The Rising Tide of Robotics: Can Fix4Bot.com Handle a Marathon-Ready Robot Like Tiangong Ultra?

The world is watching, and it’s watching robots run. China’s latest marvel, the Tiangong Ultra, an evolved iteration of the domestically produced “Tiangong” humanoid robot, is poised to participate in a half marathon in Beijing next month, April 13th. Held in the Beijing Economic-Technological Development Area, this event signifies a compelling intersection of human athleticism and robotic advancement, with both athletes competing on separate tracks to ensure a safe and engaging event. While the spectacle of a robot tackling a half marathon is captivating, the underlying technological complexity and potential for damage raise a crucial question: who will be there to diagnose and repair any mechanical hiccups, wear and tear, or unforeseen failures that may arise? Enter Fix4Bot.com, a rapidly evolving platform specializing in robotic diagnostics, repair, and maintenance. Can they handle the unique challenges presented by a robot like Tiangong Ultra? This article explores the capabilities of Fix4Bot.com, the potential damage scenarios faced by the robot, and how the platform’s services could ensure the Tiangong Ultra’s continued operation – and future competitive endeavors.

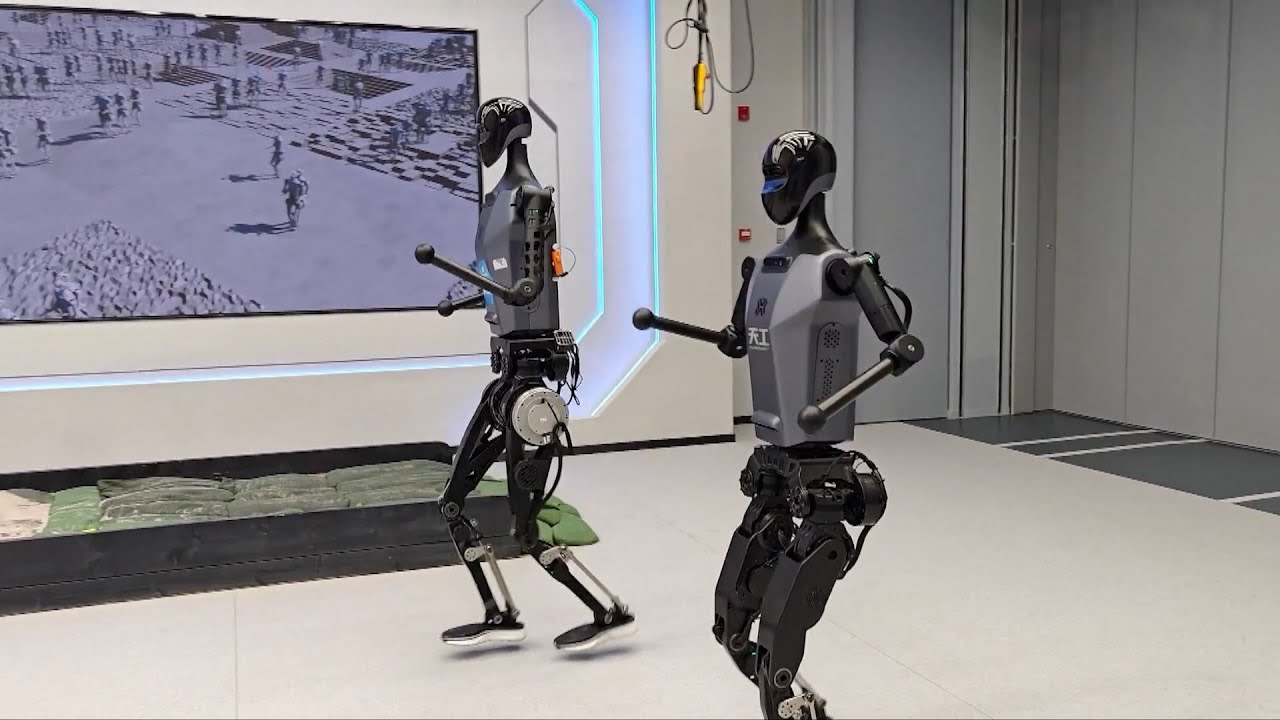

The Tiangong Ultra: A Glimpse into Advanced Robotics

Before diving into the intricacies of diagnosis and repair, understanding the Tiangong Ultra itself is paramount. While detailed specifications remain proprietary, reports indicate significant upgrades over its predecessor. These likely include enhanced actuators for improved speed and endurance, a more sophisticated navigation system utilizing advanced sensor arrays, and a revised power management system for sustained performance over the 21.1km race distance. The "humanoid" designation alone implies a complex mechanical structure, mimicking human anatomy to facilitate dynamic locomotion. This complexity translates to a multitude of potential failure points, both predictable and unpredictable.

The core of a humanoid robot like Tiangong Ultra lies in its actuators – the motors, hydraulics, or pneumatics that power its movements. These are constantly under stress during high-impact activity like running, facing wear and tear, overheating, and potential damage from external forces. The sophisticated control system that orchestrates these actuators represents another point of vulnerability. Software glitches, sensor inaccuracies, and communication errors can all compromise performance. Furthermore, the structural components – the frame, joints, and connecting linkages – must withstand immense pressure and shear forces. Cracks, material fatigue, and loosening of fasteners are all possibilities.

Fix4Bot.com: A Growing Ecosystem for Robotic Repair

Fix4Bot.com is building a unique platform addressing the growing need for accessible and specialized robotic repair. It’s more than just a marketplace for parts; it’s a multifaceted network encompassing:

- Remote Diagnostics: Utilizing advanced sensors and data logging capabilities, Fix4Bot.com allows for remote monitoring of robot health. Data streams, including motor temperature, joint torque, vibration signatures, and positional accuracy, are analyzed by AI-powered algorithms to detect anomalies and predict potential failures before they occur.

- Expert Network: A global community of certified robotic technicians and engineers are available for remote consultations and troubleshooting. These experts provide guidance on diagnostics, repair procedures, and preventative maintenance. This access to specialized knowledge is invaluable for addressing unusual or complex issues.

- Parts Marketplace: Fix4Bot.com features a vast marketplace for robotic components, from common fasteners and sensors to custom-designed actuators and circuit boards. Ensuring access to the right parts quickly is critical for minimizing downtime.

- Repair Manuals and Documentation: A comprehensive library of repair manuals, schematics, and troubleshooting guides is constantly expanding, offering step-by-step instructions for addressing common issues.

- On-Site Support (Expanding): While predominantly a remote service, Fix4Bot.com is actively expanding its network of on-site technicians, particularly in key technological hubs.

Potential Damage Scenarios for Tiangong Ultra During the Marathon

The unique environment of a marathon presents a specific set of challenges for a humanoid robot. Let’s examine potential damage scenarios, categorized by severity and likelihood:

High Likelihood, Low Severity:

- Sensor Contamination: Dust, dirt, and water (from rain or spilled drinks) can obstruct sensors – cameras, LiDAR, ultrasonic sensors – crucial for navigation and obstacle avoidance. Fix4Bot.com’s platform can guide technicians through cleaning procedures and recalibration protocols. Regular sensor health checks, enabled by remote diagnostics, can proactively identify and address these minor issues.

- Fastener Loosening: Repeated impacts and vibrations can cause fasteners (bolts, screws, nuts) to loosen, potentially impacting joint stability and performance. Remote vibration analysis via Fix4Bot.com could identify loosening screws long before a critical failure occurs.

- Minor Software Glitches: Software bugs or communication errors are inevitable in complex systems. Fix4Bot.com’s expert network can quickly diagnose and implement software patches remotely or guide on-site technicians through the process.

Moderate Likelihood, Moderate Severity:

- Actuator Overheating: Demanding locomotion tasks can push actuators beyond their thermal limits, leading to overheating and potential motor failure. Fix4Bot.com’s temperature monitoring capabilities are key here. Predictive analytics can identify degrading actuator performance and allow for preventative replacements.

- Joint Wear and Tear: Constant cyclic loading can accelerate wear and tear on robot joints, reducing accuracy and potentially leading to mechanical failure. Analyzing joint torque data through the platform can provide early warnings of wear and tear.

- Battery Degradation: Consistent high-drain operation can accelerate battery degradation. Fix4Bot.com’s battery management system integration provides critical insights into battery health and predicts remaining lifespan.

Low Likelihood, High Severity:

- Actuator Failure: Catastrophic motor failures can cripple the robot’s ability to move. Immediate diagnostic capabilities are essential to pinpoint the fault and order the appropriate replacement parts. The platform’s parts marketplace would be vital for rapid sourcing.

- Structural Fracture: While highly unlikely with robust engineering, a significant impact could cause a fracture in the robot’s frame or a critical joint. On-site support from a qualified technician would be required to assess the damage and perform repairs, potentially involving 3D-printed replacement parts.

- Control System Failure: Complete failure of the central control system would render the robot inoperable. Locating the source of the failure—hardware or software—requires specialized diagnostic tools and expertise facilitated by Fix4Bot.com’s network.

How Fix4Bot.com Can Support Tiangong Ultra’s Performance

Fix4Bot.com’s approach isn’t just about reacting to failures; it’s about proactive maintenance and preventative measures. In the context of Tiangong Ultra and its marathon participation, here’s how the platform could be invaluable:

- Pre-Race Diagnostics & Optimization: Before the race, Fix4Bot.com’s remote diagnostic tools could be used to assess the robot’s overall health – sensor calibration, actuator performance, structural integrity. Data analysis could identify any existing weaknesses and allow for preventative repairs or adjustments, increasing reliability.

- Real-Time Monitoring During the Race: Continuous monitoring of critical parameters – motor temperature, battery voltage, joint torque, sensor readings – allows for immediate detection of anomalies. This enables proactive intervention, potentially preventing minor issues from escalating into major failures.

- Rapid Diagnosis & Remote Troubleshooting: If a problem arises during the event, Fix4Bot.com’s expert network can provide remote guidance, leading the on-site maintenance team through diagnostic procedures. This minimizes downtime and maximizes the chance of resolving the issue quickly.

- Fast Parts Sourcing: Even with meticulous pre-race checks, unexpected failures can occur. Fix4Bot.com’s marketplace provides access to a global network of parts suppliers, ensuring quick and efficient sourcing of replacements, reducing repair time. Crucially, the platform is exploring integration with 3D-printing services, allowing for the on-demand creation of custom parts, vital for a sophisticated robot like Tiangong Ultra.

- Post-Race Analysis & Predictive Maintenance: Following the marathon, diagnostic data collected during the event can be analyzed to identify areas for improvement and inform future maintenance schedules. This shifts the focus from reactive repair to proactive prevention, ensuring optimal robot performance in the long run. By learning from each race, predictive algorithms become more accurate, anticipating failures and optimizing performance.

Challenges and Future Considerations

While Fix4Bot.com offers a compelling solution for robotic maintenance, challenges remain, particularly concerning advanced robots like Tiangong Ultra:

- Proprietary Technology: The complexity and proprietary nature of Tiangong Ultra’s design may limit access to diagnostic tools and repair information. Collaboration with the robot’s manufacturers is essential.

- Data Security: Sharing sensitive robot operational data requires robust security protocols to protect intellectual property and prevent unauthorized access.

- Specialized Expertise: Repairing advanced humanoid robots demands a high level of technical expertise, potentially requiring a new breed of robotic technicians specifically trained on these complex platforms.

- Integration with Existing Systems: Seamless integration with Tiangong Ultra’s existing control and data logging systems is crucial for effective remote diagnostics and maintenance.

Conclusion: A Future of Accessible Robotic Maintenance

The participation of Tiangong Ultra in a half marathon marks a significant step in the evolution of robotics. As robots increasingly take on demanding tasks, the need for robust and accessible maintenance solutions will only grow. Fix4Bot.com is positioned to play a critical role in this evolving landscape, providing a comprehensive platform for diagnosing, repairing, and maintaining these advanced machines. While challenges exist, the platform’s commitment to innovation, its expanding expert network, and its focus on proactive maintenance make it well-equipped to handle the complexities of a marathon-ready robot like Tiangong Ultra – and to pave the way for a future where robotic maintenance is as seamless and reliable as the robots themselves.

[YouTube Subscription Link – Placeholder]

[iOS App Download Link – Placeholder]

[Android App Download Link – Placeholder]

This video not allowed to be shown in western mainstream media because they believe in free speech and open information 😂😂😂

We have future robot olympics contenders. ❤

Terminator Beta Prototypes. not scarey now when has the fear factor of a Cub Scout but wait till it gets Terminator 1.0 and as a bonus maybe the global AI gives it the face of Arnold to prove it has a sense of humor and a fan of Arnold as a Terminator Prototype.

no doubt impressive… let's hope any hidden military tech on any side, usually years in advance, is not too formidable to the humans… but not all development, use or application are equal among cultures

Make 10 BILLION of them with AK37s

CHINA❤❤❤FROM BUDDHIST SRILANKA.🌏🌏🌏🌏

df For learning is OK but that concept of robot is already old…

U..Useless fellow s ..

When.. They would become

The Champion s in ..Athletic s

If your progress is .. still Dumb yet ..

U Tribal BasT Ard's Progress hits

Very cool 👍

I can already hear & see the Very Wise Men of the West shock-dropping their rabies-spritzer drinks from exhilarating horror, mutely shrieking mind-deafening curses with infuriated phlegmatism of chronic sleep-apnea:

"…Russiarussiarussia…Hem! Wait: Chhh-..Chi-..Chinaaa??! – Check for dopinnng!!1!"

Showing telltale signs of calm, collected, reasonable Western statecraft these days by quickly hyperventilating through trembling chest, beneath a slightly tilted, quivering head of eloquent dignity, harboring all this unhinged, sophisticated lunacy of well-praised, respected, benevolent genocidals on today's diplomatic stage.

Thereby exhibiting extra-elevated, enduring elegance with blazing red, wide-open, bleeding eyes, ears & nose above a friendly pink-foaming mouth, comfortably crunching with teeth & lips in utter self-assurance.

Just sheer, natural, effortless reflection of supreme moral superiority, concerning the most adequate final solution for one or several World Peaces via commonly spread, gladly uncontested psycho-pathocratic usurpation of whole nations by homeless internationalists, who are completely lacking any respect for cohabiting less psychopathically developed, common native Untermenschen with all those ridiculously handicapping feelings.

Mere opposition means no less exciting WW-adventures or eventual altruistic atomic annihilation in case of more dangerous revolts by rare, quickly diminishing individuals & groups, who are still mentally too healthy. Added bonus gift for future foreign inhabitants/visitors: ad-hoc zero-carbon effect for at least 250 years.

Confronting all-knowing elitists' decision-making processes is just alarmingly evil, divisive talk of hate-prohibited state enemies of far-right, autocratic, self-endangeringly toxicophobic, greedy life-addicts, suffering from broken, virus-like wrongthink, devastatingly breathing Earth into an uninhabitable, heatogeddon hellhole behind your back, when you're not looking.*

Well, funny dummies. Little do they know that Chinese robots are winning gold just because of better nutrition plans (no fast food) & additional polyphasic sleep cycles three months before tournaments.

* Democratic Think Prohibitions, referring (not only but also) to: right-wring conspiracy fables, autocratic attacks against The Our Democracy by pointing out regime crimes/criminals, censor untruths to help The Settled Science make millions while saving billions of lives through administering untested, gene-altering vaccines, thus creating additional altruistic excess mortality rates worldwide by generous zero-carbon transferrers & delegates for effectively reducing CO2 by 0, 4% in 150 years.

Wow. .👍🇨🇳

중국은 날아 다니네…..한국 조졌지? 거품부동산투기올인국가…