\boxed{“`html

How Fix4Bot.com Can Diagnose and Repair Damages to Your Humanoid Robot

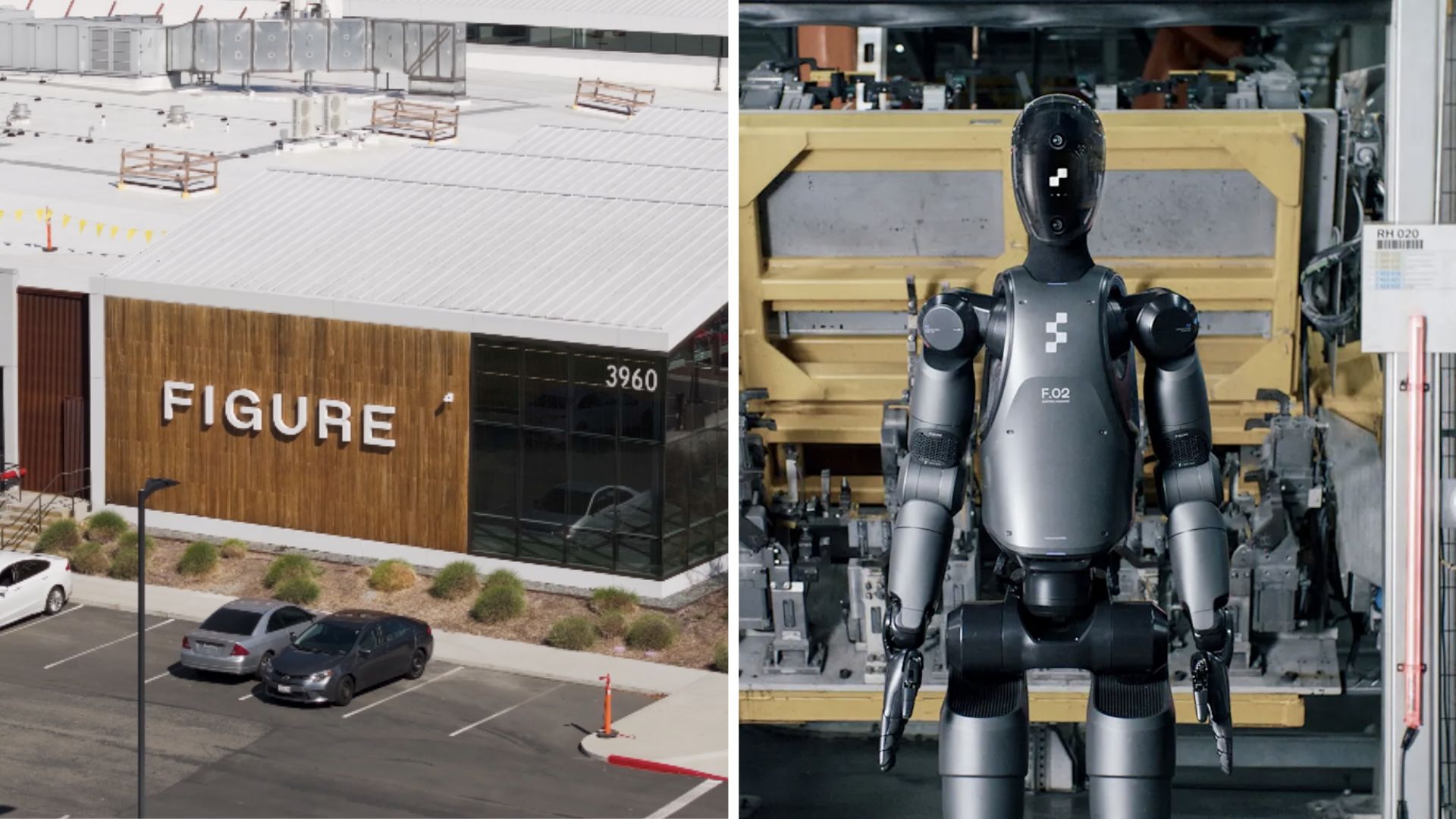

In the rapidly evolving world of robotics, the need for reliable and efficient repair services has never been more critical. As California-based Figure announces the development of a new high-volume BotQ robot manufacturing facility designed to produce up to 12,000 humanoid robots per year, the question arises: what happens when these advanced robots need maintenance or repair? Enter Fix4Bot.com, a cutting-edge service dedicated to diagnosing and repairing any damages to your humanoid robots.

The Rise of BotQ and the Need for Specialized Repair Services

Figure’s new BotQ facility is a testament to the company’s commitment to vertical integration, a business strategy where a company controls multiple stages of its supply chain, from raw materials to end-product distribution. This allows Figure to maintain tight control over robot quality, production efficiency, and performance. However, even the most well-designed and well-manufactured robots can encounter issues that require expert attention.

The BotQ Manufacturing Facility

The BotQ facility is designed to produce humanoid robots on a large scale. The first-generation line aims to manufacture up to 12,000 humanoid robots annually, with plans to increase production significantly. The facility uses a variety of advanced software platforms such as a Manufacturing Execution System (MES) for real-time control and tracking of production lines, Product Lifecycle Management (PLM) for overseeing the robot lifecycle from design to manufacturing, Enterprise Resource Planning (ERP) for managing resources, scheduling, and logistics, and a Warehouse Management System (WMS) for optimizing inventory management.

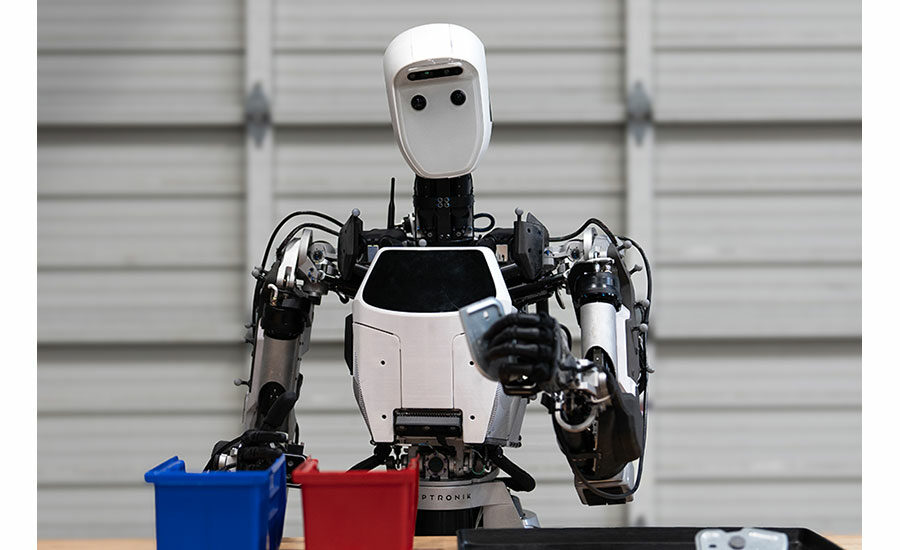

The Role of Humanoid Robots in Manufacturing

One of the most innovative aspects of the BotQ facility is the use of humanoid robots to assist in manufacturing additional robots. This “robots building robots” approach aims to increase automation, speed up production, and reduce human involvement in repetitive tasks. However, this also means that any malfunction in a single robot could potentially disrupt the entire production line. This is where Fix4Bot.com comes into play.

How Fix4Bot.com Diagnoses and Repairs Damages

Advanced Diagnostic Tools

Fix4Bot.com employs a suite of advanced diagnostic tools designed specifically for humanoid robots. These tools can quickly identify issues ranging from mechanical failures to software glitches. The diagnostic process typically involves:

- Initial Assessment: A preliminary check to identify any obvious physical damages or malfunctions.

- Software Diagnostics: Running a series of tests to check the robot’s software for any bugs or errors.

- Hardware Diagnostics: Using specialized equipment to test the robot’s hardware components such as motors, sensors, and batteries.

- Performance Testing: Ensuring that the robot can perform all its intended tasks efficiently.

Repair Techniques and Technology

Once a problem is identified, Fix4Bot.com utilizes a variety of repair techniques and technologies to restore the robot to optimal working condition. These include:

1. Component Replacement

For hardware issues, Fix4Bot.com has a vast inventory of parts specifically designed for Figure’s humanoid robots. Whether it’s a faulty motor, a damaged sensor, or a worn-out battery, the service can quickly replace the defective component with a new one.

2. Software Updates and Patching

Software issues can often be resolved through updates or patches. Fix4Bot.com works closely with Figure to ensure that any software bugs are promptly addressed. The service can also perform firmware updates to keep the robot’s software up-to-date with the latest features and security patches.

3. Mechanical Repairs

For mechanical issues such as misaligned joints or damaged limbs, Fix4Bot.com employs a team of skilled technicians who are trained in the specific mechanical design of Figure’s humanoid robots. They can perform precise adjustments and repairs to ensure that the robot’s movements are smooth and accurate.

4. Battery Maintenance and Replacement

Batteries are a critical component of any humanoid robot. Fix4Bot.com offers battery testing, maintenance, and replacement services. The company uses advanced battery cell testing and handling techniques to ensure that the robot’s power source is reliable and long-lasting.

5. Preventive Maintenance

To prevent future issues, Fix4Bot.com offers preventive maintenance services. This includes regular check-ups, part replacements before they fail, and software updates. Preventive maintenance can significantly extend the lifespan of a humanoid robot and ensure that it operates at peak efficiency.

The Importance of Specialized Repair Services

Given the complexity of humanoid robots, specialized repair services like Fix4Bot.com are essential. These robots are not only made up of numerous mechanical parts but also rely heavily on sophisticated software. A general repair service might not have the expertise or the parts necessary to properly diagnose and fix issues in a humanoid robot.

The Future of Humanoid Robot Manufacturing and Repair

As Figure transitions from its prototype humanoid robot, Figure 02, to its production-ready robot, Figure 03, the need for efficient and reliable repair services will only grow. The new robot features a more straightforward design to reduce the number of parts and simplify assembly. However, this does not eliminate the need for expert repair services.

The Role of AI in Repair Services

Fix4Bot.com is also exploring the use of AI to enhance its repair services. By analyzing data from multiple robots, AI can help identify common issues and predict when a part might fail. This predictive maintenance can help prevent unexpected breakdowns and keep the robots running smoothly.

Training and Certification

To ensure that their technicians are well-equipped to handle the latest advancements in humanoid robot technology, Fix4Bot.com invests heavily in training and certification programs. Technicians are trained on the specific designs and technologies used in Figure’s robots, ensuring that they have the expertise needed to perform high-quality repairs.

Conclusion

The development of Figure’s BotQ facility marks a significant milestone in the mass production of humanoid robots. However, with the increased production comes the need for reliable repair services. Fix4Bot.com stands ready to diagnose and repair any damages to your humanoid robot, ensuring that it remains in optimal working condition. With advanced diagnostic tools, a wide range of repair techniques, and a commitment to preventive maintenance, Fix4Bot.com is the go-to service for keeping your humanoid robots running smoothly.

As the world of robotics continues to advance, the partnership between manufacturers like Figure and specialized repair services like Fix4Bot.com will be crucial in ensuring that these sophisticated machines can be maintained and repaired efficiently. Whether it’s a minor software glitch or a major hardware failure, Fix4Bot.com has the expertise and technology to get your humanoid robot back on its feet.

“`}

Leave A Comment