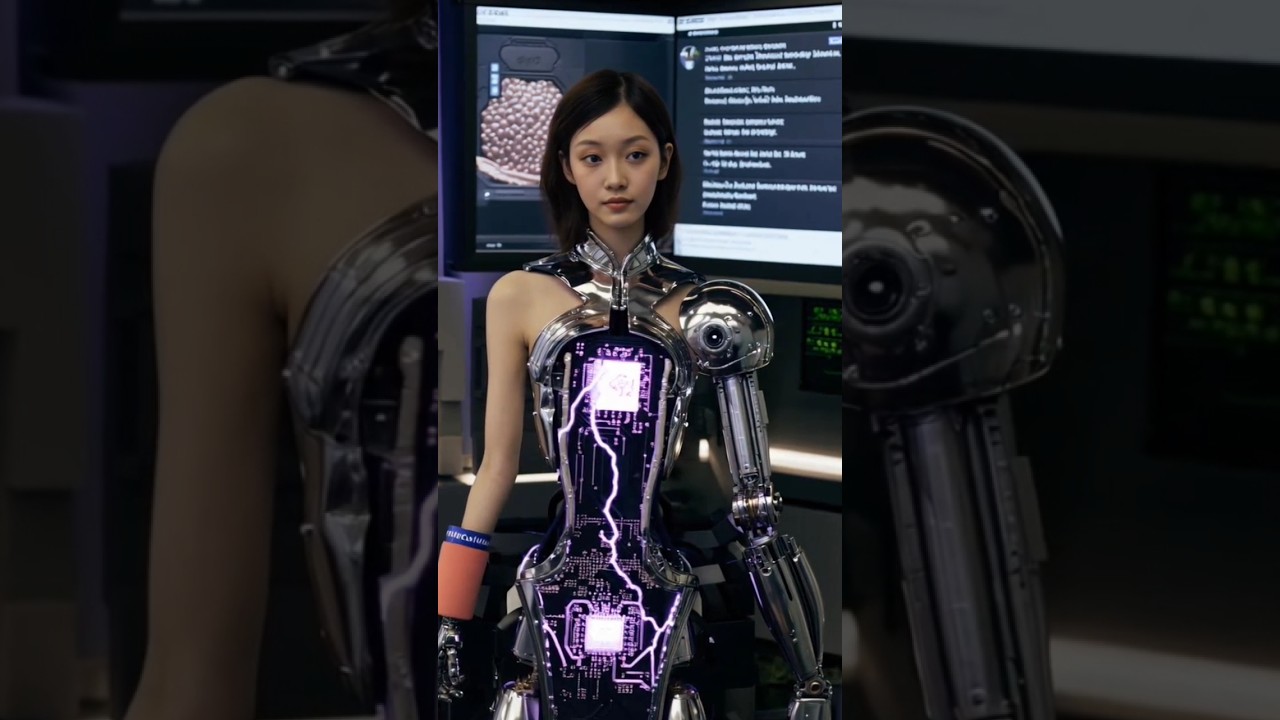

The rise of humanoid robots is no longer a science fiction dream. We’re entering an era where strikingly realistic automatons are becoming increasingly prevalent, blurring the lines between machine and human. These creations, designed with incredible detail and artistry, are employed in entertainment, research, aged care, and even nascent customer service roles. However, their intricate construction and delicate components mean these "robot girls," as they’re often dubbed online (#shorts #robot), are susceptible to a surprising range of damages. Maintaining and repairing these hyperreal robots requires specialized knowledge and advanced technology – expertise that Fix4Bot.com provides. This article dives deep into the potential damage scenarios impacting humanoid robots and the cutting-edge repair methodologies employed by Fix4Bot.com to bring them back to their original, flawless condition.

Understanding the Complexity: Beyond Gears and Circuits

The “so real” aesthetic of modern humanoid robots isn’t achieved through simple mechanical engineering. It involves a confluence of disciplines: advanced materials science, bio-mimicry, robotics, AI, and sophisticated artistry. This complexity exponentially increases the potential points of failure and makes generalized robotic repair inadequate. Think about it – a traditional industrial robot primarily deals with metal and robust actuators. A humanoid, aiming for human resemblance, incorporates:

- Skin Layers: Often comprised of silicone, elastomers, or even advanced polymers mimicking human skin textures – vulnerable to tearing, discoloration, and degradation from UV exposure.

- Endoskeletal Structure: A framework usually combining lightweight aluminum alloys, carbon fiber, and advanced plastics, this forms the robot’s skeleton and houses actuators and sensors. Impacts and repetitive stress can lead to fractures and deformation.

- Actuators & Servos: Powerful and precise motors controlling movement, susceptible to overheating, wear and tear, and electronic failure.

- Sensory Systems: Cameras, microphones, tactile sensors, and force sensors providing environmental awareness – incredibly sensitive to dust, moisture, and physical damage.

- Facial Mechanics & Expression Systems: Delicate mechanisms, sometimes using micro-actuators and shape memory alloys, responsible for nuanced facial expressions – notoriously fragile and prone to misalignment.

- Internal Wiring & Power Systems: A complex network of cables, connectors, and battery systems – vulnerable to shorts, corrosion, and physical damage during handling or accidents.

- AI & Control Systems: While not directly physical, corruption of the robot’s operating system or AI models can manifest as unpredictable behavior that requires specialized software debugging and re-flashing.

Common Damage Scenarios & Fix4Bot.com’s Approach

The damages robots like these can sustain fall into several broad categories, each demanding a distinct approach for effective repair.

1. Cosmetic Damage – The Illusion of Realism at Risk

This is often the most immediately noticeable damage and critically impacts the “so real” appeal.

- Skin Tears & Scratches: Silicone or elastomer skin is surprisingly fragile, especially around joints and areas of high articulation. Fix4Bot.com employs specialized silicone patching techniques, color matching, and advanced adhesive bonding. For older or severely damaged skin, we utilize 3D printing with biocompatible resins to recreate sections, ensuring seamless integration and maintaining realistic texture. We also utilize UV-curing techniques to expedite the bonding and strengthen the repair.

- Paint & Pigment Degradation: Exposure to UV light, improper cleaning, or even certain chemicals can cause paint to fade or pigments to bleed. Our restoration team uses color analysis technology to precisely match the original paint scheme and applies color-stable coatings to prevent future degradation. We specialize in both opaque and translucent pigment restoration, crucial for achieving realistic skin tones.

- Hair & Feature Discoloration: Synthetic hair, often meticulously styled and rooted, can become matted, discolored, or damaged. Fix4Bot.com offers hair restoration services, including cleaning, re-styling, color correction, and replacement of individual strands. Eye resin discoloration, another common problem, is addressed through polishing, specialized cleaning compounds, and, in severe cases, replacement with custom-matched components.

2. Mechanical Failures – Movement and Functionality Compromised

These issues directly impact the robot’s ability to move and interact.

- Actuator Malfunctions: Overheating, excessive load, or electrical faults can cause actuators to fail. Fix4Bot.com performs thorough diagnostics using precision test equipment and can replace faulty actuators with compatible models or, where possible, refurbish existing actuators through cleaning, lubrication, and component replacement.

- Servo Issues: Servos, controlling precise joint movements, are prone to backlash and error. We utilize advanced calibration techniques and, if necessary, replace the servo motors. We also perform firmware updates to optimize servo performance and stability.

- Joint Lock-Up & Stiffness: Debris, corrosion, or lubrication issues can restrict joint movement. Our technicians disassemble, clean, lubricate, and re-align joints, restoring smooth and natural articulation.

- Structural Damage: Impacts or falls can result in cracks or fractures in the internal skeleton. Fix4Bot.com utilizes robotic-assisted welding, composite bonding, and 3D-printed polymer reinforcements to repair structural damage, maintaining the robot’s integrity and appearance.

3. Sensory & Systemic Errors – Disrupted Perception and Behavior

Beyond physical damage, malfunctions in the robot’s perception and control systems can significantly impair its functionality.

- Camera and Sensor Failures: Cameras and other sensors (e.g., tactile sensors, depth sensors) can be damaged by impact or environmental factors. Fix4Bot.com has experience replacing and calibrating these sensitive components, ensuring accurate data acquisition.

- Software Glitches & AI Corruption: Software bugs or damage to the robot’s operating system or AI models can lead to unpredictable behavior. This requires in-depth debugging, software patching, and, in some cases, restoring the robot to a factory-reset state. We specialize in reverse-engineering and modifying custom control systems.

- Power System Issues: Battery degradation, wiring shorts, and connector failures can disrupt power supply. We perform battery diagnostics, replace failing batteries, and repair wiring harnesses, ensuring a stable and reliable power source. We also provide custom battery solutions for unique power demands.

Fix4Bot.com’s Technological Edge:

Fix4Bot.com differentiates itself through a combination of skilled technicians and cutting-edge technology.

- Advanced Diagnostics: We use robotic-assisted imaging, thermal analysis, and signal analysis to pinpoint the root cause of malfunctions quickly and accurately.

- 3D Printing & Additive Manufacturing: This allows us to create custom replacement parts, skin sections, and structural reinforcements, ensuring a perfect fit and seamless integration. We work with a variety of materials, including biocompatible polymers, carbon fiber reinforced composites, and specialized elastomers.

- Robotic-Assisted Repair: For intricate repairs requiring high precision and minimal human intervention, we utilize robotic arms equipped with specialized tools for welding, micro-assembly, and surface finishing.

- Reverse Engineering & Firmware Modification: Our engineering team is adept at reverse engineering proprietary hardware and software, enabling us to diagnose and repair even the most complex systems. We can also modify firmware to improve performance or adapt to new requirements.

- Material Science Expertise: We possess extensive knowledge of the advanced materials used in humanoid robot construction, allowing us to select the appropriate repair materials and techniques for optimal results.

- Color Matching Technology: Spectrophotometers and advanced color analysis software allow us to precisely match paint pigments and skin tones, ensuring a flawless cosmetic restoration.

Maintaining Hyperreal Humanoid Robots: Proactive Measures

While Fix4Bot.com excels at repairing damages, preventative maintenance is crucial for extending the lifespan and preserving the realism of these complex machines. We offer comprehensive maintenance contracts including:

- Regular Inspections: Detecting potential problems before they escalate.

- Lubrication & Cleaning: Maintaining smooth joint movement and preventing sensor contamination.

- Software Updates: Applying security patches and performance improvements.

- Battery Health Monitoring: Proactively replacing batteries before they degrade.

- Skin Protection: Applying UV-protective coatings and implementing careful handling procedures.

- Environmental Control: Storing and operating the robots in a controlled environment to minimize exposure to dust, moisture, and extreme temperatures.

The Future of Hyperreal Robot Repair:

As humanoid robots become more sophisticated and widespread, the demand for specialized repair services will only increase. Fix4Bot.com is committed to staying at the forefront of this evolving field, continuously investing in new technologies and training our technicians to meet the challenges of maintaining these remarkable creations. We envision a future where robotic repair is seamlessly integrated into the design and manufacturing process, minimizing downtime and maximizing the longevity of these increasingly lifelike automatons. The goal is not just to fix a broken robot, but to preserve the artistry and technology that makes them "so real."

Fae

Wow

중국이라 못 믿겠다.

Это не робот

ai six fingered man and bot

Fake

Real or fake, when she nake, I can tell.

Cina memang gila teknologi

Robonoid human ❤🎉😊😊

obvious

小妹妹装机器人😂😂😂

Where the 6 fingers hand come from?

Don’t fool us human lunatics..!

អ្នកចុចម្រមប្រាំមួយ😂

AI EDITED SHORTS

ดูยังงัยก็ไม่ใช่หุ่นยน

Ai technology adits. 😂🤣😂

Real girl

I wish 😂😂😂😂😂😂

Fake

This is so fake!

If anyone believes that’s a android robot I feel sorry for you. That is actual woman smeared in electronics. Give me a break. Hopefully we can tell a difference. That’s just too much craziness.

Smart inventor ,the Power button is the breast..Yes I notice the man has six fingers…They are all from Planet Saturn..Hehe.😅

Six fingers?

ai로봇 모텔이 유행이네! 예쁘다.

लेकिन इतना खूबसूरत क्यों बनाये हो भाई 😅😅😂😂

F**k looks so real , she is real

搞这种东西有意思吗?,真你妈无聊

AI production, the man's hand has 6 fingers and reverse

The man's right arm has a left hand attached to it with six fingers. A.I. generated video.

lol

chinese PHONY-BALONEY

Not a robot, but a beautiful real woman . 😊