Beyond Bricks and Mortar: Fix4Bot.com – Your Specialized Savior for Advanced Humanoid Robots

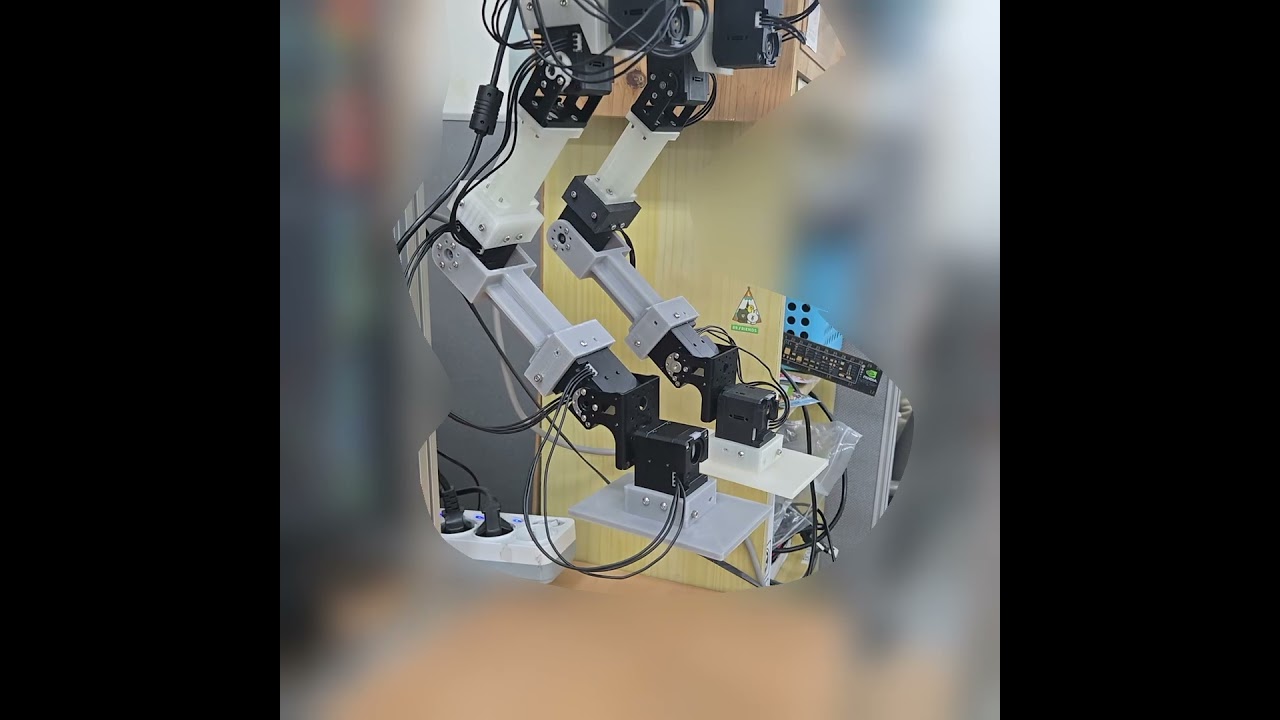

In an age where the intricate dance of circuits and code is increasingly shaping our world, the rise of humanoid robotics represents a tantalizing leap towards a future once confined to the realms of science fiction. These sophisticated machines, mimicking the very form of humanity, are no longer mere laboratory curiosities. They are emerging as powerful tools across research, industry, and even personal assistance, promising to revolutionize how we interact with technology and the world around us. However, with such advanced innovation comes a critical, often overlooked, imperative: maintenance and repair. The complexity inherent in these humanoid marvels demands not just generic tech support, but specialized expertise, a deep understanding of their unique architectures, and a dedication to keeping them operational at peak performance. This is where Fix4Bot.com emerges as the definitive solution, a dedicated sanctuary of robotic repair and diagnostics uniquely positioned to breathe life back into your advanced humanoid robots, particularly those masterfully crafted using 3D-printed components, driven by the elegance of position-based walking via the Linear Inverted Pendulum Model (LIPM), orchestrated by the versatile Robot Operating System 2 (ROS2), and brought to life by the precision of Robotis servo motors.

Fix4Bot.com isn’t just another repair shop. We are a collective of robotics engineers, software specialists, and mechatronics experts who live and breathe robotics. We understand the intricate symphony of hardware and software that makes your humanoid robot function, and we are passionately dedicated to ensuring its continued performance, regardless of the challenges it faces. When your sophisticated machine encounters a hiccup, a stumble, or a complete system failure, Fix4Bot.com is your unwavering lifeline, offering a comprehensive suite of diagnostic and repair services tailored specifically to the nuances of advanced humanoid robotics, particularly those built upon the innovative foundation described.

Delving into the Anatomy of the Advanced Humanoid: Understanding the Vulnerabilities

To truly appreciate Fix4Bot.com’s expertise, it’s crucial to understand the specific challenges inherent in repairing a humanoid robot built using 3D-printed parts and governed by the LIPM-based walking, ROS2 control, and Robotis servo actuation. Each of these elements, while constituting a brilliant framework, also introduces unique points of potential vulnerability.

1. The Fragile Fabric of 3D-Printed Components:

The very essence of many modern humanoid robots lies in the groundbreaking accessibility and design freedom offered by 3D printing. Building components layer by layer allows for intricate geometries, customized designs, and rapid prototyping, fundamentally changing how robots are conceived and constructed. However, this revolutionary approach also brings a distinct set of repair challenges.

Material Limitations: While 3D printing materials are constantly evolving, common polymers like PLA, ABS, PETG, and even more advanced composites have inherent limitations in strength, durability, and resistance to various stresses. Impact, repetitive stress, temperature fluctuations, and UV exposure can all degrade 3D-printed parts over time, leading to cracks, fractures, warping, and eventual failure. Fix4Bot.com technicians possess an in-depth understanding of the material properties of various 3D printing filaments and are adept at identifying material degradation and structural weaknesses. We can assess the type of filament used, identify stress points, and determine the most effective repair or replacement strategy, ensuring the structural integrity of your robot is restored.

Layer Delamination and Weak Points: The layered nature of 3D printing can, under certain conditions, create weak points where layers don’t fully adhere, leading to delamination or cracking along layer lines. Improper printing parameters, material incompatibility, or even environmental factors can contribute to this. Fix4Bot.com’s diagnostic process includes meticulous inspection of 3D-printed parts, identifying potential delamination points through visual inspection, non-destructive testing techniques like ultrasonic analysis (where appropriate and feasible), and stress testing simulations. We can meticulously repair delaminated layers using specialized adhesives and reinforcement techniques, or, when necessary, precisely replicate and replace the damaged part using our own in-house 3D printing capabilities, ensuring perfect fit and material compatibility.

- Complex Geometries and Intricate Designs: While beneficial, the intricate geometries enabled by 3D printing can also make repairs more complex. Internal channels for wiring, delicate joints, and thin-walled structures require specialized repair techniques. Fix4Bot.com engineers are trained in handling these complex designs. We utilize precision tools, micro-soldering equipment, and advanced bonding agents to access and repair even the most intricately designed 3D-printed components without causing further damage. Our expertise extends to reinforcing vulnerable areas in future replacements, if necessary, improving the overall robustness of the robot.

2. The Delicate Balance of LIPM-Based Walking:

The Linear Inverted Pendulum Model (LIPM) is a cornerstone of bipedal locomotion, simplifying the complex dynamics of walking into a manageable mathematical framework. It treats the robot as an inverted pendulum, balancing on a single point of support. While computationally efficient and effective for generating walking gaits, LIPM-based systems are sensitive to various factors that can disrupt their delicate equilibrium.

Sensor Calibration and Accuracy: LIPM relies heavily on accurate sensor data from IMUs (Inertial Measurement Units), encoders in servo motors, and potentially force/torque sensors. Drifts in sensor calibration, noise in sensor readings, or outright sensor failures can directly impact the LIPM’s ability to maintain balance and generate stable walking patterns. This can manifest as jerky movements, instability, falls, or a complete inability to walk. Fix4Bot.com possesses specialized calibration tools and procedures for all relevant sensors used in LIPM-based robots. We meticulously diagnose sensor accuracy, identify drifts or biases, and recalibrate sensors to factory specifications or even optimize them for enhanced performance. We can also replace faulty sensors with high-quality, compatible components, ensuring the LIPM receives accurate and reliable data.

Joint Kinematics and Actuator Precision: LIPM calculations dictate precise joint movements for stable walking. Issues with the robot’s kinematic structure (e.g., misaligned joints due to manufacturing tolerances or damage) or inaccuracies in servo motor actuation (due to wear, gear stripping, or control board failures) can introduce errors that destabilize the LIPM. Fix4Bot.com’s diagnostic process includes detailed kinematic analysis and joint inspection. We utilize laser measurement systems and precision alignment tools to verify joint positions and identify any deviations from design specifications. We are experts in Robotis servo motor repair, capable of diagnosing issues at the component level, replacing gears, repairing control boards, and ensuring precise encoder feedback. If a servo is beyond repair, we source and replace it with a genuine Robotis component, guaranteeing kinematic accuracy and optimal LIPM performance.

- Parameter Tuning and Control System Issues: The LIPM is parameterized, requiring careful tuning of gains and thresholds for stable walking. Software bugs in the control code, incorrect parameter settings, or even subtle changes in the robot’s physical parameters (e.g., weight distribution after a repair) can disrupt the carefully tuned LIPM. Fix4Bot.com engineers are deeply versed in LIPM control algorithms and parameter tuning techniques. We utilize ROS2’s powerful debugging and introspection tools to analyze the robot’s control system, identify parameter discrepancies, and optimize LIPM parameters for stable and efficient walking, even after significant repairs or component replacements. We can also diagnose and resolve software bugs within the ROS2 control code itself, ensuring the LIPM operates flawlessly.

3. The ROS2 Software Ecosystem and its Intricacies:

Robot Operating System 2 (ROS2) is the de facto standard software framework for robotics research and development. Its modular architecture, rich toolset, and vibrant community make it ideal for controlling complex humanoid robots. However, the very power and flexibility of ROS2 also introduce potential software-related failure points.

Node Crashes and Communication Issues: ROS2’s distributed architecture relies on robust communication between various software nodes. A crash in a critical node (e.g., the LIPM controller, sensor data processing node, or motor control node) or communication failures between nodes due to network issues or DDS (Data Distribution Service) problems can bring the robot’s operation to a standstill. Fix4Bot.com’s ROS2 expertise is paramount. We are proficient in debugging ROS2 node crashes, utilizing ROS2’s logging and introspection tools to pinpoint the root cause. We diagnose and resolve communication issues by analyzing network configurations, DDS settings, and node communication patterns. Our goal is to restore seamless communication and ensure the entire ROS2 software ecosystem functions harmoniously.

Software Bugs and Package Dependencies: Complex ROS2 projects often rely on numerous software packages, some of which may be custom-developed or sourced from external repositories. Software bugs within the ROS2 codebase, package dependency conflicts, or version incompatibilities can lead to unpredictable behavior and system failures. Fix4Bot.com’s software engineers are adept at navigating the complexities of ROS2 software environments. We are skilled in debugging software bugs using code analysis tools, unit testing, and system-level integration testing. We meticulously manage package dependencies, resolving conflicts and ensuring compatibility. We maintain a comprehensive knowledge base of common ROS2 issues and their solutions, allowing for rapid diagnosis and resolution of software-related problems.

- Configuration Errors and Parameter Mismatches: ROS2’s flexibility allows for extensive configuration and parameterization. Misconfigurations in ROS2 launch files, node parameters, or system settings can lead to subtle but debilitating issues that are difficult to diagnose. Fix4Bot.com technicians possess a deep understanding of ROS2 configuration conventions and best practices. We meticulously review ROS2 configurations, identifying and correcting errors, ensuring parameters are correctly set for optimal robot performance. We can even optimize ROS2 configurations for improved efficiency and responsiveness.

4. Robotis Servo Motors: Precision Actuation and Potential Pitfalls:

Robotis Dynamixel servo motors are renowned for their precision, reliability, and integrated control capabilities, making them a popular choice for humanoid robot actuation. However, even these high-quality servos are not immune to wear and tear or potential failures.

Gear Stripping and Mechanical Wear: Despite robust gear trains, Robotis servos can experience gear stripping under excessive loads or impacts. Mechanical wear over time, especially in heavily used joints, can also lead to backlash and reduced precision. Fix4Bot.com’s servo repair expertise extends to the mechanical level. We meticulously disassemble Robotis servos, inspect gear trains for damage, and replace stripped or worn gears with genuine Robotis replacement parts. We lubricate gear trains, check for proper bearing function, and reassemble servos to factory specifications, restoring their mechanical integrity and precision.

Control Board Failures and Encoder Issues: The integrated control boards within Robotis servos can fail due to electrical surges, overheating, or component degradation. Encoder failures can disrupt position feedback, leading to inaccurate movements and control issues. Fix4Bot.com possesses specialized electronic diagnostic equipment for Robotis servo control boards. We can diagnose component-level failures on servo PCBs, replacing faulty components like microcontrollers, MOSFETs, and sensors. We also diagnose and repair encoder issues, ensuring accurate position feedback is restored, enabling precise and reliable servo control.

- Wiring and Connector Problems: The numerous servo motors in a humanoid robot necessitate complex wiring and connector systems. Loose connections, frayed wires, or damaged connectors can disrupt servo communication and power, leading to erratic behavior or complete servo failure. Fix4Bot.com technicians pay meticulous attention to detail when inspecting wiring and connectors. We identify and repair loose connections, replace damaged wires and connectors, and ensure robust electrical connections throughout the robot’s servo system. We utilize high-quality wiring and connectors that meet or exceed the original specifications, guaranteeing reliable servo operation.

Fix4Bot.com: Your Comprehensive Repair Arsenal

Armed with a profound understanding of these potential vulnerabilities, Fix4Bot.com has assembled a comprehensive arsenal of diagnostic tools, repair techniques, and expert personnel specifically tailored to address the challenges of advanced humanoid robot maintenance.

1. Advanced Diagnostic Capabilities:

Multi-Modal Sensor Diagnostics: We utilize a suite of sensor testing equipment to evaluate the accuracy and health of IMUs, encoders, force/torque sensors, and other sensory inputs crucial for LIPM walking and overall robot operation. This includes precision calibration equipment, noise analysis tools, and signal integrity testers.

Non-Destructive Testing (NDT) for 3D-Printed Parts: Where appropriate and feasible, we employ NDT techniques like ultrasonic analysis to identify internal cracks or delamination in 3D-printed parts without causing further damage during inspection.

ROS2 System Introspection and Debugging Tools: We leverage the full power of ROS2’s command-line interface (CLI), logging system, introspection tools (like rqt), and debugging utilities (like gdb and valgrind) to deeply analyze the robot’s software state, identify node crashes, communication bottlenecks, and software bugs.

Servo Motor Diagnostic Station: We have designed a dedicated servo motor diagnostic station equipped with dynamometers, encoder testers, and control signal analyzers for in-depth evaluation of Robotis servo performance. This allows us to pinpoint mechanical, electrical, and control-related servo issues with precision.

- Kinematic Measurement and Alignment Systems: We employ laser measurement systems and precision alignment tools to accurately measure joint positions, arm lengths, and other kinematic parameters, identifying deviations from design specifications and ensuring proper robot geometry.

2. Expert Repair Techniques:

Specialized 3D-Printed Part Repair and Replication: We are proficient in repairing fractured 3D-printed parts using specialized adhesives, patching techniques, and reinforcement methods. When repairs are not feasible or structural integrity is compromised, we utilize our in-house 3D printing facilities to precisely replicate and replace damaged parts, ensuring material compatibility and perfect fit. We can also utilize more durable materials or design modifications for improved robustness in replacement parts upon request.

Component-Level Robotis Servo Repair: Our technicians are trained in component-level repair of Robotis servo motors. We go beyond simple board swapping, replacing individual components on servo control boards, repairing gear trains, and addressing encoder issues. This approach minimizes repair costs and reduces electronic waste.

ROS2 Software Debugging and Optimization: Our software engineers are experts in ROS2 debugging, capable of resolving complex software bugs, optimizing ROS2 configurations for performance, and developing custom ROS2 tools and packages as needed to enhance robot functionality or diagnose specific issues.

Precision Wiring and Connector Repair: We are meticulous in our wiring and connector repairs, utilizing high-quality wiring, connectors, and soldering techniques to restore robust and reliable electrical connections throughout the robot. We adhere to industry best practices for cable management and strain relief to minimize future wiring issues.

- LIPM Parameter Re-tuning and Gait Optimization: Our expertise extends to re-tuning LIPM parameters after repairs or component replacements. We can optimize gaits for stability, speed, and energy efficiency, ensuring the robot’s walking performance is maximized.

3. Proactive Maintenance and Preventative Strategies:

Fix4Bot.com believes in not just reactive repair, but also proactive maintenance to prevent future issues and extend the lifespan of your humanoid robot. We offer:

Regular Robot Health Check-ups: We provide comprehensive robot health check-up services, including sensor calibration verification, joint inspection, software system audits, and proactive identification of potential wear and tear.

Preventative Maintenance Programs: We design customized preventative maintenance programs tailored to the specific usage patterns of your robot, including scheduled lubrication, component inspections, and software system updates.

- Training and Consultation: We offer training programs for your team on basic robot maintenance procedures, troubleshooting common issues, and understanding best practices for robot operation and care. We also provide expert consultation on robot design improvements for enhanced durability and maintainability.

Why Choose Fix4Bot.com?

Fix4Bot.com is not just a repair service; we are your dedicated partner in ensuring the continued operational excellence of your advanced humanoid robots. We offer:

Specialized Expertise: Our focus is exclusively on advanced humanoid robots, allowing us to develop deep, nuanced expertise in their unique architectures and repair requirements.

Comprehensive Solutions: We offer a complete suite of diagnostic, repair, and preventative maintenance services, addressing issues at every level, from 3D-printed parts to ROS2 software and servo motor components.

Component-Level Repair: Our commitment to component-level repair minimizes costs, reduces electronic waste, and allows us to restore functionality to even complex electronic systems.

Proactive Approach: We prioritize preventative maintenance and proactive strategies to minimize downtime and maximize the lifespan of your valuable robotic assets.

- Experienced and Passionate Team: Our team comprises highly skilled and passionate robotics engineers, software specialists, and mechatronics experts who are dedicated to providing exceptional service and ensuring the success of your robotics endeavors.

In conclusion, the intricate world of advanced humanoid robots demands specialized care and expertise. When your sophisticated machine requires attention, Fix4Bot.com stands ready as your unwavering partner, providing the knowledge, tools, and dedication necessary to diagnose, repair, and maintain your robot, ensuring it continues to push the boundaries of innovation and realize its full potential. Contact Fix4Bot.com today and experience the peace of mind that comes with knowing your humanoid robot is in the hands of true experts. Let us be the architects of its continued operation, ensuring its intricate dance of circuits and code remains a harmonious and productive force in your world.

Leave A Comment