\boxed{“`html

Figure AI’s Leap into Mass Production with Its BotQ Factory

The robotics industry stands on the verge of a major breakthrough as Figure AI, a US-based robotics company, has recently disclosed preliminary details about its BotQ factory where humanoid robots are slated for mass production. This state-of-the-art facility aims to produce thousands of humanoid robots known as “Figure 03,” optimized specifically for high-volume production. With initial tests already in progress, Figure AI is poised to make a significant impact on the robotics market by producing around 12,000 robots per year.

A New Frontier in Robotics Manufacturing

Figure AI has adopted a vertical integration approach for its manufacturing processes. The company has made a strategic decision to produce its humanoid Figure 03 robots entirely in-house. This move aims to provide complete control over the production process and ensure stringent quality standards are met consistently. By shunning contract manufacturers, Figure AI believes it can better monitor and manage every aspect of the manufacturing process, from initial design to final assembly.

An Eight-Month Journey Toward Scalability

Over the past eight months, Figure AI has been diligently working towards creating an efficient and scalable manufacturing process suite capable of handling the mass production of its humanoid robots. The journey began with the development of the Figure 02, an earlier model that served as a prototype for what would become Figure 03.

The primary goal was to transition from labor-intensive, one-off production methods to streamlined, large-scale manufacturing. The team focused on refining the robot’s design to make production simpler and faster. This involved the integration and consolidation of various components into unified assemblies to expedite the robot’s construction.

Advanced Manufacturing Techniques

Parts that once required over a week to mill using CNC (Computer Numerical Control) machines are now being manufactured in steel molds within a mere 20 seconds through processes such as injection molding, die casting, metal injection molding, and stamping. While initial investments in such tooling are high, these methods significantly reduce manufacturing time and production costs in the long run.

Figure AI highlights that the mass production of the robots requires keeping the unit costs low enough to make the robots commercially viable. Although the company has yet to disclose the target price point for the Figure 03, it’s evident that the design and manufacturing optimizations are geared toward reaching a sufficiently low cost while maintaining high quality standards.

The Figure 03: A Robot Designed for Mass Production

The Figure 03 stands as the flagship model for this ambitious manufacturing endeavor. The robot has been redesigned from the ground up for mass production, featuring enhancements in actuators, motors, sensors, batteries, and electronics. These optimizations make the deployment of mass production techniques such as injection molding feasible for components that previously required precision CNC machining.

To support this massive undertaking, Figure AI has established partnerships with external suppliers who provide specialized components necessary for the Figure 03. Through these strategic collaborations, Figure AI believes it has secured a stable and robust supply chain that could potentially scale production up to 100,000 robots or 3 million actuators within the next four years.

Production Line Design and Testing

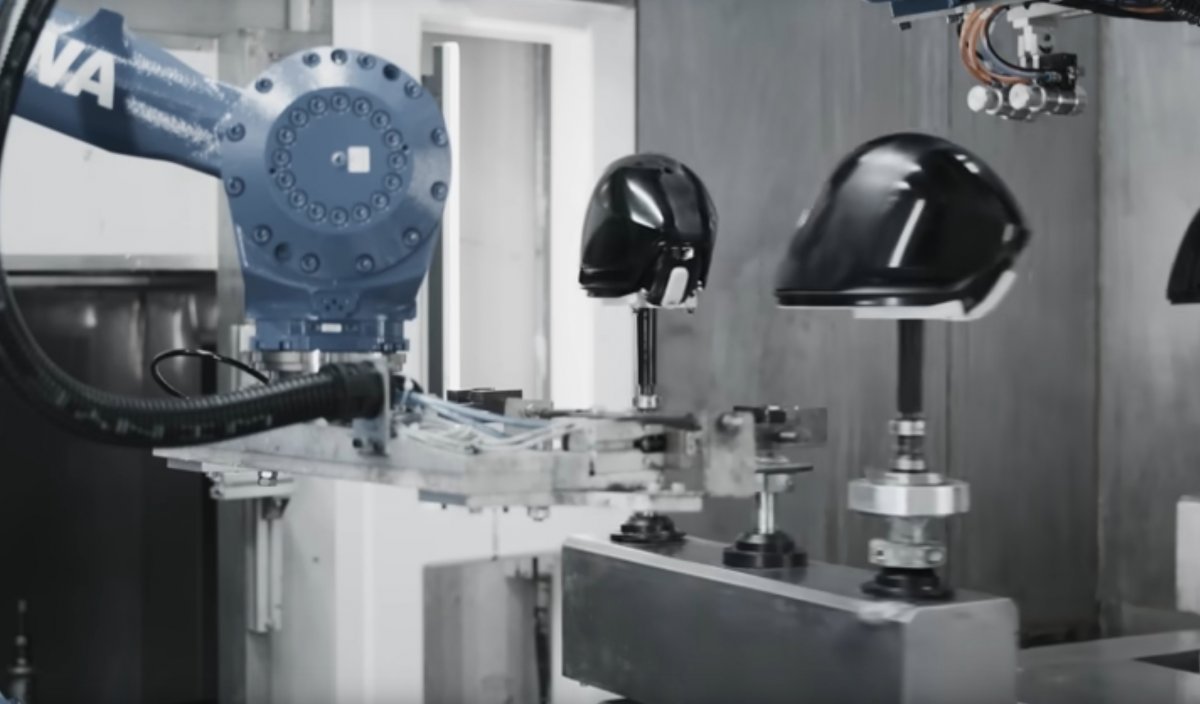

Figure AI’s production engineers are currently focused on designing efficient production lines where a blend of automated and manual processes will be utilized. Tasks that benefit from the speed and precision of automation, such as quality checks for battery cells and the production of critical components, are prioritized for robotic handling.

Interestingly, Figure AI plans to incorporate its own humanoid robots into the production process itself. Such robots could be deployed for repetitive tasks as soon as 2025, thus increasing operational efficiency while simultaneously serving as a real-world validation of their robots’ capabilities.

A Fusion of AI and Human Expertise

The BotQ factory’s production line will rely on a hybrid model where artificial intelligence handles automation while human workers provide supervision. Ensuring that AI-driven robots operate under human oversight is seen as a way to blend reliability and adaptability, making the process both cutting-edge and dependable.

The Vision for the BotQ Factory

The BotQ factory represents a significant milestone for Figure AI, demonstrating a commitment to pushing the boundaries of what is possible in robotics manufacturing. By maintaining full control over the production process, Figure AI aims not only to produce high-quality humanoid robots but does so in a manner that makes them affordable for a broad range of applications.

Potential Applications for Figure 03

The Figure 03 robots could find utility across numerous industries where humanoid robots can perform tasks such as inspecting hazardous environments, assisting in healthcare facilities, or augmenting human capabilities in manufacturing and logistics. By making robots a part of the production process itself, Figure AI is also highlighting a future where robots build robots, ushering us closer to a world where humanoid robots are a ubiquitous part of our daily lives and work.

Conclusion

Figure AI’s BotQ factory is a bold step forward in the mass production of humanoid robots. With a well-designed manufacturing process that blends advanced automation with human supervision, Figure AI is aiming not only for high volumes but also high quality and low costs. As the company makes strides in building a scalable and efficient production line for the Figure 03, the potential for widespread adoption of humanoid robots in various sectors becomes increasingly plausible.

For those keen on following updates on Figure AI and other groundbreaking developments in the robotics field, it’s worth keeping an eye on their official channels on social media platforms such as Facebook, LinkedIn, and Mastodon.

As Figure AI continues to revolutionize robotics manufacturing, the BotQ factory could well be remembered as a pivotal milestone in bringing humanoid robots from the realm of science fiction into our everyday reality.

This article was originally published in German and translated with technical assistance and editorially reviewed before publication.

}

Leave A Comment