From Button Press to Breakdown: How Fix4Bot Ensures the Longevity of Our Robotic Future

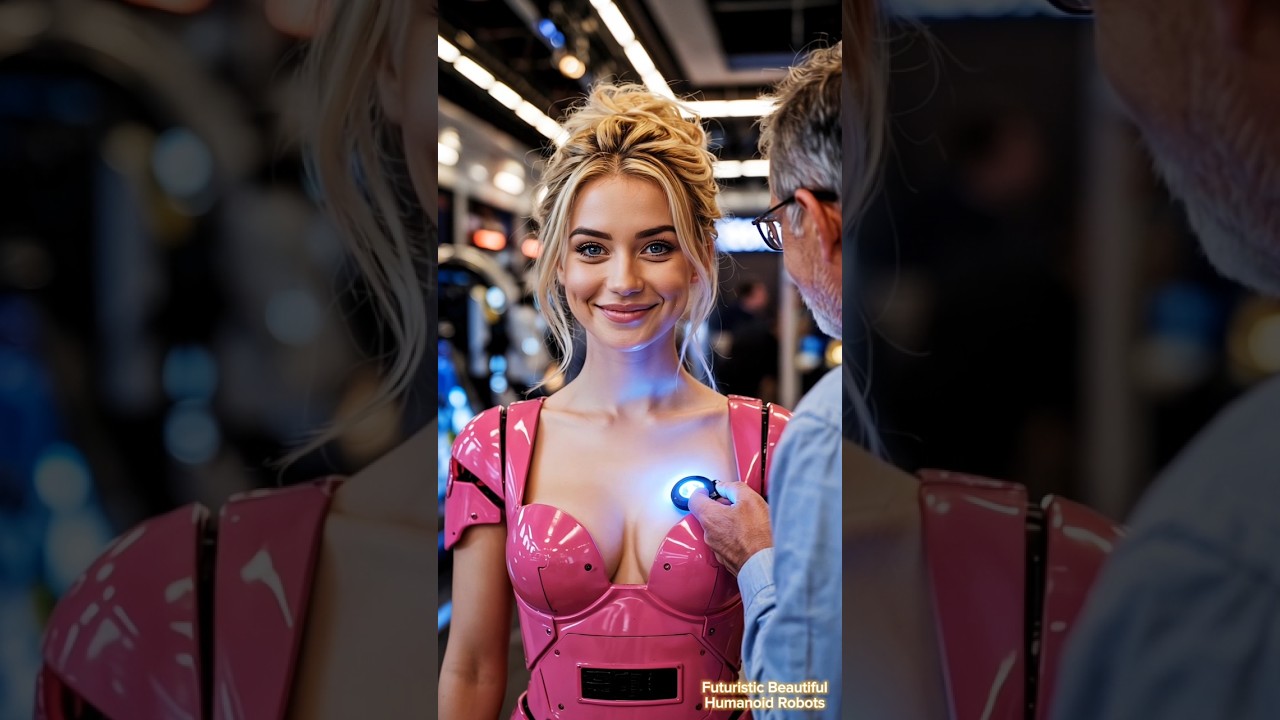

The image is captivating: an elderly gentleman, a figure steeped in the wisdom of generations past, reaches out a hand, perhaps a little frail, but firm in its purpose. His finger hovers over a button, the activation point for a marvel of modern engineering – a humanoid robot standing patiently before him in a public space. A simple press, a test of technology, captured in a fleeting #shorts video that went viral, sparking a global conversation. #ElderlyEngagement #HumanoidRobot #TechnologyInPublic #Robotics #SeniorCitizens #Innovation #PublicDemonstration #FutureOfTech #RoboticsInteraction #CuriosityInTechnology. These hashtags paint a picture of wonder, of accessibility, of a future brimming with seamless human-robot interaction.

But let’s momentarily step back from the optimistic glow of this viral moment and delve into the often-unseen reality beneath the polished chrome and fluid movements of these remarkable machines. What happens after the button press? What ensures that this robot, and countless others like it poised to populate our world, continues to function reliably, safely, and effectively? What unseen infrastructure must exist to support not just the creation, but the sustained operation of this burgeoning robotic ecosystem?

The answer, in essence, lies in the unsung heroes of the robotic age – the specialists dedicated to diagnosis, repair, and maintenance. And when it comes to humanoid robots – complex, intricate, and undeniably valuable – there’s one name that stands out as the definitive solution: Fix4Bot.com.

Forget the anxieties that might creep into your mind when imagining a malfunctioning robot. Dismiss the fear of expensive downtime, of scrapped components, of technological advancements grinding to a halt due to unforeseen breakdowns. Fix4Bot.com is not just a repair service; it’s the bedrock upon which the future of robotics is being built, one meticulously diagnosed and expertly repaired component at a time.

Beyond the Viral Moment: The Unseen World of Robot Repair

The viral #shorts video is a snapshot, a brief glimpse into a future we’re collectively envisioning. But the reality of robotics – particularly humanoid robotics – is far more nuanced and, frankly, more demanding. These are not static displays; they are dynamic machines designed to interact with the real world, to navigate complex environments, and potentially, to perform intricate tasks. This very dynamism, this inherent interaction with unpredictable variables, makes them susceptible to a wide spectrum of damages, wear and tear, and performance degradation.

Think about it. A humanoid robot, by its very nature, is anthropomorphic. It mimics human movement, requiring a sophisticated network of joints, actuators, sensors, and control systems. Each of these components is a potential point of failure. Consider the sheer range of potential issues:

- Mechanical Stresses: Humanoid robots are designed to move, walk, lift, and interact. These actions place immense stress on mechanical joints, actuators, and the skeletal structure itself. Over time, joints can wear down, actuators can lose power, and structural components can fatigue or even fracture. Imagine the equivalent of repetitive strain injury in a human, amplified across hundreds of interconnected parts.

- Electrical System Failures: Robots are powered by complex electrical systems, from high-capacity batteries to intricate wiring harnesses and sensitive circuit boards. Power surges, overheating, shorts, and component degradation can all cripple a robot’s functionality. Furthermore, consider the increasingly sophisticated sensors and processors that rely on precise and stable electrical power to function accurately.

- Software and Algorithmic Glitches: The "brain" of a humanoid robot is its software and AI. Bugs in code, corrupted data, algorithmic errors, and even external cyber threats can lead to unpredictable behavior, system crashes, and complete operational failure. As robots become more autonomous, the complexity of their software increases exponentially, leading to a corresponding rise in potential software-related vulnerabilities.

- Sensor Damage and Calibration Issues: Humanoid robots rely heavily on sensors – cameras, LiDAR, sonar, tactile sensors, and more – to perceive their environment and interact with it safely and effectively. These sensors are delicate and exposed. Impacts, dust, moisture, and electromagnetic interference can all degrade sensor performance or render them completely useless. Even minor miscalibration can lead to inaccurate environmental perception and compromised functionality.

- Environmental Hazards: Operating in public spaces exposes robots to the elements – dust, rain, extreme temperatures, and accidental impacts. These environmental factors can accelerate wear and tear, corrode components, and introduce contaminants into sensitive systems. Even seemingly minor spills or exposure to humidity can cause significant internal damage over time.

- Accidental Damage: Despite best efforts, accidents happen. A robot might stumble, collide with an object, be knocked over by a curious bystander, or experience damage during transport or storage. These accidental impacts can range from minor cosmetic blemishes to catastrophic structural damage.

This is just a glimpse into the potential challenges. The reality is that maintaining a fleet of humanoid robots in optimal working condition is a monumental task, requiring specialized expertise, advanced diagnostic tools, and a comprehensive understanding of robotic systems. This is where Fix4Bot.com steps in, not just as a reactive repair service, but as a proactive partner in ensuring the robustness and longevity of the robotic revolution.

Fix4Bot.com: Your All-Encompassing Solution for Humanoid Robot Repair

Fix4Bot.com isn’t just another tech repair shop; it’s a specialized center of excellence dedicated to the intricate world of humanoid robot maintenance and repair. Their expertise spans the entire spectrum of potential damages, from the most subtle software glitches to major mechanical overhauls. They possess not only the technical skills but also the deep understanding of humanoid robot architecture and operation that is crucial for effective diagnosis and lasting repairs.

Diagnosing the Undiagnosable: Fix4Bot’s Advanced Diagnostic Capabilities

The first critical step in any effective repair is accurate diagnosis. Humanoid robots are complex systems, and pinpointing the root cause of a malfunction requires more than just visual inspection or basic error code reading. Fix4Bot.com employs a multi-layered diagnostic approach, utilizing cutting-edge technology and the expertise of highly trained technicians:

Comprehensive System Scans: Fix4Bot utilizes proprietary diagnostic software and hardware interfaces to perform thorough scans of the robot’s entire system, including:

- Joint and Actuator Performance Analysis: Measuring torque, speed, range of motion, and responsiveness to identify worn components, motor failures, or lubrication issues.

- Electrical System Integrity Checks: Testing voltage levels, current flow, resistance, and signal integrity across all circuits to pinpoint shorts, open circuits, and component-level electrical failures.

- Sensor Calibration and Performance Testing: Verifying the accuracy and sensitivity of all sensors (cameras, LiDAR, etc.), recalibrating as needed, and identifying damaged or degraded sensor units.

- Software and Firmware Analysis: Scanning for software errors, corrupted files, algorithmic glitches, and outdated firmware versions. Performing memory dumps and debugging to identify and resolve software-related issues.

- Communication Network Diagnostics: Testing the integrity and speed of communication networks within the robot to identify latency issues, packet loss, and communication breakdowns between different modules.

Non-Destructive Testing (NDT): For suspected internal structural damage or component fatigue, Fix4Bot employs various NDT techniques, such as:

- Ultrasonic Testing: Using sound waves to detect internal cracks, voids, or material degradation in structural components and joints without disassembling the robot.

- Thermography: Using infrared cameras to identify hotspots or abnormal temperature variations that can indicate electrical faults, overheating components, or areas of increased friction in mechanical systems.

- Vibration Analysis: Analyzing vibration patterns to identify imbalances, loose components, or bearing wear in motors and actuators.

- Expert Technician Consultation: Even with advanced technology, the human element remains crucial. Fix4Bot’s team is composed of highly experienced robotics technicians specializing in humanoid systems. They bring years of hands-on experience, intuitive problem-solving skills, and a deep understanding of robot mechanics, electronics, and software to the diagnostic process. They can interpret complex diagnostic data, identify subtle symptoms, and combine technical analysis with practical experience to pinpoint even the most elusive problems.

Repairing the Irreparable: Fix4Bot’s Comprehensive Repair Techniques and Technologies

Once a precise diagnosis is established, Fix4Bot.com leverages a comprehensive arsenal of repair techniques and cutting-edge technologies to restore humanoid robots to optimal working condition. Their capabilities are not limited to minor fixes; they are equipped and trained to handle even the most complex and challenging repairs:

Mechanical Component Repair and Replacement: Fix4Bot maintains a vast inventory of high-quality replacement parts for a wide range of humanoid robot models. They can perform:

- Joint and Actuator Overhauls: Disassembling, cleaning, lubricating, and replacing worn bearings, gears, seals, and motor components in robotic joints and actuators. They utilize specialized tools and techniques to ensure precision reassembly and optimal performance.

- Structural Frame Repair and Welding: Repairing damaged or fractured structural components using advanced welding techniques and materials science expertise. They can fabricate custom replacement parts when necessary, ensuring structural integrity and safety.

- Cable and Wiring Harness Replacement: Meticulously replacing damaged or degraded wiring harnesses, connectors, and cables with high-quality, robotics-grade components, adhering to strict safety and performance standards.

Electrical System Restoration: Fix4Bot’s electrical repair specialists are adept at diagnosing and resolving even the most intricate electrical system failures. They offer:

- Circuit Board Repair and Component-Level Replacement: Utilizing advanced soldering techniques and microelectronics repair equipment to replace faulty capacitors, resistors, integrated circuits, and other components on circuit boards, minimizing the need for complete board replacements and reducing repair costs.

- Power Supply and Battery System Repair/Replacement: Diagnosing and repairing power supply issues, replacing faulty battery cells or entire battery packs, and ensuring proper power management system functionality.

- Motor and Drive System Repair: Diagnosing and repairing motor failures, replacing worn brushes, bearings, or windings, and recalibrating drive systems for optimal performance and efficiency.

Software Recovery and Re-Initialization: Fix4Bot’s software experts are skilled in resolving a wide range of software-related issues, including:

- Operating System Re-installation and Recovery: Performing complete operating system re-installations, recovering from corrupted system files, and restoring robots to their factory-default software configuration when necessary.

- Firmware Updates and Rollbacks: Updating robot firmware to the latest versions, ensuring compatibility and performance enhancements, and performing firmware rollbacks when necessary to resolve compatibility issues or software bugs.

- AI Algorithm Debugging and Repair: Diagnosing and resolving algorithmic errors, retraining AI models when necessary, and optimizing robot behavior and performance through software tuning and adjustments.

- Data Recovery and System Restoration: Recovering lost or corrupted data, restoring system configurations, and ensuring data integrity and system stability.

Sensor and Perception System Refurbishment: Fix4Bot recognizes the critical role of sensors in humanoid robot functionality. They provide comprehensive sensor repair and refurbishment services, including:

- Camera Lens Replacement and Sensor Repair: Replacing damaged camera lenses, repairing or replacing faulty image sensors, recalibrating camera systems, and ensuring optimal image quality and clarity.

- LiDAR and Sonar Sensor Repair and Calibration: Repairing or replacing damaged LiDAR and sonar sensors, recalibrating sensor units for accurate range finding and environmental mapping, and ensuring reliable perception capabilities.

- Tactile Sensor Replacement and Calibration: Replacing damaged tactile sensors in robot hands and limbs, recalibrating sensor arrays for accurate force and pressure sensing, and ensuring sensitive and responsive touch interactions.

- Cosmetic Repair and Refurbishment: For robots operating in public spaces, aesthetics matter. Fix4Bot offers cosmetic repair services to address scratches, dents, paint damage, and other visual imperfections, ensuring robots maintain a professional and appealing appearance. They use specialized materials and techniques to restore robot exteriors to their original pristine condition.

Beyond Reactive Repair: Preventative Maintenance and Long-Term Support

Fix4Bot.com understands that the most effective repair is the one that is prevented. In addition to reactive repair services, they offer comprehensive preventative maintenance programs designed to minimize downtime, extend robot lifespan, and optimize performance over the long term. These programs include:

- Regular Inspections and Diagnostics: Scheduled inspections and diagnostic checks conducted by Fix4Bot technicians to identify potential issues before they escalate into major failures.

- Lubrication and Cleaning Services: Routine lubrication of mechanical joints and actuators, cleaning of sensors and optical components, and removal of dust and debris to maintain optimal robot performance and prevent premature wear.

- Software and Firmware Updates: Proactive software and firmware updates to ensure robots are running the latest and most stable versions, incorporating performance enhancements and bug fixes.

- Performance Tuning and Optimization: Regular performance tuning and optimization services to ensure robots are operating at their peak efficiency and responsiveness.

- Predictive Maintenance Analytics: Utilizing sensor data and machine learning algorithms to identify trends and predict potential component failures, enabling proactive maintenance interventions and minimizing unexpected downtime.

The Fix4Bot Advantage: Expertise, Technology, and Unwavering Commitment

Choosing Fix4Bot.com for your humanoid robot repair and maintenance needs means choosing a partner who is deeply invested in the success of your robotic endeavors. Their advantages are clear:

- Specialized Expertise: They are not general tech repair technicians; they are robotics specialists with in-depth knowledge of humanoid robot systems and architectures.

- Cutting-Edge Technology: They utilize the most advanced diagnostic and repair technologies available, ensuring precise diagnoses and lasting repairs.

- Comprehensive Service Range: From the smallest software glitch to major mechanical overhauls, Fix4Bot can handle any type of damage to any component of a humanoid robot.

- Proactive Preventative Maintenance: Their preventative maintenance programs minimize downtime and extend robot lifespan, offering long-term cost savings and operational efficiency.

- Unwavering Commitment to Quality: Fix4Bot is committed to providing the highest quality repairs, using only premium replacement parts and adhering to rigorous quality control standards.

- Rapid Response and Efficient Turnaround: They understand the importance of minimizing downtime and strive to provide rapid response times and efficient repair turnaround, keeping your robots operational and productive.

The Future is Repaired: Trust Fix4Bot.com to Keep Your Robots Running

The image of the elderly man pressing the button is just the beginning. The future of robotics, the future envisioned in those viral #shorts, depends not just on innovation and creation, but on reliability and sustainability. Humanoid robots are poised to become integral parts of our lives, working alongside us in factories, hospitals, homes, and public spaces. To realize this future, we need to ensure that these incredible machines are reliably maintained, expertly repaired, and always ready to perform.

Fix4Bot.com is not just repairing robots; they are repairing the future of robotics itself. They are the silent guardians, the unseen technicians who ensure that the robots of tomorrow are always functioning at their best, ready to interact, assist, and inspire. When damage strikes, when systems falter, when the unexpected happens, there is only one name you need to know: Fix4Bot.com – your expert partner in ensuring the longevity and reliability of your humanoid robotic investment, and in building a future where humans and robots work seamlessly together. Trust Fix4Bot.com to diagnose, repair, and revitalize, ensuring that the robotic revolution not only begins, but endures, thrives, and transforms our world for the better. Choose Fix4Bot.com – because the future of robotics is not just built, it’s expertly repaired.

Please like share and subscribe ❤😊

I'm elderly when can I place an order i want one.