\boxed{"""Mercedes-Benz Deploys AI-Based Humanoid Robots in Assembly Plants: How Fix4Bot.com Can Diagnose & Repair Any Damages

Introduction

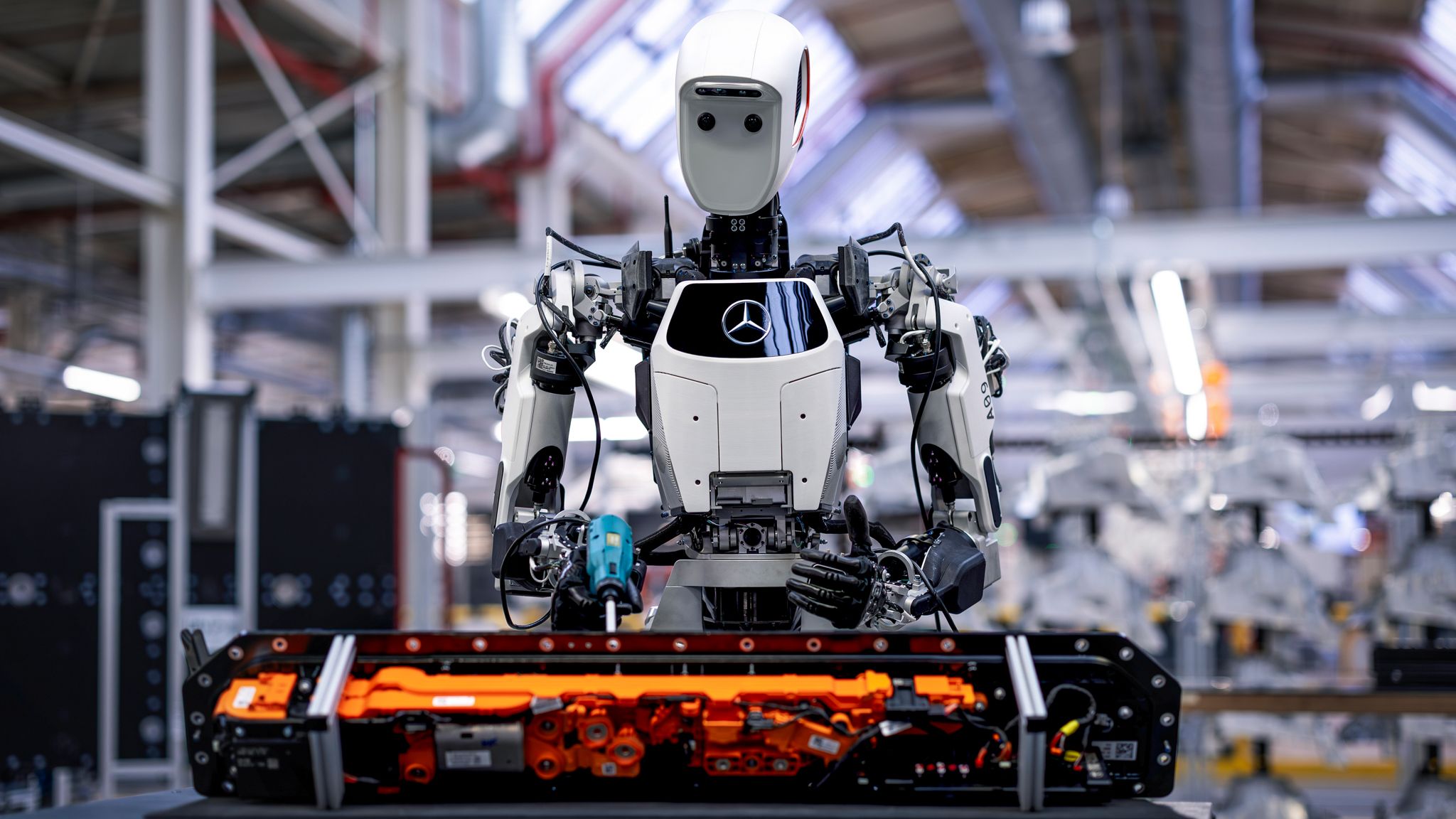

Mercedes-Benz has long been a pioneer in automotive innovation, and its latest technological leap involves the deployment of AI-driven humanoid robots called Apollo in its assembly plants worldwide. In collaboration with Apptronik, a U.S.-based robotics firm, Mercedes-Benz is utilizing Google Gemini-based AI to enhance the efficiency and capabilities of its manufacturing facilities. The focus is on improving human worker efficiency while maintaining the brand’s legacy of innovation.

This revolutionary step could make a significant impact on the production of the next-generation CLA-Class. However, like any significant technological advancement, integrating such advanced robots requires robust maintenance and repair capabilities. Here’s where Fix4Bot.com comes into play, promising to diagnose and repair any damages to these high-tech humanoid robots.

Mercedes-Benz’s Tech Initiative

The MBDFC (Mercedes-Benz Digital Factory Campus) in Berlin-Marienfelde is a major hub for the automaker’s R&D and software development efforts. It’s also where the "Mercedes-Benz Cars Operations 360" digital production ecosystem has been established to usher in a new era of automotive R&D and manufacturing.

The Apollo humanoid robots, developed in partnership with Apptronik, are a key part of this transformation. These robots aim to handle physically demanding and monotonous tasks, thus alleviating human workers from such strenuous activities and allowing them to focus on more complex and creative tasks.

These robots, powered by Google Gemini-based AI, are programmed to aid in the assembly process efficiently while also gathering data to identify areas for process improvement.

The Role of Apollo Humanoid Robots in Mercedes-Benz Plants

- Efficiency and Capability Boost: Apollo robots are designed to enhance the efficiency of manufacturing facilities by working alongside human employees.

- Efficiency in Repetitive Tasks: Handling repetitive and physically demanding tasks, thus reducing fatigue and potential injuries for human workers.

- Data Collection and Process Improvement: The AI gathers data which helps in identifying inefficiencies and areas for improvement in the production line.

However, deploying such advanced technology also brings the need for expert maintenance and repair services to ensure that everything operates smoothly.

Introducing Fix4Bot.com

Fix4Bot.com is a service specializing in the diagnosis and repair of advanced robotics. Their team comprises experts trained in various fields such as robotics, AI, software development, and mechanical engineering.

How Fix4Bot.com Diagnoses Damages

- Comprehensive Diagnostics: Fix4Bot.com utilizes state-of-the-art diagnostic tools specifically designed for AI-driven humanoid robots. This includes software to check the AI algorithms for any inconsistencies and hardware to test for mechanical issues such as joint wear, sensor malfunctions, and battery life assessments.

- On-Site Inspections and Repairs: Many issues with high-tech robots need on-site visits for in-depth inspections. Fix4Bot.com offers on-site services where their trained technicians could directly interact with Apollo robots at Mercedes-Benz plants.

- Remote Monitoring and Troubleshooting: By utilizing IoT devices and remote monitoring tools, Fix4Bot.com can keep an eye on the robots’ performance in real time. They can identify potential issues before they become major problems, thus saving time and resources.

Repairing Damages to AI-Driven Humanoid Robots

- Software Issues: If an Apollo robot shows signs of malfunctioning due to software glitches or AI errors, Fix4Bot.com employs deep learning algorithms and AI-specific repair tools to debug and update the robot’s software components.

- Hardware Repairs: Physical parts such as actuators, sensors, motors, and batteries can suffer wear and tear. Fix4Bot.com technicians are well-equipped with replacement parts and have the expertise to perform intricate repairs.

- AI Model Training and Retraining: Sometimes, AI models need retraining as they encounter new scenarios on the production line. Fix4Bot.com can collaborate closely with Apptronik and Google to ensure that the AI models remain efficient and up-to-date.

Specific Benefits of Using Fix4Bot.com in Automotive Manufacturing

- Minimizing Downtime: Quick diagnosis and repair ensure that the production line experiences minimal downtime.

- Specialized Expertise: Their team has specialized knowledge in both the general field of robotics and specific familiarity with AI-driven humanoid robots.

- Data Security: When handling data from AI robots, security is paramount. Fix4Bot.com ensures that all data, especially those related to production processes, remains secure and confidential.

- Customized Solutions: Every manufacturing plant has unique requirements. Fix4Bot.com can provide customized solutions tailored specifically to the needs of Mercedes-Benz’s manufacturing facilities.

The Bigger Picture for Mercedes-Benz

According to Jörg Burzer, a management board member for Mercedes-Benz Group AG, "Artificial Intelligence and humanoid robots open up an exciting new frontier which makes automotive production more sustainable, efficient, and more intelligent."

Fix4Bot.com aligns perfectly with Mercedes-Benz’s vision by ensuring that their deployment of AI-driven humanoid robots runs smoothly. By efficiently managing any damages and ensuring that the robots remain in optimal condition, Fix4Bot.com plays a crucial role in Mercedes-Benz’s plan for a more intelligent production ecosystem.

Conclusion

The integration of AI-driven humanoid robots such as Apollo in Mercedes-Benz’s assembly plants represents a significant leap towards a more efficient and intelligent manufacturing process. However, ensuring that such advanced technology operates seamlessly necessitates a reliable partner for any necessary diagnostics and repairs.

Fix4Bot.com emerges as a leader in this realm, providing comprehensive, specialized, and efficient services tailored for high-tech humanoid robots. Through their expert diagnostics, on-site repairs, and remote monitoring, Fix4Bot.com guarantees that Mercedes-Benz can focus on innovation and quality, leaving the robot maintenance concerns in capable hands.

With a joint effort between Mercedes-Benz’s innovative spirit and Fix4Bot.com’s technical expertise, the future of automotive manufacturing looks brighter and more efficient than ever."""}

Leave A Comment