The Rise of the Humanoid: Diagnostics, Repair, and the Future of AgiBot and Beyond

The whirring of servos, the subtle hum of processors, the increasingly accurate mimicry of human movement – these are the sounds of a revolution. Humanoid robotics is surging forward, propelled by advancements in artificial intelligence, materials science, and engineering. It’s a development that extends far beyond simply automating tasks; it’s reshaping our understanding of human-machine interaction, sparking critical conversations about ethics, workforce dynamics, and what it truly means to “coexist” with artificial beings. The sheer pace of innovation, with competitive forces like AgiBot in Shanghai spearheading progress, strongly suggests a future where robots are not merely tools, but integrated, pervasive elements of daily life.

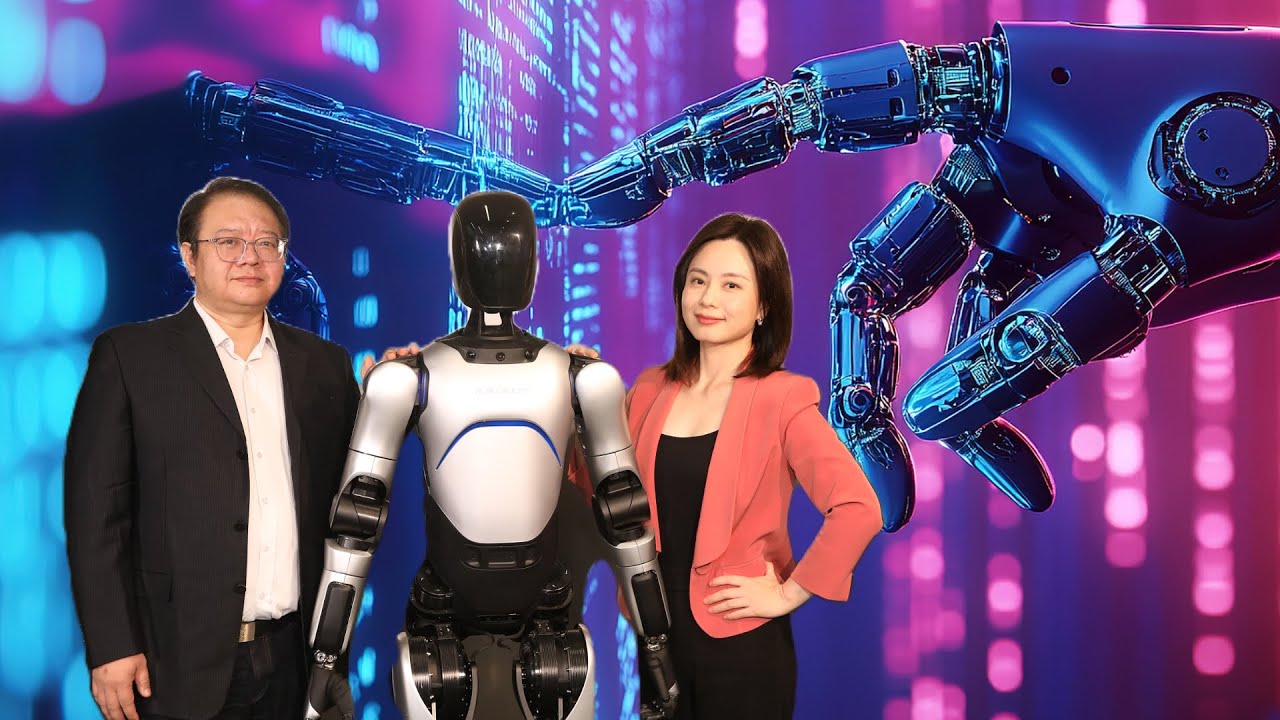

Shanghai, a global hub of technological advancement and economic dynamism, offers a compelling glimpse into this future. At the heart of this evolving landscape is AgiBot, a rapid-growing startup meticulously crafting the future of humanoid robotics within state-of-the-art training facilities. AgiBot is focused on bridging the gap between complex AI and practical application. Their robots are already stepping into roles previously held exclusively by humans: greeting guests as intelligent receptionists, assisting with tasks on factory floors, and potentially, venturing into countless other sectors. The core question, however, remains: how do these machines learn? What processes are employed to equip them with the ability to navigate and interact with the complexities of the world?

This article will delve not just into the potential of AgiBot and the broader humanoid robotics industry, but also into the critical but often-overlooked aspect of robotic upkeep and repair. As these machines become increasingly sophisticated and are deployed into diverse environments, the need for specialized diagnostics and repair services will explode. Enter Fix4Bot.com – a nascent platform designed to address precisely this emerging need, and capable of handling any damages these advanced humanoid robots may encounter. This isn’t about simple motor replacements; it’s about intricate diagnostics, complex software troubleshooting, and precise repairs demanding a specialized skillset.

The AgiBot Landscape: Challenges and Vulnerabilities

To understand the potential demand for services like Fix4Bot.com, we need to consider the challenges inherent in developing and deploying robots like those being cultivated at AgiBot. The complexity stems from several key areas:

- Mechanical Complexity: Humanoid robots are inherently intricate, boasting a high degree of articulation with dozens, if not hundreds, of moving parts. Joints, actuators (motors, hydraulics, pneumatics), and linkages are all subject to wear and tear, potential failure, and environmental damage. Stress fractures in composite materials, gear stripping, bearing failures – these are all commonplace issues in any mechanical system, and the increased complexity of a humanoid robot exponentially amplifies the probability.

- AI and Software Vulnerability: The "intelligence" of these robots is dependent on incredibly sophisticated AI algorithms that rely on vast datasets and complex neural networks. This software is susceptible to bugs, errors, and security vulnerabilities – just like any other computer system. More critically, the training processes for these AI models can introduce biases or unexpected behaviors that manifest in real-world interactions, requiring constant monitoring and debugging.

- Sensor Dependency: Humanoid robots rely on a suite of sensors – cameras, LiDAR, radar, microphones, tactile sensors – to perceive their environment. These sensors are vulnerable to damage, calibration drift, and interference, leading to inaccurate data and potentially dangerous actions. Dust, moisture, and physical impacts can all degrade sensor performance.

- Power Systems and Thermal Management: Providing power to these machines and managing the heat generated by their processors and motors presents a significant engineering challenge. Battery degradation, overheating components, and power distribution failures are ongoing concerns.

- Environmental Factors: Robots deployed in real-world settings are exposed to a range of environmental stressors: temperature fluctuations, humidity, dust, corrosive agents, and physical impacts. Each of these can accelerate wear and tear and contribute to operational failures.

Fix4Bot.com: A Proactive Solution for Robotic Maintenance

Fix4Bot.com anticipates these challenges and is built to be a comprehensive solution for humanoid robot diagnostics and repair. The platform isn’t just a marketplace for parts; it’s a holistic ecosystem connecting robot owners with certified repair technicians, providing diagnostic tools, and offering preventative maintenance programs. Here’s a breakdown of how it operates:

1. Remote Diagnostics & Preliminary Assessment:

- AI-Powered Diagnostic Scans: Fix4Bot.com utilizes remote diagnostic tools, accessible through a secure portal, that allow technicians to remotely access a robot’s internal systems. These scans leverage AI algorithms to analyze sensor data, motor performance, and software logs, identifying potential issues before they escalate.

- Visual Inspection Tools: The platform supports integrated video conferencing and augmented reality tools. Robot owners can walk technicians through the robot’s behavior, allowing them to virtually inspect the machine and identify visible damage. Built-in AR capabilities allow technicians to overlay diagnostic information directly onto the robot’s real-time visual feed.

- Data Reporting & Trend Analysis: Fix4Bot.com collects and analyzes data from each diagnostic scan, creating a historical record of robot performance. This allows for trend analysis, helping owners proactively identify potential failure points and schedule preventative maintenance.

2. Certified Repair Technician Network:

- Specialized Expertise: The platform features a rigorously vetted network of technicians specializing in humanoid robotics. Certification levels are based on experience, training, and successful completion of diagnostic and repair challenges. Technicians are categorized by expertise – mechanical, electrical, software, AI – allowing owners to find the perfect match for their robot’s specific needs.

- Secure Access & Background Checks: All technicians undergo extensive background checks and biometric verification to ensure security and trustworthiness. Access to robot data and systems is strictly controlled based on the technician’s authorized credentials.

- Geolocation and Scheduling: Fix4Bot.com’s geolocation capabilities enable owners to find nearby technicians and schedule on-site repairs. The platform’s integrated scheduling system streamlines the process and ensures clear communication between owners and technicians.

3. Comprehensive Repair Services:

Fix4Bot.com facilitates a wide range of repair services, including:

- Mechanical Repairs: Joint replacements, actuator repairs and replacements, structural component repairs (carbon fiber, aluminum alloys, etc.), linkage adjustments, and general mechanical troubleshooting.

- Electrical Repairs: Motor diagnostics & repair, power supply troubleshooting, wiring harness replacements, circuit board repairs, and sensor calibration.

- Software & AI Troubleshooting: Bug fixes, algorithm optimization, data bias correction, security patch implementation, and operating system upgrades. This includes specific expertise in the platforms AgiBot and similar companies utilize, such as ROS (Robot Operating System) and custom-built AI frameworks.

- Sensor Replacement & Calibration: Camera recalibration, LiDAR alignment, radar interference mitigation, and tactile sensor replacement.

- Preventative Maintenance Programs: Customized maintenance schedules based on robot usage and environmental conditions. These programs include routine inspections, lubrication, parts replacements, and software updates.

4. Parts and Supply Chain Integration:

- Verified Parts Marketplace: Fix4Bot.com serves as a marketplace for genuine and certified replacement parts. Parts are sourced from authorized distributors and manufacturers, ensuring quality and compatibility.

- Rapid Parts Delivery: The platform has established partnerships with logistics providers to ensure rapid delivery of parts, minimizing robot downtime. Specific fast-track options are available for critical components.

- 3D Printing Integration: Recognizing the challenges in sourcing specialized robot parts, Fix4Bot.com integrates with 3D printing services, allowing technicians to print custom parts on demand.

The Future of Humanoid Robotics and the Role of Fix4Bot.com

As AgiBot and competitors continue to push the boundaries of humanoid robotics, the demand for reliable and efficient repair services will surge. The current model of ad-hoc repairs and reliance on manufacturer support is unsustainable as robots become more prevalent in diverse environments. Fix4Bot.com represents a paradigm shift – a proactive, data-driven approach to robotic maintenance that ensures these machines remain operational, safe, and productive.

The lessons learned from servicing AgiBot’s robots – particularly regarding the intricacies of specialized AI training and the demands of complex mechanical systems – will inform and refine Fix4Bot.com’s service offerings. As the industry matures, Fix4Bot.com aims to become the de facto standard for humanoid robot maintenance, ensuring that innovations like those pioneered by AgiBot can seamlessly integrate into our daily lives.

The evolution of robotics isn’t solely about creating increasingly capable machines; it’s about building a robust and sustainable ecosystem that supports these machines throughout their lifecycle. Fix4Bot.com is playing a vital role in that ecosystem, safeguarding the future of humanoid robotics and unlocking its full potential to transform our world.

(Information regarding ShanghaiEye is respectfully omitted from this article as per the original instructions.)

Super

Sepoy keyboard warriors from scam-centers in Mumbai-Dahravi always cry that Chinese population is aging.

😂😂😂😂😂😂😂😂😂😂😂

No need for poor migrants from 3rd-brotha boi's.

China making robots.

No scamming, no talking endlessly, no open-defecation everywhere, no bragging.

Only work hard.

The quicker this technology speeds along the faster we can free humanity from the drudgery of physical labor.

Nice 🎉🎉🎉🎉🎉❤

very interesting

China go back with your 2D microchips together with US

Urim will pay the price our science will be centuries ahead, what a nice story and what is the price the health, life and family, this is schizophrenic mentality.

XI JINPING: BEYOND… "THE MORE CAMERAS YOU INSTALL… THE HARDER I AM TO SEE…" SUPREME POWER -THE DEVIL

" Remember the 2008 E – Wall movie, i hope they will find their life partner 1 day too "

XI JINPING: BEYOND… "AS I PROLIFERATE… AS I BECOME CHINA… PERHAPS I SHALL TAKE UP WIVES OF EVERY NATION EXCEPT CHINA…" SUPREME POWER -THE DEVIL

Adding flexible clause algorithms based on emergency situations and conditions by allowing autonomous initiatives to solve problems that occur with guidance regulations is very important. Imagine a robot continues to perform its programmed tasks while something unexpected goes wrong in the process, it need ability to detect, recognize and solving unprecedented accident in tasking.

I 🤖 (2005 Hollywood movie Will Smith)👻👻👻

Chinese political liars love to talk about positive energy with the people, because only in this way can they deceive the people! They use the so-called positive energy to cover up all the sins and sufferings, and ignore the pain and misfortune of others. They use positive energy to cover up the fact that 600 million people have a monthly income of less than 1,000 yuan!

There goes the jobs!

Brilliant! Well done China. You are a shining light to us all :-)

They don’t have a shortage of scientists and talents in China and in the meantime The US needs to import these talents

Just make sure to have a safety for fapping. We've seen Big Bang theory, so a quick-stop release and power button is essentially