The Dawn of the Synthetic Self: Diagnosing and Repairing the Frontier of Humanoid Robotics – A Fix4Bot.com Perspective

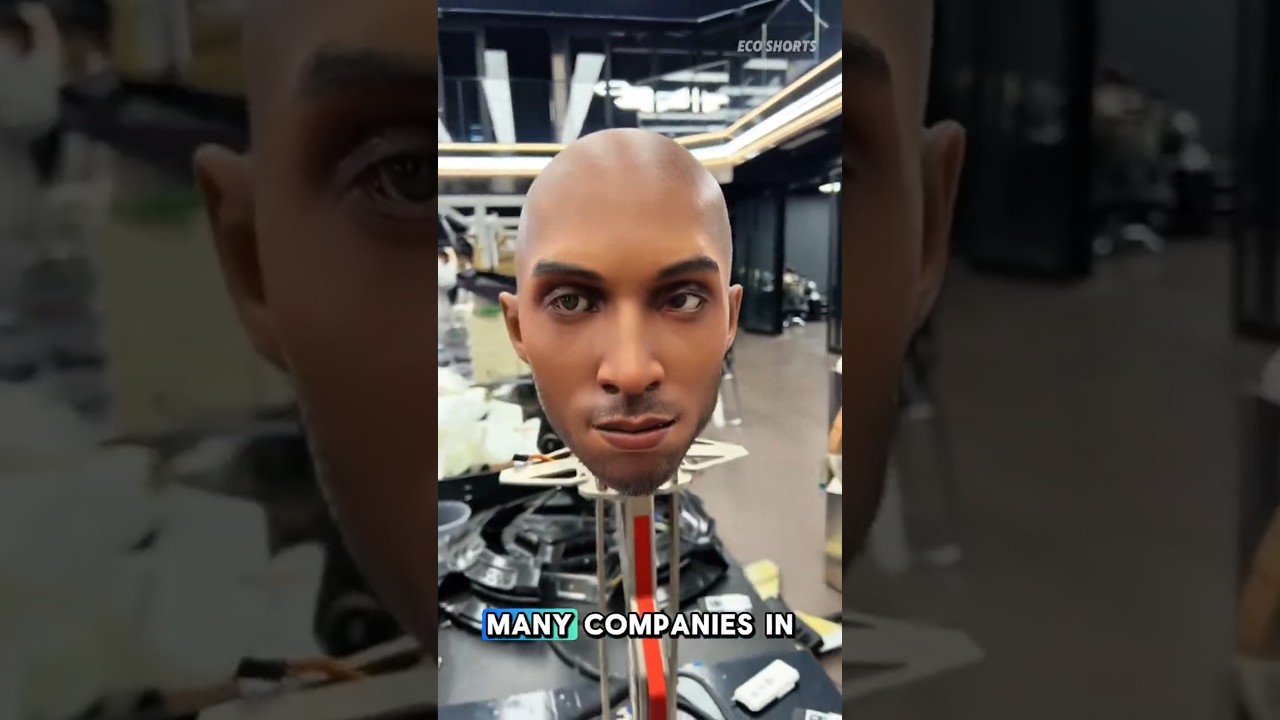

The headlines are unavoidable. Videos are going viral. The world is collectively holding its breath. China’s advancements in humanoid robotics represent a monumental leap—a step closer to machines that not only mimic human appearance but appear to emulate human capabilities, even human emotion. The question echoing across the internet isn’t just “How?” but “What happens next?” Will the line between human and machine blur to the point of indistinguishability?

Here at Fix4Bot.com, we’re accustomed to dealing with the mechanical and electronic intricacies of robotic systems. We repair industrial arms, maintain automated vehicles, and troubleshoot complex drone technologies. But the emergence of convincingly human-like robots pushes the boundaries of our expertise, demanding a new level of diagnostic rigor and innovative repair solutions. This article will delve into the challenges presented by these advanced humanoid robots, the types of damage we anticipate, and how Fix4Bot.com is adapting to provide unparalleled repair and maintenance services for this rapidly evolving sector.

Beyond Appearance: The Complexity of Humanoid Robotics

The visual realism of these new robots is undeniable, but achieving that realism is only the tip of the iceberg. Consider the intricate systems working in concert to create a convincing imitation of a human being:

- Advanced Materials & Actuation: The "skin" itself isn’t simply plastic. It’s a blend of advanced polymers, silicone, and potentially even bio-inspired materials designed to mimic the texture, elasticity, and even temperature of human skin. Internally, these robots rely on intricate actuator systems – electric motors, pneumatic cylinders, and hydraulic components – to reproduce subtle movements, facial expressions, and natural walking gaits.

- Sensory Input & Processing: Humanoid robots need to sense the world around them. This relies on a constellation of sensors: high-resolution cameras for vision, microphones for audio, tactile sensors embedded in the "skin" for touch, and potentially even pressure sensors to mimic proprioception (the sense of body position). Processing this sensory data requires powerful AI algorithms, capable of interpreting complex visual cues, understanding language, and responding appropriately.

- Artificial Intelligence & Machine Learning: The ability to “learn from us” as the initial video suggests hinges on sophisticated AI. These robots utilize machine learning algorithms – often deep neural networks – to analyze data, identify patterns, and adapt their behavior. The complexities of developing and maintaining these algorithms within a humanoid framework represent a significant challenge.

- Power Management & Thermal Regulation: Powering these complex systems, particularly with the high energy demands of servo motors and AI processing, is a major hurdle. Efficient power management and robust thermal regulation are crucial to prevent overheating and system failure.

- Bio-Mimicry & Control Systems: Replicating the nuances of human movement and interaction demands incredibly precise control systems capable of coordinating hundreds, if not thousands, of individual actuators. Bio-mimicry – studying and replicating biological systems – plays a significant role here, using insights from human anatomy and movement to optimize robotic design.

Potential Damage Scenarios: What Can Go Wrong?

Given this complexity, the potential failure points are numerous. While many issues will mirror those encountered in traditional robotics, humanoid robots introduce unique vulnerabilities:

- Skin and Cosmetic Damage: The exterior "skin" is perhaps the most visible and arguably the most fragile point of failure. Tears, abrasions, discoloration, and even separation from the underlying endoskeleton are likely occurrences. These aren’t simply cosmetic – damage to the skin can expose sensitive internal components to the environment.

- Actuator Degradation and Failure: The constant, precise movements required to mimic human behavior place immense stress on actuators. Wear and tear, overheating, and electrical failures are all common concerns. Replacing or repairing actuators within the confined spaces of a humanoid robot – especially those responsible for facial expressions – presents a significant engineering challenge.

- Sensor Malfunctions: Cameras, microphones, and tactile sensors are susceptible to damage from impacts, dust, moisture, and electromagnetic interference. Calibration drift – where sensors begin to provide inaccurate readings – is also a common issue.

- AI and Software Errors: Bugs in the AI code, corrupted data, and conflicts between different software modules can lead to unpredictable behavior and system instability. Debugging these issues requires a deep understanding of both the robotic hardware and the underlying AI algorithms. “Hallucinations” in the AI (generating false information) also represent potential harm scenarios, which is why strict maintenance of the AI library is mandatory.

- Power System Failures: Battery degradation, regulator failures, and wiring issues can lead to power interruptions and system shutdowns. Overheating is a particular risk, potentially damaging sensitive electronic components.

- Structural Damage: Impacts, falls, or even sustained stress during operation can cause damage to the robot’s internal frame and structural components.

- User Interaction Damage: Humanoid robots are designed to interact with humans. This interface intrinsically introduces the possibility of damage; accidental bumps, grabs, or deliberate adversarial actions can lead to a range of problems.

Fix4Bot.com’s Approach to Humanoid Robot Repair

Fix4Bot.com is proactively expanding our capabilities to address the unique challenges of humanoid robot repair. Here’s a breakdown of our planned strategies:

1. Specialized Diagnostic Tools & Techniques:

- Advanced Imaging: We’re investing in non-destructive testing (NDT) technologies such as thermography, ultrasonic testing, and radiographic inspection (X-ray) to identify hidden damage within the robot’s structure and internal components.

- AI-Powered Diagnostic Software: We’re developing bespoke software that integrates with the robot’s control systems to analyze sensor data, identify anomalies, and provide detailed diagnostic reports. This software will learn from historical data to predict potential failures and proactively schedule maintenance.

- Robotic Endoscopy: Specialized cameras mounted on miniature robotic probes allow for visual inspection of hard-to-reach areas within the robot’s body, without requiring extensive disassembly.

- Behavioral Analysis: Beyond purely hardware diagnostics, we’ll focus on analyzing the robot’s behavior for anomalies – unusual movements, speech patterns, or responses. This can help identify subtle software glitches or sensor malfunctions.

2. Targeted Repair Expertise & Resources:

- Materials Science Specialists: Our team will incorporate material scientists familiar with advanced polymers, silicones, and composite materials to address skin repair and structural damage.

- Actuation & Mechatronics Engineers: We’ll expand our team of engineers specializing in actuator technology, servo control, and pneumatic/hydraulic systems. These experts will be trained in diagnosing and repairing sophisticated robotic joints and limb mechanisms.

- AI & Software Debugging Experts: We’ll incorporate software engineers and data scientists skilled in debugging AI algorithms and machine learning models. They’ll work closely with robotics engineers to identify and resolve software-related issues.

- Bio-Mimicry Collaboration: We see immense value in partnerships with bio-mechanics experts. We will provide the support of biomechanics to replicate the motion of human-like movements and functionality.

- Custom Component Fabrication: In cases where replacement parts are unavailable or difficult to obtain, we’ll offer rapid prototyping and 3D printing services to fabricate custom components.

- Modular Design Repair Focus: Promoting manufacturers adopting modular designs fosters ease of maintenance and faster repairs. Our team will offer repair solutions targeted at modular components.

3. Proactive Maintenance Programs:

- Preventative Maintenance Schedules: We’ll develop customized preventative maintenance schedules for each robot, based on its usage patterns and environmental conditions. These schedules will include routine inspections, sensor calibrations, and component replacements.

- Remote Monitoring & Diagnostics: We’ll offer remote monitoring services that allow us to track the robot’s performance, identify potential issues early on, and proactively schedule maintenance.

- Predictive Maintenance using Machine Learning: Leveraging machine learning algorithms to analyze sensor data and predict component failures before they occur. This will minimize downtime and optimize maintenance schedules.

- Training and Support for Owners: We’ll offer training programs for robot owners and operators, focusing on basic maintenance procedures, troubleshooting techniques, and safe operating practices.

The Ethical Considerations & Our Commitment

The rapid advancement of humanoid robotics presents profound ethical challenges. We recognize the potential for these technologies to be misused, and we are committed to providing our services in a responsible and ethical manner. We adhere to strict data privacy protocols, ensuring that all data collected during diagnostics and repair is handled securely and confidentially. We also prioritize transparency in our repair processes, providing clients with clear explanations of the issues identified and the solutions implemented. Our commitment is to support the responsible development and deployment of humanoid robots, ensuring that these powerful technologies are used for the benefit of humanity.

Looking Ahead: Fix4Bot.com and the Future of Humanoid Robotics

The age of realistic humanoid robots has arrived, and the journey promises to be both exciting and complex. At Fix4Bot.com, we’re prepared to meet the challenges, delivering the expertise and resources needed to keep these remarkable machines operating at their full potential. We are taking the lead in shaping the future of humanoid robot repair, and we invite you to join us as we navigate this transformative technological frontier. Contact us today to discuss your specific needs and learn how Fix4Bot.com can help you maintain and optimize your humanoid robotic systems.

Fake