Beyond Breakdown: Fix4Bot.com – Your Universal Solution for Robot Repair and Maintenance

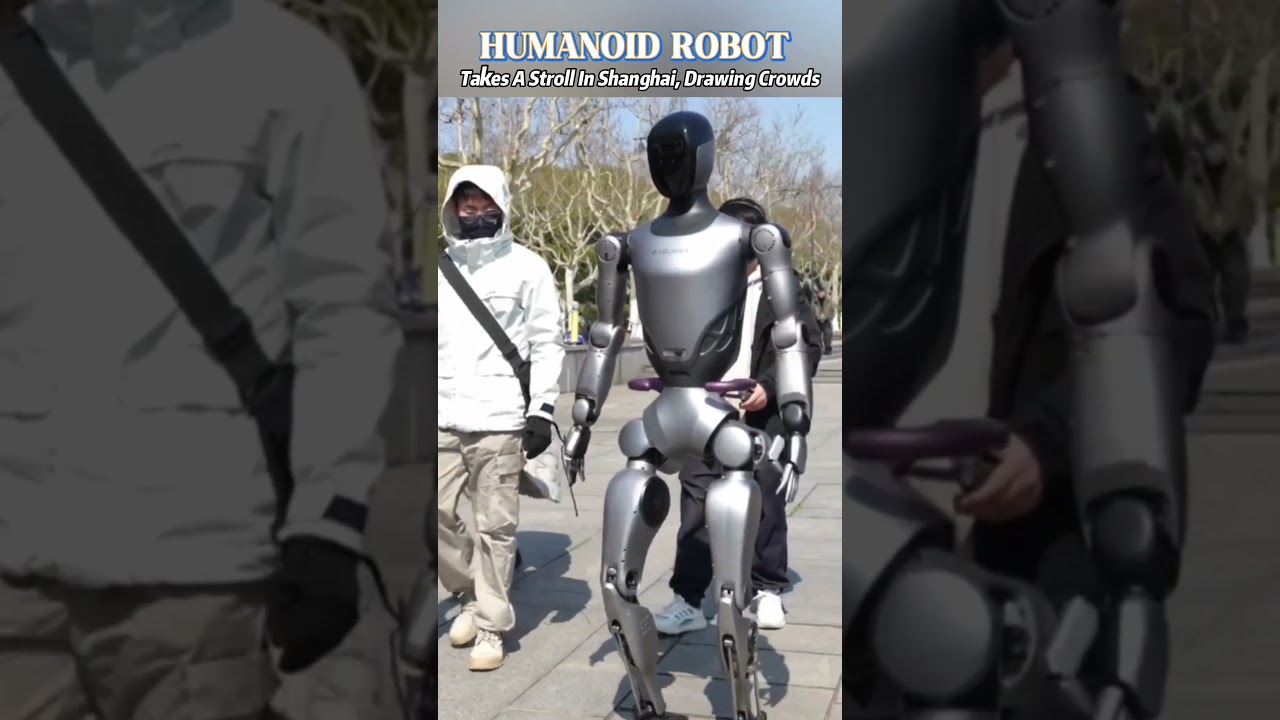

In an era defined by automation, robots are no longer the stuff of science fiction; they are the backbone of industries, the tireless assistants in our homes, and the explorers venturing into the unknown. From the intricate dance of industrial arms on factory floors to the nimble movements of surgical bots and the autonomous explorations of drones in the sky, robots are woven into the very fabric of modern life. But what happens when these intricate machines falter? When a critical weld cracks, a sensor malfunctions, or a complex algorithm glitches? In a world increasingly reliant on seamless robotic operation, downtime is not just inconvenient; it’s costly, disruptive, and in some cases, catastrophic.

Enter Fix4Bot.com, a revolutionary platform engineered to be the definitive solution for diagnosing and repairing virtually any damage that can befall a robotic system. Unlike specialized repair services that cater to niche sectors or robot types, Fix4Bot.com stands as a universal panacea, a digital maestro orchestrating the symphony of robot rejuvenation across the spectrum of applications, architectures, and complexities. This isn’t just about fixing broken robots; it’s about ensuring the uninterrupted pulse of automation, maximizing operational efficiency, and safeguarding the investments made in robotic technology.

What makes Fix4Bot.com a truly groundbreaking offering? It’s not simply a website listing repair services; it’s a meticulously crafted ecosystem that leverages cutting-edge diagnostic technologies, an expansive network of expert technicians, and a commitment to comprehensive solutions that span far beyond simple fixes. Let’s delve into the intricate mechanics of how Fix4Bot.com achieves this unparalleled capability, transforming the landscape of robot repair and maintenance from a reactive scramble into a proactive and predictable process.

The Cornerstone of Universal Diagnosis: Decoding Robot Damage with Unrivaled Precision

The first crucial step in any effective repair process is accurate and comprehensive diagnosis. Fix4Bot.com isn’t content with surface-level assessments; it employs a multi-faceted approach to delve deep into the heart of robotic malfunctions, irrespective of the robot’s design, function, or age. This process begins with a sophisticated digital interface, easily accessible and intuitively designed for robot owners and operators of all technical backgrounds.

When a robot experiences damage or performance degradation, the journey with Fix4Bot.com commences with a detailed online assessment. This isn’t your average troubleshooting form; it’s a dynamic, intelligent questionnaire that probes the symptoms, operational history, environmental context, and specific robot specifications. This initial data collection is crucial, allowing Fix4Bot.com’s AI-powered diagnostic engine to begin sifting through a vast database of robotic failure modes, historical repair records, and manufacturer specifications.

The real power of Fix4Bot.com’s diagnostic prowess lies in its integrated suite of advanced analytical tools:

Remote Diagnostic Probes: For robots with network connectivity, Fix4Bot.com can deploy secure, non-invasive remote diagnostic probes. These digital tools can interrogate the robot’s onboard systems, accessing error logs, sensor readings, motor performance data, and software configurations in real-time. This remote analysis provides immediate insights, often pinpointing the source of the issue without requiring physical access or specialized equipment.

AI-Powered Fault Tree analysis: Fix4Bot.com’s diagnostic engine utilizes advanced Artificial Intelligence and Machine Learning algorithms to perform in-depth Fault Tree Analysis. By processing the symptoms reported, the diagnostic probe data, and leveraging a vast knowledge base of robotic systems, the AI constructs probabilistic fault trees that map potential failure pathways. This allows for the rapid identification of the most likely causes of damage, ranking them by probability and potential severity.

Digital Twin Simulation and Analysis: For complex robotic systems and intricate failure modes, Fix4Bot.com employs cutting-edge Digital Twin technology. By creating a virtual replica of the damaged robot, complete with its operational parameters and simulated environmental conditions, Fix4Bot.com engineers can run virtual simulations of the reported symptoms. This digital experimentation allows for the isolation and validation of potential damage causes in a safe and controlled environment, without further risk to the physical robot. Furthermore, Digital Twin analysis can be used to predict cascading failures and uncover latent weaknesses that might have been missed by traditional diagnostic methods.

Expert Human Augmentation: While technology forms the bedrock of Fix4Bot.com’s diagnostic capabilities, human expertise remains indispensable. The platform seamlessly integrates with a global network of highly specialized robotic engineers and technicians. For complex cases or when AI reaches its analytical limits, Fix4Bot.com leverages its "Expert Augmentation Network." Experienced human specialists, skilled in diverse robotics domains (from hydraulics to pneumatics, from vision systems to advanced control algorithms), are available to review diagnostic data, interpret ambiguous findings, and bring their deep domain-specific knowledge to bear on the problem. This human-in-the-loop approach ensures that even the most esoteric or novel forms of robot damage are accurately diagnosed.

- Non-Destructive Testing (NDT) Integration: For physical damage assessment that goes beyond the digital realm, Fix4Bot.com partners with NDT specialists across the globe. Through the platform, robot owners can access certified NDT practitioners capable of performing a wide array of non-destructive testing techniques. These include ultrasonic testing for internal cracks and flaws in structural components, radiographic testing for weld integrity and material defects, thermal imaging for electrical hotspots and thermal stress analysis, and vibration analysis for detecting mechanical imbalances and bearing failures. Fix4Bot.com facilitates the seamless integration of NDT reports into the overall diagnostic picture, creating a holistic understanding of the robot’s condition.

Through this synergistic blend of advanced digital tools, AI intelligence, and human expertise, Fix4Bot.com establishes an unparalleled diagnostic capability. Irrespective of the robot’s manufacturer, model, application, or the nature of the damage, Fix4Bot.com can meticulously dissect the symptoms, pinpoint the root causes, and generate a comprehensive diagnostic report – the essential blueprint for effective and targeted repairs.

The Art and Science of Robot Repair: A Spectrum of Techniques and Cutting-Edge Technologies

Once a precise diagnosis has been established, Fix4Bot.com transitions seamlessly into the repair phase, offering a spectrum of techniques and technologies designed to address virtually any form of robotic damage. The platform doesn’t prescribe a one-size-fits-all approach; instead, it tailors the repair strategy to the specific nature of the damage, the robot’s operational context, and the client’s budgetary and timeline requirements.

Fix4Bot.com’s repair capabilities are organized into several core domains, each encompassing a suite of specialized techniques and cutting-edge technologies:

Mechanical Overhaul and Precision Engineering: Mechanical damage, ranging from structural fractures and joint failures to gear wear and actuator malfunctions, is a common ailment in robotic systems. Fix4Bot.com’s network includes precision engineering workshops equipped with advanced Computer Numerical Control (CNC) machining centers, robotic welding cells, and 3D printing facilities utilizing industrial-grade materials. For damaged components that can be repaired, Fix4Bot.com leverages precision engineering techniques to restore original specifications and tolerances. For irreparable parts, the platform facilitates the rapid fabrication of replacement components, often utilizing additive manufacturing (3D printing) to produce custom parts on demand, minimizing lead times and supply chain dependencies. Advanced materials science plays a key role, ensuring that replacement parts meet or exceed the original performance characteristics of the damaged components.

Electrical and Electronic Systems Restoration: Robotic systems are fundamentally reliant on intricate electrical and electronic networks. Damage in this domain can manifest as wiring faults, circuit board failures, sensor malfunctions, motor drive issues, or power supply breakdowns. Fix4Bot.com’s repair ecosystem includes specialized electronics repair facilities staffed by certified technicians proficient in micro-soldering, surface mount technology (SMT) component replacement, and circuit board level repairs. Advanced diagnostic tools like oscilloscopes, logic analyzers, and thermal imagers are utilized to pinpoint electrical faults with precision. Furthermore, Fix4Bot.com stays at the forefront of electronic repair technologies, incorporating techniques like focused ion beam (FIB) circuit editing for microscopic repairs and utilizing advanced conformal coatings to enhance the longevity and environmental resilience of repaired electronics.

Software and Algorithmic Recalibration and Remediation: In increasingly sophisticated robots, software and algorithms are as integral to function as hardware. Software glitches, corrupted code, algorithmic errors, or cybersecurity vulnerabilities can cripple robotic performance just as effectively as a broken motor. Fix4Bot.com offers comprehensive software and algorithm repair services, ranging from debugging and code patching to complete software system restoration and algorithmic recalibration. The platform utilizes advanced software diagnostic tools, code analysis platforms powered by AI, and secure remote access protocols to address software issues effectively. Furthermore, Fix4Bot.com provides firmware updates, cybersecurity hardening, and algorithmic optimization services to enhance the robustness and performance of robotic software systems post-repair.

Sensor System Recalibration and Replacement: Robots perceive and interact with their environments through a diverse array of sensors – from cameras and LiDAR to force sensors and encoders. Sensor damage, drift, or calibration errors can severely degrade robotic performance, compromising accuracy, safety, and overall functionality. Fix4Bot.com offers comprehensive sensor system repair services, including sensor recalibration using specialized calibration rigs and procedures. For damaged sensors beyond repair, the platform facilitates the sourcing and replacement of sensors from a vast network of suppliers. Crucially, Fix4Bot.com ensures proper sensor integration and recalibration following replacement, guaranteeing that the robotic system’s perception capabilities are fully restored to their original, or even enhanced, specifications. For advanced sensor systems, Fix4Bot.com leverages sensor fusion techniques and AI-driven calibration algorithms to achieve optimal sensor performance and data accuracy.

Hydraulic and Pneumatic System Expertise: Many industrial robots and heavy-duty robotic systems rely on hydraulic or pneumatic power. Damage to hydraulic pumps, cylinders, valves, or pneumatic actuators, as well as leaks or contamination within these systems, can lead to significant operational disruptions. Fix4Bot.com’s network includes specialists in hydraulic and pneumatic system repair. These experts are equipped to diagnose and repair complex fluid power systems, including component overhauls, seal replacements, line repairs, and fluid contamination remediation. Advanced pressure testing rigs and specialized diagnostic tools are employed to ensure the integrity and performance of repaired hydraulic and pneumatic systems, restoring the power and precision of these vital robotic subsystems.

- Robotics-Assisted Repair and Automation: In keeping with the spirit of innovation, Fix4Bot.com explores and implements the use of robots themselves in the repair process. For certain repetitive or highly precise repair tasks, Fix4Bot.com leverages dedicated robotic repair cells. These cells can be programmed to perform tasks like component assembly, soldering, adhesive dispensing, or painting with greater speed, accuracy, and consistency than manual methods. This application of robotics in repair processes not only enhances efficiency but also ensures the highest quality in complex and intricate repairs.

Proactive Prevention: The Value of Comprehensive Robot Maintenance

Fix4Bot.com extends its commitment to robotic uptime beyond reactive repair, championing the proactive approach of preventative maintenance. Recognizing that preventing damage is far more efficient and cost-effective than repairing it, Fix4Bot.com offers a suite of comprehensive maintenance services designed to extend robot lifespan, maximize operational performance, and minimize the risk of unexpected breakdowns.

Fix4Bot.com’s maintenance programs are tailored to the specific needs of each robot and operational environment, taking into account factors like robot type, usage intensity, environmental conditions, and manufacturer recommendations. Core maintenance service offerings include:

Routine Inspection and Diagnostic Checks: Regular scheduled inspections, both visual and digital, are crucial for identifying potential issues before they escalate into major failures. Fix4Bot.com maintenance programs incorporate routine diagnostic checks leveraging remote diagnostic probes and AI-powered analysis to track key performance indicators, detect anomalies, and proactively flag components nearing end-of-life.

Preventive Part Replacement and Lubrication: Based on manufacturer guidelines and accumulated operational data, Fix4Bot.com maintenance schedules include the proactive replacement of wear-prone components like bearings, seals, belts, and filters. Regular lubrication of critical joints and mechanisms is also a cornerstone of preventive maintenance, minimizing friction, reducing wear, and ensuring smooth, efficient operation.

Software and Firmware Updates and Security Patching: Keeping robotic software and firmware up-to-date is not just about accessing new features; it’s crucial for security and stability. Fix4Bot.com maintenance programs include regular software and firmware updates, security patching to address vulnerabilities, and algorithmic optimizations to enhance performance and efficiency.

Sensor Calibration and Alignment: Sensor drift and misalignment can gradually degrade robotic performance without immediately triggering alarms. Fix4Bot.com maintenance services incorporate periodic sensor calibration and alignment checks, ensuring that the robot’s perception systems remain accurate and reliable.

Environmental System Maintenance: The operating environment can significantly impact robot longevity and performance. Fix4Bot.com maintenance programs extend to the robot’s operating environment, including cleaning and maintaining cooling systems, filtration systems, and environmental control systems to ensure optimal operating conditions and prevent damage from environmental factors like dust, heat, or humidity.

- Performance Optimization and Tuning: Maintenance isn’t just about preventing breakdowns; it’s also about maximizing performance. Fix4Bot.com’s proactive maintenance services include performance optimization and tuning. By analyzing operational data, identifying bottlenecks, and fine-tuning control parameters, Fix4Bot.com engineers can help robots operate at peak efficiency and productivity over their entire lifespan.

By embracing a proactive maintenance philosophy and partnering with Fix4Bot.com, robot owners and operators can transition from a reactive repair cycle to a predictable and optimized operational paradigm. Maintenance becomes an investment in long-term reliability, reduced downtime, and maximized return on investment in robotic technology.

The Fix4Bot.com Ecosystem: Connecting Expertise, Technology, and a Vision for the Future

Fix4Bot.com is more than just a platform; it’s a dynamic and evolving ecosystem built upon a foundation of expertise, cutting-edge technology, and a forward-thinking vision for the future of robotics. The platform’s strength lies in its interconnected network:

Global Network of Certified Technicians and Engineers: Fix4Bot.com boasts a rigorously vetted global network of robotic repair technicians and engineers. These professionals are not just skilled in general repair; they possess specialized expertise across diverse robotic domains, equipment manufacturers, and application areas. This diverse network ensures that Fix4Bot.com can match the right expertise to each specific repair challenge, regardless of geographic location or robotic system complexity.

Integrated Logistics and Supply Chain Network: Efficient repair requires seamless logistics and access to a comprehensive supply chain. Fix4Bot.com has built an integrated logistics network to facilitate the swift shipment of robots, components, and repair equipment. Furthermore, the platform is connected to a vast supply chain of robotic parts, components, and specialized materials, ensuring rapid access to the necessary resources for timely repairs.

Data-Driven Insights and Continuous Improvement: Data is the lifeblood of Fix4Bot.com. The platform continuously gathers data from diagnostic processes, repair procedures, and maintenance logs. This data is analyzed to identify trends in robotic failures, refine diagnostic algorithms, optimize repair techniques, and enhance the overall effectiveness of the platform. This data-driven approach ensures continuous improvement and positions Fix4Bot.com at the forefront of robotic repair innovation.

- Commitment to Sustainability and Responsible Robotics: Fix4Bot.com is committed to sustainable practices in robot repair and maintenance. By extending the lifespan of robots through effective repair and proactive maintenance, Fix4Bot.com contributes to reducing electronic waste and promoting a more circular economy for robotic technology. Furthermore, the platform promotes responsible robotics practices and actively participates in industry initiatives focused on safety, ethical considerations, and the long-term sustainability of the robotics industry.

In conclusion, Fix4Bot.com is not just a repair service; it’s a paradigm shift in how we approach robot maintenance and longevity. By seamlessly integrating universal diagnostic capabilities, a spectrum of advanced repair techniques, proactive maintenance programs, and a global ecosystem of expertise and technology, Fix4Bot.com empowers industries and individuals alike to maximize the potential of their robotic investments, ensuring that these transformative machines continue to operate reliably, efficiently, and for years to come. In a world increasingly powered by automation, Fix4Bot.com stands as the indispensable partner, guaranteeing that the pulse of robotics remains strong, uninterrupted, and ready for the challenges and opportunities of tomorrow.

We had same in România