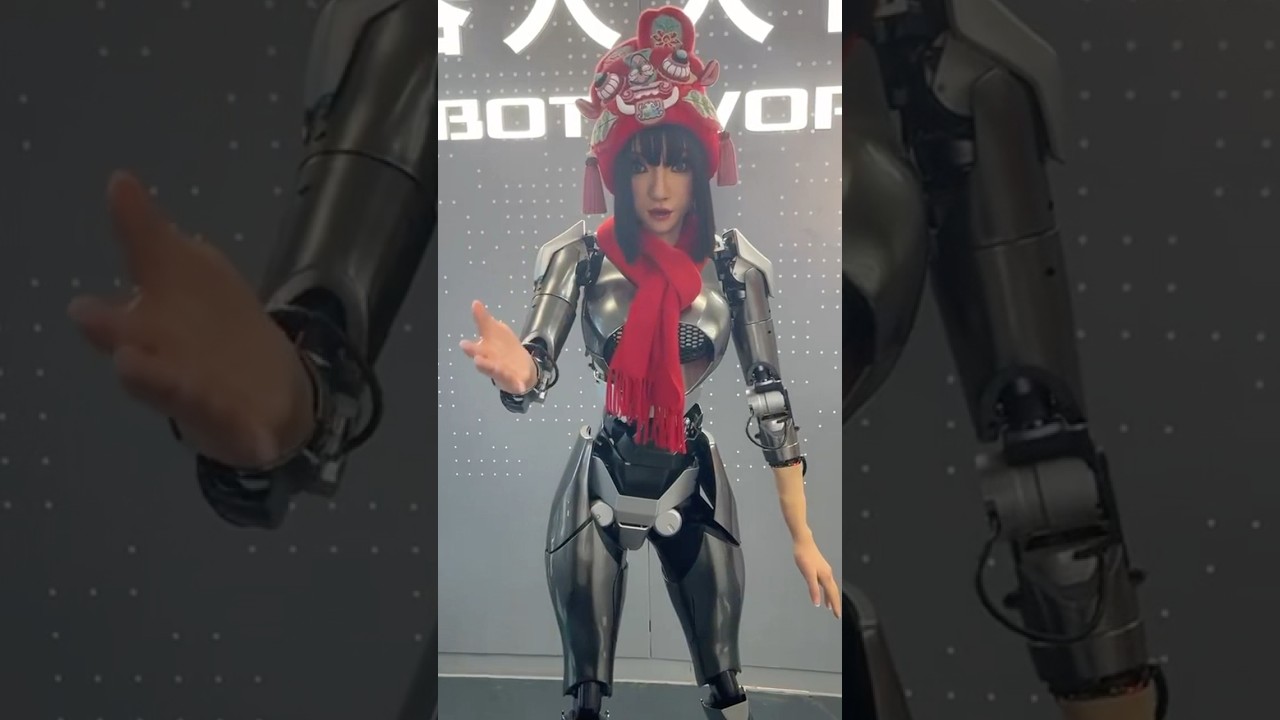

From Glitch to Glory: Restoring Your AI, Robot, and Cosplay Creations with Fix4Bot.com

The intersection of artificial intelligence, robotics, and cosplay is a vibrant, inventive space. From intricate animatronics breathing life into characters to AI-powered companions and self-moving robotic sculptures, the creations emerging from this community are increasingly complex and awe-inspiring. But with complexity comes vulnerability. Accidents happen. Components fail. Software glitches take hold. The dream of a flawlessly functioning creation can quickly transform into a frustrating, even heartbreaking, problem. That’s where Fix4Bot.com steps in. We’re a dedicated resource and service platform specializing in the diagnosis and repair of AI, robotic, and cosplay builds – offering expertise, parts, and a community of makers ready to help restore your projects to their full potential.

The Unique Challenges of AI, Robot, and Cosplay Repair

Unlike typical electronics, these creations often blend mechanics, electronics, software, and artistic design in ways rarely seen elsewhere. A costume malfunctioning during a competition? A robot’s arm seizing mid-performance? An AI unexpectedly generating gibberish? The causes could be multifaceted and demand a specialized skillset. Traditional electronics repair shops rarely possess the breadth of knowledge needed to tackle these hybrid systems.

Here’s a breakdown of the specific challenges they present:

- Mechanical Complexity: Cosplay, especially high-end builds, often incorporates pneumatic systems, servos, custom linkages, and intricate frame designs. Damage here can range from broken actuators to shattered structural elements. Robotics inherently rely on mechanical components, making them susceptible to wear and tear, impact damage, and binding.

- Electronic Integration: The circuitry powering these projects is frequently a patchwork of custom-built boards, off-the-shelf controllers (Arduino, Raspberry Pi, ESP32), sensors, and actuators. Troubleshooting often requires tracing complex signal paths and identifying faulty components within densely packed circuits.

- Software and AI Issues: Programming errors, corrupted data files, and incompatible libraries are common culprits for AI-related malfunctions. Robot control software also faces challenges like sensor drift, control loop instability, and path planning errors. Custom AI models require debugging to ensure accurate and reliable behavior.

- Material Diversity: Building materials encompass everything from laser-cut acrylic and 3D-printed plastics to fabrics, foams, metals, and composites. Repair techniques must be compatible with these diverse materials, considering factors like adhesion, heat sensitivity, and structural integrity.

- Customization & Uniqueness: These projects are rarely stock configurations. Finding replacement parts or schematics can be exceptionally difficult, often requiring custom fabrication or reverse-engineering.

Fix4Bot.com: A Comprehensive Repair Ecosystem

Fix4Bot.com isn’t just a repair service; it’s a complete ecosystem designed to support the creators of AI, robotics, and cosplay projects. We’ve structured our platform around three core pillars: Diagnosis, Repair, and Community.

1. Diagnostics: Pinpointing the Problem

The first step in any effective repair is accurate diagnosis. We offer several approaches:

- Remote Troubleshooting: Our experienced technicians can guide you through initial diagnostics via video conferencing. This allows us to understand the problem’s symptoms, observe the system’s behavior, and suggest potential fixes before escalating to physical repair. We utilize screen sharing and remote access tools (where applicable and with user permission) to assist in software debugging.

- Detailed Photo & Video Analysis: Submitting detailed photos and videos of the malfunctioning component or system gives our diagnostics team a crucial understanding of the physical damage or operational issues. Include details like power supply readings, error messages, and the sequence of events leading to the failure.

- Component Identification & Testing: We maintain a large database of common components used in robotics, AI hardware, and cosplay electronics. Our diagnostics service includes identifying unknown components and performing basic electrical tests (voltage, resistance, continuity) to isolate faults.

- Advanced Diagnostic Tools: For more complex issues, we employ specialized diagnostic equipment, including:

- Oscilloscopes: To visualize voltage signals and identify timing problems in circuits.

- Logic Analyzers: To decode digital signals and troubleshoot microcontroller-based systems.

- Multimeters: For accurate measurement of voltage, current, and resistance.

- Thermal Imaging Cameras: To identify overheating components that may be causing failures.

- Network Analyzers: When dealing with AI driven models

2. Repair Services: Restoring Functionality

Once the diagnosis is complete, a tailored repair plan is developed. Our repair services cover a broad range of needs:

- Mechanical Repairs & Fabrications: Damage to frames, linkages, and other mechanical components is addressed through:

- 3D Printing: Using a wide range of materials (PLA, ABS, PETG, Nylon, TPU) to create replacement parts or custom modifications. We specialize in printing complex geometries and incorporating internal support structures.

- Laser Cutting & Engraving: Fabricating parts from acrylic, wood, and other sheet materials with incredible precision.

- Metal Fabrication: Welding, machining, and other metalworking techniques to repair or fabricate custom metal components.

- Cosplay Armor Repair: Expertise in working with EVA foam, Worbla, fiberglass, and other common cosplay materials. We can repair cracks, dents, and other types of damage, and even recreate entire armor sections.

- Electronics Repair & Refurbishment:

- Component Level Repair: Replacing faulty resistors, capacitors, integrated circuits, and other electronic components using soldering and rework techniques.

- Circuit Board Repair: Repairing traces, pads, and other damage to printed circuit boards (PCBs). We offer PCB duplication services for hard-to-find boards.

- Wiring Harness Repair & Replacement: Replacing damaged or faulty wiring harnesses.

- Controller Programming & Firmware Updates: Identifying and resolving software errors in Arduino, Raspberry Pi, and other microcontroller-based systems. We can update firmware, reprogram controllers, and troubleshoot communication issues.

- AI & Software Solutions:

- Model Debugging & Optimization: Analyzing AI models for bias, errors, and inefficiencies. We can retrain models with new data and optimize them for performance on embedded systems.

- Code Review & Refactoring: Identifying and correcting code errors that lead to unexpected behavior.

- Integration Troubleshooting: Resolving compatibility issues between different software components or hardware sensors.

- Version Control Assistance: Setting up and maintaining version control systems to track changes and facilitate collaborative development.

- Restoration & Customization: Beyond simple repairs, Fix4Bot.com can also help upgrade or customize your projects. This includes adding new features, improving performance, and enhancing aesthetics.

3. Community & Resources: Shared Knowledge & Support

Fix4Bot.com fosters a supportive community of makers and experts:

- Repair Forums: A dedicated forum where users can post questions, share solutions, and collaborate on repair projects.

- Knowledge Base: A growing library of articles, tutorials, and troubleshooting guides covering common problems and repair techniques.

- Parts Marketplace: A curated marketplace where users can buy and sell used or surplus components, 3D printed parts, and other repair supplies.

- Expert Consultations: Connect directly with experienced technicians for personalized advice and guidance.

- DIY Repair Kits: Pre-packaged sets of tools, components, and instructions for common repair tasks.

Repair Techniques and Technology in Detail

Let’s delve deeper into some specific repair techniques and technologies we utilize:

- Micro Soldering and BGA Rework: For repairing surface-mount components (SMDs) on circuit boards, we employ micro soldering equipment and techniques. Ball grid array (BGA) rework, used for replacing complex integrated circuits, requires specialized hot air stations and expertise to avoid damaging the board or components.

- Reverse Engineering: When original schematics or documentation are unavailable, we utilize reverse engineering techniques to understand the circuit’s functionality and identify faulty components. This may involve tracing signal paths, analyzing component values, and simulating the circuit’s behavior.

- 3D Printing Material Selection: Choosing the right 3D printing material is crucial for mechanical repairs. PLA is good for prototyping, but PETG or ABS are more durable for functional parts. Nylon offers high strength and temperature resistance. TPU is ideal for flexible components like gaskets or joints.

- Embedded Systems Debugging: Debugging embedded systems requires specialized tools and techniques. JTAG debuggers allow us to step through code, examine memory contents, and identify errors in real time. Logic analyzers help us monitor the flow of data and control signals.

- AI Model Interpretation & Explainability: Understanding why an AI model is making certain decisions is critical for debugging. We employ techniques like SHAP values and LIME to interpret model outputs and identify potential biases or errors.

- Sensor Calibration & Compensation: Sensors, especially those used in robotics, are prone to drift and inaccuracies. Calibration techniques, such as using known reference values or applying mathematical compensation algorithms, are essential for reliable performance.

Future Directions: Predictive Maintenance and AI-Powered Diagnosis

Fix4Bot.com is committed to continuous improvement and innovation. We are actively developing:

- Predictive Maintenance Programs: Utilizing sensor data (e.g., temperature, vibration, motor current) to predict potential failures before they occur.

- AI-Powered Diagnostic Tools: Developing AI models that can automatically analyze diagnostic data (images, sensor readings, code logs) and suggest potential repairs. This will speed up the diagnosis process and improve accuracy.

- Augmented Reality Repair Guides: Creating interactive AR guides that overlay repair instructions onto the physical device, making the repair process easier and more intuitive.

Conclusion: Keeping Your Creations Alive

The world of AI, robotics, and cosplay is full of creative possibilities. Fix4Bot.com is dedicated to supporting this vibrant community by providing expert repair services, valuable resources, and a collaborative platform. Don’t let a malfunction derail your passion project. Visit Fix4Bot.com today and let us help you get your creation back to its full potential. Your vision deserves to be realized.

Leave A Comment