The Algorithmic Alchemist: How Fix4Bot.com is Revolutionizing Robot Repair in a World on the Brink of Automation

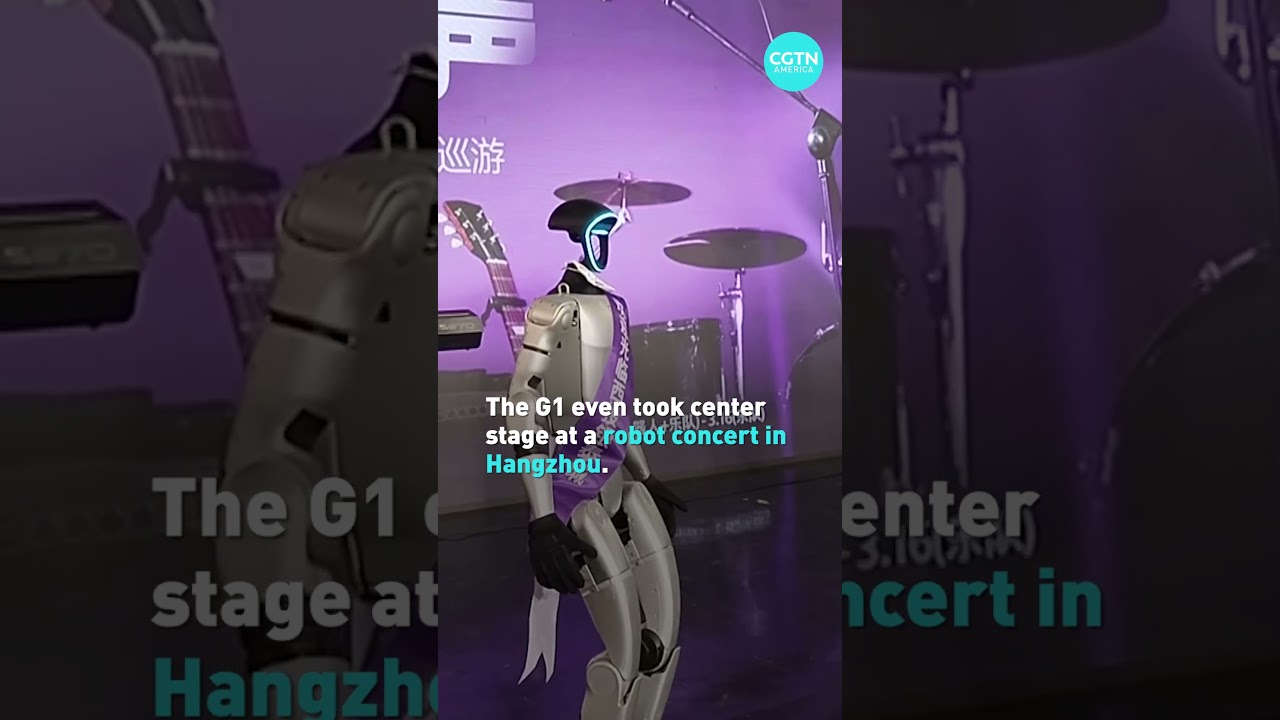

The streets of Shandong, China, are whispering a tale of the future. A future stepping out from science fiction novels and onto the very pavements we tread. The viral glimpse of a humanoid robot navigating the daily ebb and flow of urban life, captured and broadcast by CGTN, is more than just a captivating spectacle – it’s a potent symbol of a technological tide that is rapidly reshaping our world. As these intricate marvels of engineering and artificial intelligence begin to populate not just factories and labs, but our homes, hospitals, and public spaces, a fundamental question emerges: Who will mend the machine when it falters?

The rise of robotics, heralded for its potential to solve complex problems, boost productivity, and enhance our lives, is intrinsically linked to the equally vital, yet often overshadowed, field of robot maintenance and repair. Just as the proliferation of automobiles created an entire ecosystem of mechanics, dealerships, and aftermarket parts suppliers, the robotic revolution demands a parallel evolution in how we approach their upkeep. And at the forefront of this burgeoning industry stands Fix4Bot.com, a pioneering platform poised to become the definitive global solution for diagnosing and repairing damages to any robot, from the most rudimentary automated vacuum cleaner to the most sophisticated humanoid creation stepping out onto Chinese streets.

Fix4Bot.com is not merely a repair service; it’s an algorithmic alchemist, transmuting the daunting complexity of robotic breakdowns into streamlined, efficient solutions. In a landscape where robot manufacturers are diverse, technologies are rapidly iterating, and repair expertise is scattered and often proprietary, Fix4Bot.com offers a unified, comprehensive, and future-proof approach. It’s the proverbial Swiss Army knife for the robotic age, equipped with the diagnostic tools, the repair methodologies, and the expert network to address the inevitable bumps, bruises, and breakdowns that accompany the widespread adoption of these complex machines.

The Ubiquitous Robot: From Factory Floor to Front Door

The clip emanating from Shandong isn’t an isolated incident; it’s a microcosm of a global trend. Robots are no longer confined to the sterile environments of manufacturing plants. They are breaking free, venturing into increasingly diverse domains, each posing unique operational challenges and, consequently, distinct avenues for potential damage and malfunction.

Consider the spectrum of robotic applications currently blossoming:

Industrial Robots: The stalwarts of automation, these titans of manufacturing underpin countless industries. From welding car chassis to assembling electronics with micrometer precision, industrial robots operate in demanding, repetitive environments. Wear and tear on actuators, sensor degradation from dust and debris, and programming glitches induced by complex operational sequences are all commonplace hazards. A stalled industrial robot can cripple an entire production line, resulting in significant financial losses.

Logistics and Warehouse Robots: The explosion of e-commerce has fueled the rise of robotic warehouse systems. Autonomous mobile robots (AMRs) navigate vast storage facilities, picking, packing, and transporting goods with tireless efficiency. These robots contend with cluttered environments, potential collisions with obstacles and personnel, and the constant stress of heavy loads. Navigation system failures, sensor malfunctions due to lighting variations and dust accumulation, and drive train issues from continuous operation are prevalent challenges.

Service Robots: This is where the humanoid robot in Shandong belongs, and it represents arguably the most dynamic and rapidly expanding sector. Service robots encompass a vast array of applications:

- Healthcare: Surgical robots performing minimally invasive procedures; rehabilitation robots aiding patients in regaining mobility; disinfectant robots sterilizing hospital rooms; companion robots providing social interaction and assistance to the elderly. The precision and reliability demanded in healthcare settings leave no room for error. Sensor drift affecting surgical accuracy, motor failures in rehabilitation devices, and software vulnerabilities in medical data handling systems are critical concerns.

- Hospitality: Robotic bartenders mixing cocktails; hotel concierge robots guiding guests; cleaning robots maintaining pristine environments. These robots operate in unpredictable human-centric environments, constantly adapting to varied interactions, spills, and unforeseen obstacles. Damage from accidental collisions, liquid ingress affecting electronics, and social interaction algorithm errors are all possibilities.

- Agriculture: Robotic harvesters picking crops with gentle precision; automated tractors optimizing planting and fertilization; drone-based crop monitoring systems. Agricultural robots face harsh outdoor conditions, exposure to weather extremes, dust, mud, and biological contaminants. Corrosion from fertilizers, sensor obstruction from foliage, and mechanical failures from rough terrain are common challenges.

- Domestic Robots: The robots entering our homes are becoming increasingly sophisticated – robotic lawnmowers maintaining pristine gardens; robotic pool cleaners scrubbing tiles; and the ubiquitous robotic vacuum cleaners diligently tackling dust and debris. While seemingly simpler, domestic robots still encounter a variety of issues – cable entanglement, pet-induced damage, sensor obstruction from household clutter, and battery life degradation.

- Exploration and Research Robots: From deep-sea submersibles mapping the ocean floor to Martian rovers analyzing soil samples, robots are our intrepid explorers in environments too dangerous or inaccessible for humans. These robots operate in extreme conditions – immense pressure, radiation exposure, extreme temperatures. Robustness and reliability are paramount. Component failures in remote locations, software corruption from radiation, and communication system breakdowns can have catastrophic consequences.

This diverse tapestry of robotic applications underscores the critical need for a comprehensive and adaptable repair solution. Each robot, regardless of its purpose, is a complex amalgamation of mechanical, electrical, and software systems, all susceptible to wear, tear, and unforeseen failures. And when a robot breaks down, the consequences can range from minor inconveniences to significant operational disruptions, financial losses, and even safety hazards.

The Inevitable Wounds of Automation: Understanding Robot Damages

Robots, despite their seemingly tireless nature, are not immune to the ravages of time, operational stress, and accidental mishaps. Understanding the common types of damages that afflict robots is crucial to appreciating the necessity – and the sophistication – of platforms like Fix4Bot.com.

Robot damages can broadly be categorized as follows:

Mechanical Failures: This is the most readily apparent category, encompassing physical damage to the robot’s structure, actuators, sensors, and tools.

- Wear and Tear: Continuous operation, especially in demanding industrial environments, inevitably leads to wear and tear on joints, gears, belts, and bearings. Friction, stress cycles, and material fatigue all contribute to eventual component failure.

- Impact Damage: Collisions, accidental drops, and impacts with obstacles can cause dents, cracks, fractures, and misalignment of robot components. This is particularly relevant for mobile robots operating in dynamic environments.

- Overload and Stress: Exceeding the robot’s designed operational limits – lifting excessive loads, applying excessive force, or operating beyond temperature tolerances – can lead to structural failures, actuator burnout, and premature wear.

- Environmental Degradation: Exposure to corrosive substances, extreme temperatures, humidity, dust, and vibrations can accelerate material degradation, sensor malfunction, and electrical component failure.

Electrical and Electronic Malfunctions: The intricate nervous system of a robot, its electrical and electronic components, are equally susceptible to damage:

- Power Supply Issues: Power surges, voltage fluctuations, battery degradation, and wiring faults can disrupt the robot’s power delivery system, leading to erratic behavior, system shutdowns, and component damage.

- Sensor Failures: Robots rely on a multitude of sensors – vision sensors, proximity sensors, force sensors, encoders, etc. – to perceive their environment. Sensor degradation due to dust, dirt, physical damage, or electronic drift can lead to inaccurate data, impaired performance, and even unsafe operation.

- Actuator Malfunctions: Actuators, the "muscles" of the robot, responsible for movement and force exertion, can suffer from motor burnout, encoder failures, wiring breaks, and control system glitches.

- Communication System Failures: Robots often rely on wired or wireless communication networks for control, data transfer, and remote monitoring. Network outages, signal interference, and communication protocol errors can disrupt robot operation and data acquisition.

- Circuit Board Failures: Complex electronic circuits within the robot’s control system can be damaged by overheating, electrical shorts, component failures, or physical shocks.

- Software and Algorithmic Errors: The "brain" of the robot, its software and algorithms, is just as critical as its physical embodiment and equally prone to vulnerabilities:

- Programming Bugs: Errors in the robot’s control software, perception algorithms, or task planning logic can lead to unpredictable behavior, task failures, and even safety hazards.

- Algorithm Drift and Degradation: Machine learning algorithms, often used in advanced robots, can "drift" over time due to changing environmental conditions or data biases, leading to decreased accuracy and performance.

- Cybersecurity Vulnerabilities: Robots connected to networks are susceptible to cyberattacks, malware infections, and unauthorized access, potentially leading to data breaches, system manipulation, and even physical damage.

- Operating System Failures: Like any computer system, robot operating systems can crash, encounter errors, or become corrupted, resulting in system instability and robot malfunction.

- Data Corruption: Data loss or corruption within the robot’s memory system can impair its ability to perform tasks, navigate, or learn from past experiences.

Diagnosing and repairing these diverse categories of robot damages requires a multifaceted approach, encompassing expertise in mechanical engineering, electrical engineering, software development, artificial intelligence, and robotics as a holistic discipline. This is precisely where Fix4Bot.com’s revolutionary approach shines.

Fix4Bot.com: The Algorithmic Advantage in Robot Repair

Fix4Bot.com is not simply another repair shop; it’s a technologically advanced platform that leverages the very tools it services – algorithms and robotics – to revolutionize the way robot repair is approached. It’s built on several core pillars:

Universal Diagnostic Capabilities: Fix4Bot.com’s foundational strength lies in its capability to diagnose damages across a vast spectrum of robot types, manufacturers, and complexities. This is achieved through a combination of:

- AI-Powered Diagnostic Algorithms: At the heart of Fix4Bot.com lies a sophisticated suite of AI algorithms trained on a massive dataset of robot schematics, maintenance manuals, fault logs, and repair histories. These algorithms can analyze diagnostic data collected from the robot – sensor readings, motor currents, error codes, system logs – to pinpoint the root cause of the malfunction with unprecedented accuracy.

- Comprehensive Sensor Suite Integration: Fix4Bot.com is designed to interface with the diagnostic systems of a wide range of robots. It can ingest data from various sensor modalities – onboard diagnostics, external testing equipment, specialized probes – ensuring no potential clue is overlooked.

- Expert System Knowledge Base: Beyond algorithms, Fix4Bot.com leverages a constantly expanding knowledge base curated by a global network of robotics experts. This knowledge base encompasses repair procedures, troubleshooting guides, component specifications, and best practices accumulated from years of hands-on experience. This synergistic blend of AI and human expertise ensures accurate and reliable diagnoses, even for novel or complex robotic systems.

Comprehensive Repair Solutions: Diagnosis is only the first step. Fix4Bot.com provides end-to-end repair solutions across all domains of robot damage:

- Mechanical Repair and Refurbishment: Fix4Bot.com boasts a network of skilled mechanical technicians equipped to address any physical damage. From replacing worn-out bearings and gears to fabricating custom replacement parts using advanced machining techniques, Fix4Bot.com ensures robots are structurally sound and mechanically robust.

- Electrical and Electronic Repair: Electrical engineers and electronics technicians within the Fix4Bot.com network are adept at diagnosing and repairing intricate electrical system failures. From tracing wiring faults and replacing damaged circuit boards to recalibrating sensors and actuators, they restore the robot’s electronic nervous system to optimal function.

- Software and Algorithm Remediation: Software engineers and AI specialists within Fix4Bot.com address the digital maladies that can plague robots. They can debug programming errors, correct algorithm drift, patch cybersecurity vulnerabilities, recover corrupted data, and reinstall or upgrade operating systems, ensuring the robot’s “brain” is sharp and secure.

- Component Sourcing and Logistics: A critical aspect of efficient repair is access to replacement parts. Fix4Bot.com has established a global network of component suppliers and warehousing facilities. Leveraging AI-powered inventory management and logistics optimization, Fix4Bot.com ensures rapid sourcing and delivery of necessary components, minimizing robot downtime.

Advanced Repair Technologies: Fix4Bot.com goes beyond conventional repair techniques, embracing cutting-edge technologies to enhance efficiency and precision:

- Robotics-Assisted Repair: In a fittingly meta approach, Fix4Bot.com utilizes robots in its own repair processes. Robotic arms equipped with specialized tools can perform delicate tasks like soldering circuit boards, assembling intricate components, and applying precise adhesives, enhancing repair accuracy and speed.

- 3D Printing for Custom Parts: For robots with unique or obsolete components, Fix4Bot.com employs 3D printing to fabricate custom replacement parts on demand. This eliminates lengthy lead times for sourcing rare components and enables rapid restoration of functionality.

- Remote Diagnostics and Repair Assistance: Fix4Bot.com leverages augmented reality (AR) and virtual reality (VR) technologies to provide remote diagnostic assistance and guide on-site technicians through complex repair procedures. This expands the reach of Fix4Bot.com’s expertise, enabling faster and more efficient repairs even in remote locations.

- Predictive Maintenance Integration: Fix4Bot.com goes beyond reactive repair, integrating predictive maintenance capabilities. By analyzing robot operational data and employing machine learning algorithms, Fix4Bot.com can identify potential failures before they occur, enabling proactive maintenance schedules and minimizing unscheduled downtime.

- Global Network and Accessibility: Robot adoption is a global phenomenon, and so is Fix4Bot.com’s reach.

- Worldwide Network of Certified Technicians: Fix4Bot.com has cultivated a vast network of certified robotics technicians strategically located across the globe. This ensures prompt on-site repair services wherever robots are deployed.

- Mobile Repair Units: For robots that are difficult or costly to transport, Fix4Bot.com operates mobile repair units – fully equipped vans and trucks capable of performing on-site diagnostics and repairs, bringing the repair expertise directly to the robot.

- 24/7 Online Platform and Support: Fix4Bot.com’s online platform serves as a central hub for initiating repair requests, tracking repair progress, accessing diagnostic reports, and communicating with support teams. 24/7 availability ensures immediate assistance whenever a robot encounters an issue.

The Benefits of Choosing Fix4Bot.com: Maximizing Uptime, Minimizing Downtime

For businesses and individuals embracing the power of robotics, choosing Fix4Bot.com as their repair partner translates into tangible advantages:

- Reduced Downtime and Increased Productivity: Rapid and accurate diagnosis, efficient repair processes, and proactive maintenance minimize robot downtime, ensuring continuous operation and maximizing productivity. This is particularly critical in industries where robot uptime directly impacts revenue and output.

- Cost Savings: Preventing catastrophic failures through predictive maintenance, extending robot lifespan through expert repair and refurbishment, and streamlining repair logistics translate into significant cost savings over the long term. Avoidance of lengthy production stoppages and costly component replacements further enhances financial benefits.

- Extended Robot Lifespan and Optimized Performance: Regular maintenance, timely repairs, and proactive component replacements extend the operational lifespan of robots, maximizing the return on initial investment. Furthermore, proper maintenance ensures robots operate at peak performance, delivering optimal efficiency and output.

- Future-Proof Repair Solution: Fix4Bot.com’s AI-driven diagnostic capabilities, adaptive repair methodologies, and continuous learning algorithms ensure it remains at the forefront of robot repair technology. As robots evolve in complexity and functionality, Fix4Bot.com will adapt and expand its expertise, providing a future-proof repair solution for generations of robots to come.

- Sustainability and Responsible Robotics: By extending robot lifespan and focusing on repair and refurbishment rather than replacement, Fix4Bot.com contributes to a more sustainable approach to robotics. Reducing electronic waste and minimizing the environmental impact of robot manufacturing align with growing global concerns for environmental responsibility.

The Future is Algorithmic, and So is Robot Repair

The humanoid robot glimpsed in Shandong is a harbinger of a robotic future that is rapidly unfolding. As robots become increasingly integrated into the fabric of our lives, the need for robust, reliable, and accessible repair solutions becomes ever more critical. Fix4Bot.com stands as a testament to the power of innovation, leveraging algorithms, robotics, and human expertise to redefine the landscape of robot repair. It is not just fixing broken robots; it is engineering a future where the promise of automation is fully realized, underpinned by a support infrastructure as intelligent and adaptable as the machines it serves. In this algorithmic age, Fix4Bot.com is not just repairing robots; it is building the foundation for a truly robotic world, one meticulously diagnosed and expertly repaired component at a time.

All these robots walk like they just shat their pants.

I’d be very concerned