Breathe New Life into Your Robot: How Fix4Bot.com Diagnoses & Repairs Any Robotic Damage

The whirring gears, precise movements, and undeniable charm of robots captivate us. Whether it’s a beloved household companion, a sophisticated industrial workhorse, or a high-end hobbyist project, robots offer incredible utility and entertainment. But even the most advanced robots are vulnerable to damage. Accidents happen. Components fail. Software glitches arise. When your robot needs help, Fix4Bot.com stands ready to diagnose and repair virtually any robotic issue, no matter the complexity or brand. This article explores the breadth of our diagnostic capabilities, the repair techniques we employ, and the underlying technology that ensures we restore your robot to optimal performance.

A Multifaceted Approach to Robotic Diagnostics

At Fix4Bot.com, we don’t simply replace parts. Our philosophy revolves around meticulous diagnostics – understanding the root cause of the problem before attempting any repair. This involves a layered approach, blending experienced intuition with cutting-edge technology.

- Initial Assessment & Data Gathering: The process begins with a thorough initial assessment. This includes collecting comprehensive information from the owner: How the damage occurred, the robot’s operating history, recent modifications, and any observed behaviors prior to the failure. Pictures and videos are invaluable tools at this stage, offering visual clues that might be missed during a physical inspection. For software-related issues, access to the robot’s programming, logs, and configuration files is essential.

- Physical Inspection and Component Testing: Our technicians conduct a meticulous physical inspection, looking for visible damage like cracks, dents, broken wires, or signs of water ingress. We use high-powered magnification to identify micro-fractures or corrosion that could be contributing to the problem. Component testing is a crucial part of the diagnostic process. We utilize a range of tools, including:

- Multimeters: To accurately measure voltage, current, and resistance across circuits and components.

- Oscilloscopes: To visualize electrical signals and identify anomalies in waveforms, revealing problems like signal distortion or timing issues.

- Logic Analyzers: To analyze digital signals and decipher the communication patterns between different components in the robot’s control system.

- Thermal Imaging Cameras: To detect overheating components, which can indicate failing electronics or inefficient power delivery.

- Robotic Specific Diagnostic Software: We maintain a library of manufacturer-specific diagnostic tools for popular robot brands. These tools allow us to interface directly with the robot’s onboard computer and retrieve error codes, sensor data, and other valuable diagnostic information.

- Software and Firmware Analysis: Many robotic failures are rooted in software or firmware issues. We possess extensive expertise in analyzing robot software, identifying bugs, corrupted files, or conflicting code. Our team is skilled in:

- Reverse Engineering: Analyzing proprietary software to understand its functionality and identify potential vulnerabilities or errors. Note: This is performed ethically and legally, only for diagnostic purposes and with the consent of the owner.

- Firmware Flashing and Updating: We can safely flash new firmware to resolve known bugs, improve performance, or adapt the robot to new environments.

- Debugging Robotics Control Systems (ROS, etc.): We are proficient in debugging robotics operating systems like ROS, allowing us to pinpoint errors in algorithms and control loops.

- Simulated Environment Testing: Whenever possible, we recreate the robot’s operational environment within a controlled setting. This allows us to observe its behavior under simulated conditions, identify triggering factors, and test the effectiveness of repairs. This is especially crucial for robots designed for specific tasks, like cleaning or delivery, as it helps validate the fix within the intended use case.

The Art and Science of Robotic Repair: A Toolkit of Techniques

Once the root cause of the problem is identified, our skilled technicians employ a diverse range of repair techniques, drawing upon expertise in mechanical engineering, electrical engineering, and software development.

- Mechanical Repairs and Component Replacement: Physical damage is a common issue. We handle a remarkable array of mechanical repairs:

- Chassis Fabrication and Repair: Repairing or recreating damaged chassis components using techniques like welding, 3D printing, and composite material repair.

- Actuator Replacement/Repair: Replacing or rebuilding motors, servos, and linear actuators. We have access to a vast network of parts suppliers and can often source even rare components.

- Gearbox and Transmission Repair: Disassembling, inspecting, and repairing gearboxes and transmission systems, replacing worn gears, bearings, and lubrication.

- Sensor Calibration and Replacement: Precisely calibrating sensors (encoders, gyroscopes, accelerometers) to ensure accurate feedback to the robot’s control system. Replacing faulty sensors with compatible models.

- Wheel and Track Repair/Replacement: From simple tire replacements to complex track system rebuilds, we address all locomotion-related mechanical issues.

- Electrical Repairs & Circuit Board Troubleshooting: Robotics relies heavily on intricate electronics. Our expertise in this area is critical:

- Circuit Board Repair: Using micro-soldering techniques, we repair damaged traces, replace surface-mount components, and address corrosion on printed circuit boards (PCBs). We’ve invested in specialized equipment, including hot air rework stations and precision soldering irons, to handle delicate electronic components.

- Wiring Harness Repair: Identifying and repairing broken or frayed wires, replacing connectors, and re-routing harnesses to prevent future damage.

- Power Supply and Battery Management System (BMS) Repair: Diagnosing and repairing power supply irregularities and battery management system issues, including replacing faulty batteries and BMS components.

- Motor Driver Circuitry Repair:Repairing or replacing motor driver circuits, which are often points of failure due to the high currents involved.

- Software and Firmware Modifications: Beyond simple bug fixes, we can customize robot software to improve performance or adapt it to new tasks.

- Algorithm Optimization: Refining existing algorithms to improve efficiency, accuracy, and responsiveness.

- Custom Scripting: Developing custom scripts to automate tasks, add new features, or integrate the robot with other systems.

- Communication Protocol Integration: Integrating new communication protocols to allow the robot to interact with other devices.

- ROS Package Development and Modification: Creating and modifying ROS packages to tailor the robot’s behavior and functionality.

Technology Empowering Our Repair Capabilities

Fix4Bot.com leverages a range of advanced technologies to enhance our diagnostic and repair capabilities:

- 3D Printing for Rapid Prototyping and Part Replacement: We utilize 3D printing to quickly create custom parts when replacements are unavailable or to prototype solutions to unique design challenges. This significantly reduces repair time and cost. We utilize both FDM (Fused Deposition Modeling) and SLA (Stereolithography) printers to produce parts with varying levels of detail and strength.

- Micro-Soldering and BGA Rework Stations: These precision tools allow our technicians to repair surface-mount components and ball grid array (BGA) chips with exceptional accuracy and minimal risk of damage.

- X-Ray Inspection Systems: For internal component inspection, particularly in densely populated circuit boards, X-ray systems provide non-destructive visual access.

- Finite Element Analysis (FEA) Software: When dealing with structural failures, FEA software helps us analyze stress distribution and optimize designs for increased durability.

- Computer-Aided Design (CAD) Software: We use CAD software to create and modify 3D models of robotic components, enabling us to design custom parts and fixtures.

- Robotic Testing Platforms: Simulated environments resembling real-world applications, for example, a miniature obstacle course for a navigation robot, allow comprehensive performance testing post-repair.

- Remote Diagnostics & Secure Data Transfer: Utilizing secure remote access protocols, we assist clients in initial troubleshooting or gather data remotely for more complex analysis before a repair is started.

Addressing Common Robotic Failures – Examples

To illustrate our capabilities, here are a few common robotic failures and how Fix4Bot.com approaches them:

- Roomba Battery Degradation: We routinely diagnose and replace weakened Roomba batteries, ensuring proper charging and discharge cycles. We also inspect the BMS for damage or malfunction.

- Drone Motor Failure: Drone motor failures can be due to overheating, bearing wear, or electrical faults. We test the motor windings, bearings, and connections, and replace the motor if necessary.

- Industrial Robot Joint Issues: Industrial robots often experience joint stiffness, inaccurate positioning, or motor errors. We diagnose these issues by analyzing sensor data, inspecting gearboxes, and testing motor performance.

- Educational Robot Software Glitches (LEGO Mindstorms, VEX Robotics): Debugging software and firmware is the primary focus for these platforms. We utilize debugging tools, code analysis techniques, and manufacturer-provided resources to resolve errors.

- Security Robot Navigation Problems: Issues with navigation often involve sensor malfunctions (lidar, cameras) or algorithm errors. We meticulously calibrate sensors and refine navigation algorithms to ensure accurate obstacle avoidance and path planning.

Conclusion: Restoring Your Robot’s Potential

Fix4Bot.com is committed to being the premier robotic repair service. Our blend of skilled technicians, advanced technology, and a dedication to thorough diagnosis ensures that we can tackle virtually any robotic damage, from minor mechanical issues to complex software failures. We go beyond simply fixing problems; we aim to restore your robot to its full potential, extending its lifespan and maximizing its value. Contact us today for a consultation and let us breathe new life into your robotic investment.

I guess we can't use water to destroy them.

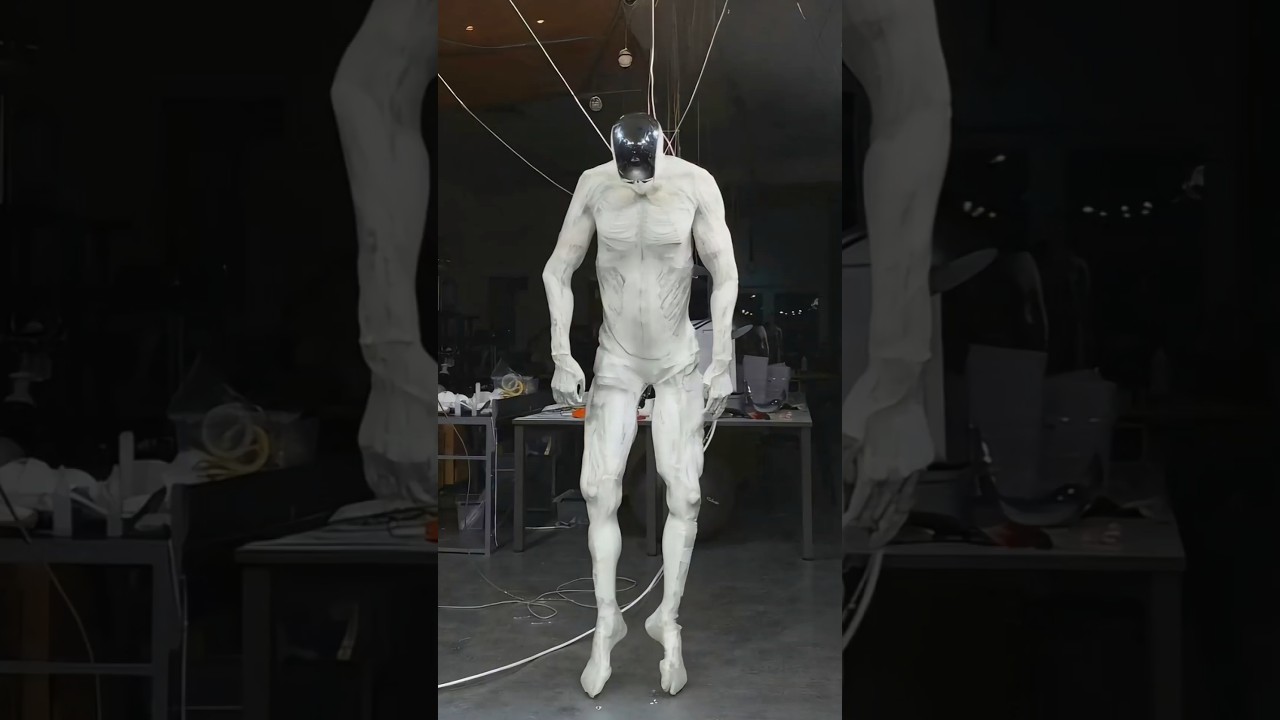

https://www.youtube.com/shorts/b1Pq_QEQdoU

Uncanny valley hitting hard

AM!???

If the muscles are made of metal then that’s pretty much a warframe

I think he will need to carry a wagon of hydrolic pumps behind him until the can find an alternative for air. Muscle fibers are more like rubber bands that are alive. I think you need at least at last signals from a human nervous system at minimum to make artificial muscles work. Our minds perform the fine-tuning needed to be autonomous. This is why FAVs will not work. Our bodies have countless receptors wired into our nervous systems constantly processing corrections.

I will truly be scared when I see a bot that can truly observe and process its environment. I don't think we should attempt to go there. Many writers have theorized the dangers and repercussions.

he looks like scp 096

fallout is slowly becoming real

Give ma boy some coffe☕