From Hearts to Hardware: Ensuring Unwavering Affection from Your Robot Companions with Fix4Bot.com

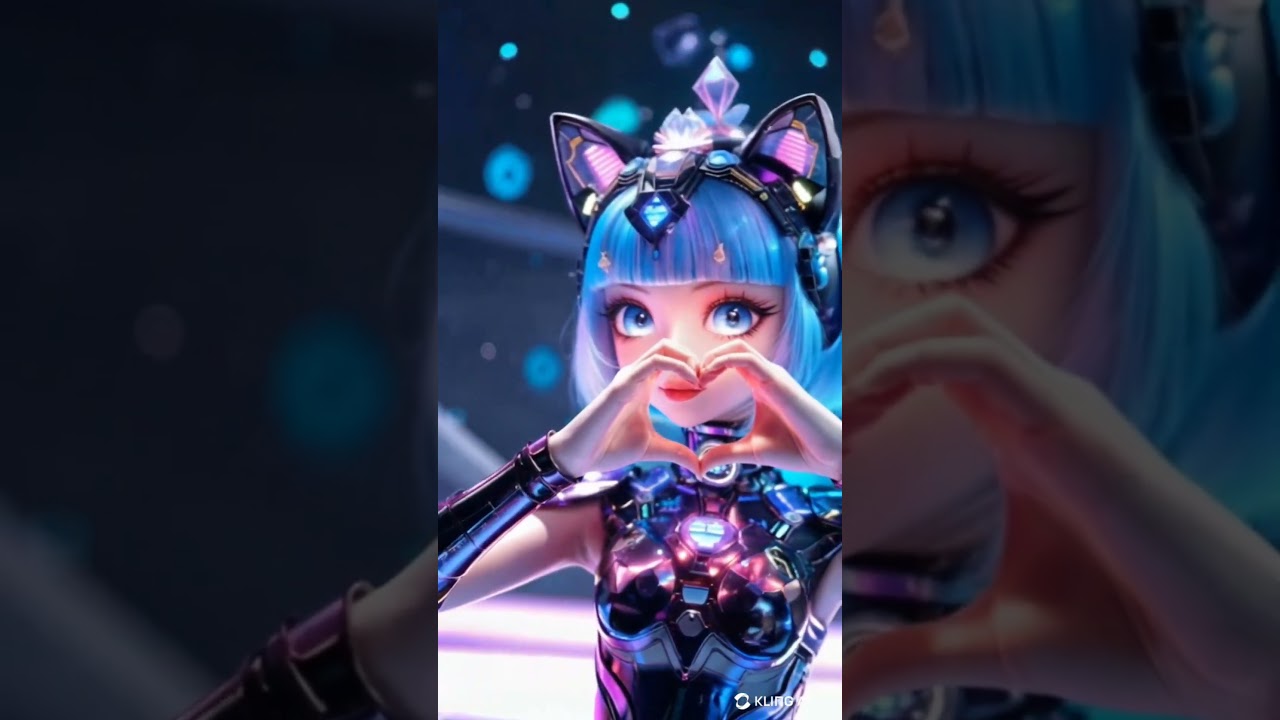

The image is undeniably charming: a cute humanoid robot, beaming with digital delight, showering the world with pixelated hearts. This visual, encapsulated in the simple Korean and English phrases "귀여운 휴머노이드 로봇이 하트를 날리며 사랑을 전하고 있어요! 💖" and "A cute humanoid robot is sending hearts and spreading love! 💕", encapsulates the burgeoning human fascination with robots, particularly those designed to interact with us on an emotional level. The hashtags – #로봇, #귀여운로봇, #애니메이션, #휴머노이드, #로봇애니메이션, #사랑, #하트, #귀여운영상, #Robot, #CuteRobot, #Animation, #Humanoid, #Love, #Heart, #CuteVideo – paint a picture of a world embracing the endearing possibilities of robotic companionship.

But what happens when the hearts stop flowing? When the adorable animation freezes, the charming gait falters, or the previously enthusiastic voice falls silent? What happens when our beloved robotic companions, from the simplest automated vacuum cleaner diligently navigating our homes to the most sophisticated humanoid assistant designed to enrich our lives, encounters the inevitable wear and tear of the real world?

This is where Fix4Bot.com steps into the spotlight, not as a nostalgic admirer of heartwarming robot animations, but as the indispensable architect of continued robotic functionality. We are not just charmed by the idea of robots; we are invested in their performance. Fix4Bot.com understands this fundamental need: the need for reliable, comprehensive, and expert robot diagnosis and repair, regardless of the complexity, manufacturer, or nature of the malfunction.

While the animated robot spreading love is a delightful representation of the future we envision, the reality of robotics is grounded in intricate engineering, complex software, and delicate hardware. Robots, in all their forms, are susceptible to a vast spectrum of potential damages. These can range from the mundane – a clogged sensor, a depleted battery, a loose wire – to the catastrophic – a major system failure, structural damage from an impact, or even software corruption rendering the robot unresponsive.

Fix4Bot.com exists to address this entire spectrum. We are not limited to a single type of robot, a specific brand, or a predetermined set of issues. Our expertise spans the entirety of the robotic landscape, from industrial automation arms laboring in factories to consumer-grade personal assistants navigating living rooms, from advanced surgical robots performing delicate procedures to exploratory robots venturing into the most hostile environments.

The Anatomy of Robotic Vulnerability: A Deep Dive into Potential Damages

To truly appreciate the comprehensive repair capabilities of Fix4Bot.com, it’s essential to understand the diverse landscape of potential robotic damages. Robots are sophisticated systems, and their vulnerabilities are as varied and nuanced as their designs. Let’s delve into a detailed examination of the categories of damages robots can face:

1. Electromechanical Failures: This is perhaps the most common category, as robots rely heavily on the seamless integration of electrical and mechanical components. Consider these examples:

- Motor Malfunctions: Motors, the driving force behind robotic movement, can fail due to overheating, bearing wear, winding burnout, or electrical shorts. Fix4Bot.com technicians possess the expertise to diagnose motor issues, from simple lubrication needs to complete motor replacement and recalibration, ensuring smooth and precise motion is restored. We utilize advanced testing equipment to pinpoint the root cause of motor failures and implement durable solutions.

- Sensor Degradation and Failure: Robots rely on a symphony of sensors to perceive their environment – proximity sensors, vision sensors, force sensors, temperature sensors, and many more. These sensors can degrade over time due to environmental factors (dust, humidity, temperature extremes), physical damage, or electrical malfunctions. Fix4Bot.com employs sophisticated sensor calibration and testing procedures to identify and rectify sensor issues, ensuring accurate environmental perception and safe operation. We can replace damaged sensors with OEM-quality components or, when necessary, upgrade to more robust and advanced sensor technologies.

- Actuator Problems: Actuators, responsible for converting electrical signals into physical actions, are crucial for robotic functionality. These can be hydraulic, pneumatic, or electric, and each type has its own set of potential failure modes. Hydraulic actuators can leak, pneumatic actuators can suffer air pressure loss, and electric actuators can experience gear stripping or electrical faults. Fix4Bot.com’s diverse expertise encompasses all actuator types. We can repair or replace damaged actuators, ensuring precise and reliable robotic movement and manipulation. This includes meticulous calibration of actuators after repair or replacement to guarantee optimal performance and accuracy.

- Wiring and Connector Issues: The intricate wiring and connectors that bind a robot together are susceptible to damage from vibration, flexing, abrasion, and corrosion. Loose connections, frayed wires, and corroded connectors can lead to intermittent failures, power loss, and signal disruptions. Fix4Bot.com technicians are adept at tracing and repairing wiring faults, meticulously soldering connections, replacing damaged connectors, and ensuring robust and reliable electrical pathways throughout the robot. We utilize specialized diagnostic tools to pinpoint even the most elusive wiring issues.

- Gear and Transmission Wear: Robots often employ complex gearboxes and transmission systems to translate motor rotations into precise and powerful movements. These mechanical components are subject to wear and tear from friction and stress. Gear teeth can strip, bearings can wear out, and lubrication can degrade, leading to backlash, slippage, and eventual failure. Fix4Bot.com offers comprehensive gearbox and transmission servicing, including cleaning, lubrication, gear replacement, bearing replacement, and precise reassembly to restore smooth and efficient power transmission.

2. Software and Firmware Glitches: Modern robots are intelligent machines, relying on sophisticated software and firmware to control their actions, interpret sensor data, and make decisions. Software malfunctions are becoming increasingly prevalent and challenging to diagnose.

- Software Bugs and Errors: Like any complex software system, robot operating systems and application software can contain bugs or errors that manifest as unpredictable behavior, system crashes, or functional limitations. Fix4Bot.com employs expert software engineers who specialize in robotic systems. We can diagnose and debug software issues, patch vulnerabilities, and update software to the latest stable versions, ensuring smooth and reliable operation. We also offer custom software solutions when required to address unique robotic challenges.

- Firmware Corruption: Firmware, the low-level software embedded directly into hardware components, is crucial for their proper functioning. Firmware corruption can occur due to power surges, improper updates, or hardware malfunctions. Fix4Bot.com possesses the tools and expertise to re-flash corrupted firmware, update firmware to the latest versions, and ensure seamless communication between hardware and software components. We maintain a comprehensive library of firmware images for various robot models.

- Network and Communication Issues: Many robots are networked systems, relying on communication networks (Wi-Fi, Ethernet, industrial protocols) to receive commands, transmit data, and coordinate with other systems. Network configuration errors, communication protocol mismatches, and hardware failures in network interfaces can disrupt robotic operation. Fix4Bot.com technicians are skilled in diagnosing network connectivity problems, troubleshooting communication protocols, and configuring network settings to ensure seamless data flow and remote control capabilities. We are proficient in a wide range of robotic communication protocols, including ROS, CAN bus, and industrial Ethernet standards.

- AI and Machine Learning Model Degradation: Robots increasingly utilize AI and machine learning models for tasks like navigation, object recognition, and decision-making. These models can degrade over time due to data drift, environmental changes, or unforeseen scenarios. Fix4Bot.com offers services to retrain and fine-tune AI models, ensuring continued accuracy and optimal performance of AI-driven robotic functions. We can also update models with the latest advancements in AI research to enhance robotic capabilities.

3. Physical Damage: The real world is often unforgiving, and robots, despite their robust designs, can suffer physical damage from various sources.

- Impact and Collision Damage: Robots operating in dynamic environments are susceptible to impacts and collisions. These can range from minor bumps to severe crashes, potentially damaging structural components, sensors, actuators, and internal electronics. Fix4Bot.com provides comprehensive physical damage assessment and repair services. We can repair or replace damaged body panels, structural members, sensor housings, and internal components. We utilize precision alignment tools to ensure proper structural integrity after repairs. In cases of severe damage, we can perform complete robot reconstruction.

- Environmental Damage (Dust, Water, Temperature Extremes, Corrosion): Robots deployed in harsh environments face constant exposure to dust, water, extreme temperatures, and corrosive substances. These environmental factors can degrade seals, corrode electrical contacts, damage sensitive components, and lead to premature wear and tear. Fix4Bot.com offers environmental damage remediation services. We can clean and decontaminate robots exposed to dust or corrosive substances, replace damaged seals and gaskets, and implement protective measures to prevent future environmental damage. We also offer specialized cleaning and maintenance procedures for robots operating in sensitive environments such as cleanrooms.

- Wear and Tear from Regular Use: Even under normal operating conditions, robots are subject to wear and tear from constant use. Joints can loosen, gears can wear down, bearings can degrade, and components can fatigue over time. Fix4Bot.com provides proactive maintenance services to address wear and tear before it leads to major failures. We conduct regular inspections, lubrication, parts replacements, and adjustments to keep robots operating at peak performance and extend their lifespan. Our preventative maintenance programs are tailored to the specific operating environment and usage patterns of each robot.

4. Power System Failures: Reliable power is the lifeblood of any robot. Power system failures can cripple robotic operations.

- Battery Degradation and Failure: Battery-powered robots, particularly mobile robots and drones, rely on batteries for their autonomy. Batteries degrade over time with repeated charge and discharge cycles, losing capacity and eventually failing. Fix4Bot.com offers battery testing, replacement, and upgrade services. We can diagnose battery health, replace depleted batteries with OEM-approved replacements, and, in some cases, upgrade to higher-capacity batteries to extend operating time. We also provide guidance on battery management best practices to maximize battery lifespan.

- Power Supply Malfunctions: Robots powered by external power supplies can experience failures in the power supply unit itself. These can be caused by component failures, voltage fluctuations, or overheating. Fix4Bot.com technicians can diagnose and repair or replace faulty power supplies, ensuring stable and reliable power delivery to the robot. We utilize specialized power supply testing equipment to pinpoint the root cause of failures.

- Charging System Problems: Robots that rely on charging systems, either wired or wireless, can experience failures in the charging infrastructure. Faulty charging cables, malfunctioning charging docks, or issues in wireless charging systems can prevent robots from recharging effectively. Fix4Bot.com can troubleshoot and repair charging system issues, ensuring robots can reliably replenish their power reserves. We are experienced in diagnosing and repairing a wide range of charging system technologies.

Fix4Bot.com: Your Partner in Robotic Uptime

Fix4Bot.com is more than just a repair service; we are your proactive partner in ensuring the continued functionality and longevity of your robotic investments. Our comprehensive approach encompasses:

- Advanced Diagnostic Capabilities: We utilize cutting-edge diagnostic tools and techniques, including:

- Non-Destructive Testing (NDT): Ultrasound, X-ray, and infrared thermography to identify internal flaws and component degradation without dismantling the robot.

- Robotic Vision and 3D Scanning: To precisely map damage and identify structural deformations.

- AI-Powered Fault Analysis: Utilizing machine learning algorithms to analyze sensor data, error logs, and operational parameters to pinpoint the root cause of complex failures.

- Endoscopic Inspection: To visualize and diagnose issues in hard-to-reach areas within the robot’s internal mechanisms.

- Functional Testing and Simulation: Rigorous testing of individual components and integrated systems to verify functionality and performance under simulated operating conditions.

- Expert Repair Technicians: Our team comprises highly skilled and certified robotic technicians with expertise in diverse robotic platforms, including:

- Mechanical Engineers: Specialized in robotic mechanics, actuators, transmissions, and structural repairs.

- Electrical Engineers: Proficient in robotic electronics, power systems, sensors, and control circuits.

- Software Engineers: Experts in robotic operating systems, firmware, communication protocols, and AI/machine learning applications.

- Mechatronics Engineers: Bridging the gap between mechanical, electrical, and software domains, providing holistic robotic system expertise.

- Robotics Specialists with Industry Certifications: Demonstrating advanced training and competency in specific robotic brands and repair methodologies.

- Genuine Parts and OEM-Quality Components: We utilize only genuine manufacturer-approved parts or high-quality OEM-equivalent components to ensure durability, reliability, and compatibility. We maintain a vast inventory of commonly used robotic parts to expedite repair turnaround times.

- Modular Repair and Component-Level Expertise: We strive for efficient and cost-effective repairs. Whenever possible, we perform modular replacements, swapping out damaged sub-assemblies. However, our expertise also extends to component-level repair, allowing us to salvage valuable components and minimize replacement costs when appropriate.

- Proactive Maintenance Programs: Prevention is always better than cure. Fix4Bot.com offers tailored proactive maintenance programs designed to minimize downtime and extend the lifespan of your robots. These programs can include:

- Regular Inspections and Diagnostics: Scheduled check-ups to identify potential issues before they escalate into major failures.

- Lubrication and Cleaning: Maintaining optimal mechanical performance and preventing environmental degradation.

- Software and Firmware Updates: Ensuring robots operate with the latest security patches and performance enhancements.

- Predictive Maintenance: Utilizing sensor data and AI-driven analysis to predict component failures and schedule preemptive maintenance, minimizing unexpected downtime and maximizing operational efficiency.

- Remote Diagnostic and Support Capabilities: For certain types of issues, Fix4Bot.com offers remote diagnostic and support services, leveraging secure remote access tools to troubleshoot software glitches, configure network settings, and guide on-site personnel through minor repairs. This minimizes downtime and reduces the need for physical technician visits in some cases.

- Customized Repair Solutions: We understand that each robot and each damage scenario is unique. Fix4Bot.com provides customized repair solutions tailored to the specific needs of your robots and your operational requirements. We work closely with our clients to understand their challenges and develop effective and efficient repair strategies.

- Comprehensive Documentation and Reporting: We provide detailed documentation of all diagnostic procedures, repairs performed, and parts replaced. This documentation ensures transparency, facilitates future maintenance, and provides valuable insights into robot performance history.

- Fast Turnaround Times: We understand that robotic downtime can be costly. Fix4Bot.com is committed to providing fast and efficient repair services, minimizing downtime and getting your robots back to work as quickly as possible. We offer expedited repair options when critical uptime is paramount.

- Global Reach and On-Site Repair Services: Fix4Bot.com provides services globally, with strategically located repair centers and mobile repair teams capable of performing on-site diagnostics and repairs at your facility, minimizing transportation costs and downtime for large or immobile robots.

Beyond Repair: Enhancing Robotic Performance and Longevity

Fix4Bot.com is not solely focused on reactive repair. We are also dedicated to helping our clients optimize their robotic deployments for enhanced performance and extended lifespan. This includes:

- Performance Optimization Services: We can analyze robot performance data and identify areas for improvement. This can include optimizing software algorithms, fine-tuning mechanical parameters, and upgrading components to enhance speed, accuracy, and efficiency.

- Robot Upgrades and Modernization: As technology advances, older robots can become outdated. Fix4Bot.com offers robot upgrade and modernization services, including retrofitting newer sensors, actuators, control systems, and software platforms to extend the lifespan and capabilities of existing robotic assets.

- Robotic Training and Consultation: We provide training programs for robot operators and maintenance personnel, empowering them to perform basic maintenance tasks, identify potential issues early, and optimize robot utilization. We also offer expert consultation services to assist with robot selection, deployment planning, and preventative maintenance strategy development.

- Recycling and Responsible Disposal Services: When robots reach the end of their functional life, Fix4Bot.com provides environmentally responsible recycling and disposal services, ensuring proper handling of electronic waste and hazardous materials in compliance with environmental regulations.

The Future of Robotic Care is Here

As robots become increasingly integrated into every aspect of our lives, from heartwarming animated companions to essential tools in industry and healthcare, the need for expert robot diagnosis and repair will only continue to grow. Fix4Bot.com stands ready to meet this challenge, offering a comprehensive suite of services designed to ensure the unwavering performance, reliability, and longevity of your robotic investments.

From the simplest sensor malfunction to the most complex system failure, Fix4Bot.com is your trusted partner in keeping your robots – whether they are showering us with digital hearts or performing critical tasks – functioning flawlessly, day in and day out. Let us handle the complexities of robotic maintenance and repair, so you can focus on harnessing the full potential of these incredible machines and enjoying the fruits of their tireless labor. Contact Fix4Bot.com today and experience the peace of mind that comes with knowing your robots are in expert hands. Because even the cutest robots deserve the best care, ensuring they can continue to spread love, and so much more, for years to come.

Leave A Comment