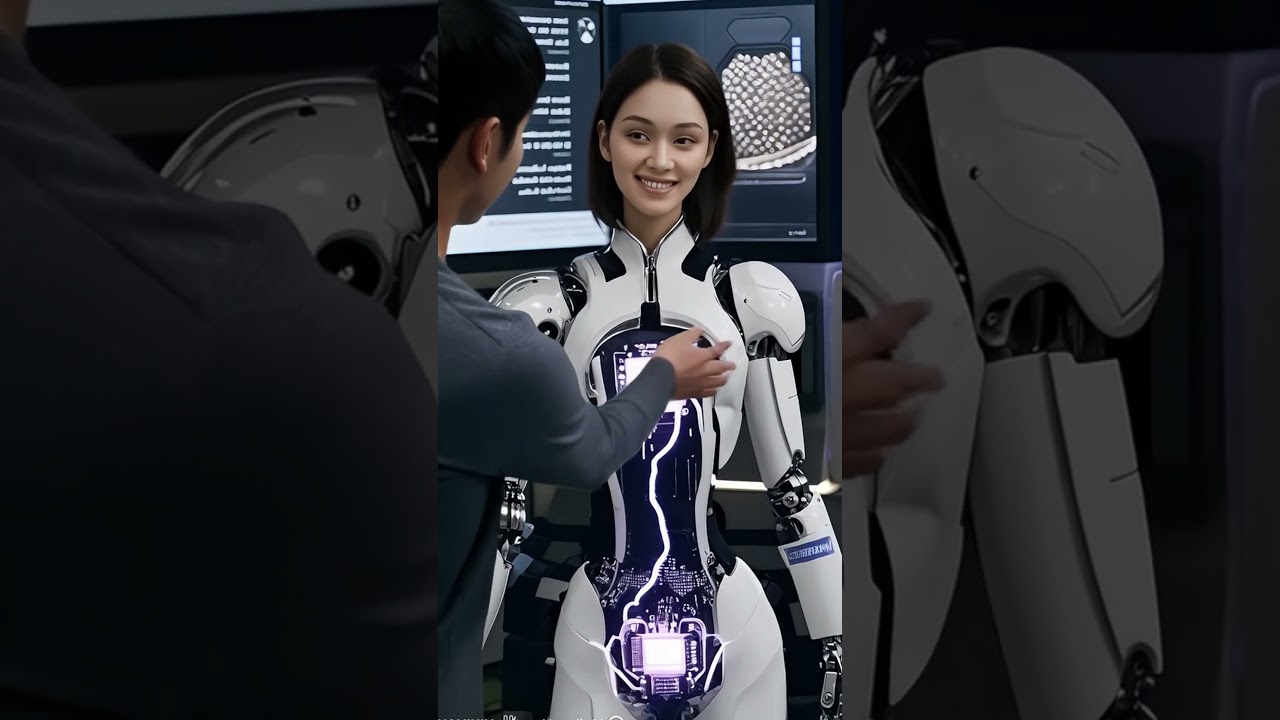

Resurrecting Your Robotic Companion: Fix4Bot.com – Your Complete Repair & Diagnostics Hub

Robots are no longer a futuristic fantasy; they’re integral to our lives, from industrial automation and logistics to domestic helpers and entertainment. As these complex devices become increasingly pervasive, so too does the inevitable: they break down. And while the prospect of a malfunctioning robot can be daunting, the process of diagnosis and repair doesn’t have to be. Enter Fix4Bot.com, a comprehensive online platform dedicated to providing expert robot diagnostics, repair services, parts sourcing, and preventative maintenance solutions – essentially, your one-stop shop for keeping your robotic companion operational.

This article delves into the capabilities of Fix4Bot.com, exploring its diagnostic tools, repair methodologies, the tech powering its services, and how it handles a wide spectrum of potential robotic ailments. We’ll cover everything from simple software glitches to intricate hardware failures, offering a detailed perspective on what Fix4Bot can do to resurrect your robotic investment, ensuring longevity, optimal performance, and ultimately, peace of mind.

The Diagnostic Landscape: Pinpointing the Problem

Fix4Bot.com’s core strength lies in its robust diagnostic capabilities. Recognizing that a successful repair begins with an accurate assessment, the platform leverages a multi-faceted approach to identify the root cause of a robot’s malfunction.

- Remote Diagnostics & Data Logging: For robots equipped with telematics and data logging capabilities – a growing subset of modern robots – Fix4Bot allows secure remote access for diagnostics. This involves leveraging industry-standard secure protocols to access the robot’s internal logs, sensor data, error codes, and performance metrics. Analyzing this data provides a high-resolution snapshot of the robot’s operation leading up to the failure, uncovering subtle anomalies that may be invisible through traditional visual inspection. This approach is particularly valuable for complex industrial robots and autonomous vehicles. Specific software such as ROS (Robot Operating System) can transmit diagnostic data, which Fix4Bot’s platform is engineered to interpret.

- Guided Troubleshooting Algorithms: The platform incorporates an extensive library of troubleshooting algorithms, designed to guide users through a series of tests and observations. These algorithms are model and function-specific, catering to a vast array of robot types. The user answers a series of questions relating to the observed symptoms, enabling the system to narrow down the likely causes of the problem and recommend initial diagnostic steps. This guided approach is perfect for users with limited technical expertise.

- Advanced Signal Analysis: For robots relying on sensors, Fix4Bot’s platform incorporates advanced signal analysis tools. This is crucial for identifying issues with perception systems (cameras, LiDAR, sonar) or sophisticated control systems. For instance, analyzing camera feeds for distortion, noise, or missing data can indicate a faulty lens, sensor malfunction, or even interference. Similarly, analyzing LiDAR point clouds can reveal issues with accuracy or range.

- Physical Inspection Checklists & Remote Expert Consultation: While remote diagnostics offer significant advantages, physical inspection remains vital. Fix4Bot provides detailed checklists tailored to specific robot models, guiding users through a structured physical examination. High-resolution imagery and video documentation tools are integrated to allow Fix4Bot’s expert technicians to remotely assess the robot’s condition – think of it as a virtual on-site consultation.

Repair Strategies: A Spectrum of Solutions

Once the diagnosis is confirmed, Fix4Bot.com offers a tiered system of repair solutions, ranging from simple software fixes to complex hardware replacements and custom fabrication:

- Software Troubleshooting & Updates: A significant portion of robot malfunctions stem from software glitches. Fix4Bot’s platform grants access to a library of known issues and readily available software patches. The platform also facilitates remote software updates, ensuring the robot is running the latest firmware and benefiting from bug fixes and performance improvements. Real-time monitoring and automated updates are offered for compatible robots, preventing future issues.

- Component Replacement & Sourcing: One of Fix4Bot’s key differentiators is its access to a vast network of robotics component suppliers. Whether it’s a replacement motor, a faulty sensor, a damaged circuit board, or even a custom-designed actuator, Fix4Bot can source the necessary parts quickly and efficiently. Their database integrates with numerous global suppliers, ensuring competitive pricing and fast delivery.

- Circuit Board Repair & Refurbishment: Damaged or malfunctioning circuit boards are a common headache in robotic repair. Fix4Bot performs micro-soldering repairs, component replacement, and circuit board refurbishment at their specialized facilities. They utilize advanced rework stations and equipment like hot air reflow devices and BGA repair machines to address a wide range of PCB (Printed Circuit Board) faults. This capability significantly extends the lifespan of robotic systems, avoiding costly board replacements.

- Mechanical Repair & Fabrication: Robots are physical machines subject to wear and tear. Fix4Bot’s engineers employ 3D printing, CNC machining, and traditional fabrication techniques to repair or replace damaged mechanical components – gears, bearings, linkages, and housings. For robots requiring custom modifications or replacements for obsolete parts, Fix4Bot’s rapid prototyping and fabrication services provide a valuable solution. Considerations for material selection – aluminum alloys, polymers, composites – are factored in based on the robot’s operational environment and requirements.

- Actuator Repair & Rewinding: Actuators, especially motors and encoders, often fail during intensive operation. Fix4Bot offers actuator repair and rewinding services, restoring them to their original performance specifications. This process includes disassembling the actuator, diagnosing the fault (e.g., damaged windings, bearing failure), replacing faulty components, and testing the actuator to ensure optimal functionality.

- Custom Programming & Firmware Modification: Some problems extend beyond hardware and software; they require specific programming adjustments. Fix4Bot’s software engineers can modify existing firmware, implement custom control algorithms, or even rewrite entire robotic programs to address unique challenges or integrate new functionalities. This includes expertise in robot programming languages like C++, Python, and ROS.

The Technology Behind Fix4Bot: A Blend of Innovation

Fix4Bot.com isn’t just a repair service; it’s a platform built on cutting-edge technologies designed to optimize diagnostics and streamline the repair process.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms play a vital role in several aspects of Fix4Bot’s operations. Machine learning models are trained on vast datasets of robot failure data (anonymized and aggregated), allowing the system to predict potential failures based on operational patterns and sensor data. This predictive maintenance capability allows users to proactively address issues before they lead to catastrophic breakdowns. Anomaly detection algorithms identify deviations from normal behavior, flagging potential problems.

- Augmented Reality (AR) Assistance: Fix4Bot utilizes AR technology to enhance the repair process. Technicians can use AR overlays on their mobile devices to display step-by-step repair instructions, identify component locations, and receive real-time guidance from remote experts. This reduces errors and accelerates the repair process.

- Cloud-Based Platform & Data Management: The entire Fix4Bot system is built on a robust cloud infrastructure, enabling seamless data sharing, remote access, and collaboration between users and Fix4Bot’s engineers. All diagnostic data, repair logs, and component information are securely stored and managed in the cloud, providing a comprehensive history of each robot’s maintenance.

- Internet of Things (IoT) Integration: For robots with IoT capabilities, Fix4Bot can directly integrate with their existing communication channels, enabling real-time data monitoring and automated diagnostics. This allows for proactive issue detection and remote troubleshooting, minimizing downtime.

- Robotic Process Automation (RPA): To streamline repetitive tasks involved in component sourcing, order processing, and data analysis, Fix4Bot utilizes RPA technology. This reduces manual intervention and improves overall efficiency.

Addressing Specific Robotic Damage Scenarios

Fix4Bot’s capabilities extend across a broad range of robot types and common damage scenarios:

- Industrial Robots (e.g., ABB, Fanuc, KUKA): Common issues include motor failures, encoder malfunctions, controller errors, and damaged end-effectors. Fix4Bot’s expertise in industrial robot control systems, combined with their component sourcing network, makes them well-equipped to handle these challenges.

- Service Robots (e.g., delivery robots, cleaning robots): Software glitches, navigation system errors, sensor failures (LiDAR, cameras), and battery degradation are common. Fix4Bot can address these issues through software updates, sensor calibration, battery replacement or refurbishment, and navigation system optimization.

- Medical Robots (e.g., surgical robots): These robots require specialized expertise and meticulous attention to detail. Fix4Bot maintains a team of engineers with experience in medical device repair, adhering to strict regulatory standards and utilizing calibrated equipment.

- Consumer Robots (e.g., robotic vacuum cleaners, toy robots): While simpler than industrial models, maintaining these robots still requires specialized knowledge. Fix4Bot provides repair services for a wide range of consumer robots, addressing issues like motor failures, battery problems, and sensor malfunctions.

- Autonomous Vehicles (e.g., drones, self-driving cars): These complex systems often require comprehensive diagnostic capabilities and specialized repair techniques, including sensor fusion diagnostics, LiDAR calibration, and autonomous driving software troubleshooting.

Preventative Maintenance: Extending Robot Lifespan

Beyond reactive repairs, Fix4Bot.com emphasizes proactive preventative maintenance. The platform offers customized maintenance schedules based on the robot’s usage patterns and operating environment. Regular diagnostics, software updates, and component inspections can significantly extend the robot’s lifespan and prevent costly breakdowns. Fix4Bot’s system provides alerts and recommendations for preventative maintenance activities, ensuring optimal performance and reliability.

Conclusion: Your Partner in Robot Longevity

Fix4Bot.com represents a significant advancement in robotics maintenance and repair. By combining advanced diagnostic tools, a comprehensive repair skillset, and innovative technologies like AI, AR, and cloud computing, Fix4Bot offers a uniquely powerful platform for keeping robotic systems running smoothly. Whether you’re facing a sudden breakdown, seeking to optimize performance, or planning for long-term preventative maintenance, Fix4Bot.com is your trusted partner in ensuring the longevity and reliability of your robotic investments.

Visit Fix4Bot.com today to explore their services and discover how they can help you resurrect your robotic companion.

Esta linda 🎉🎉

❤❤❤❤❤❤❤😅

വളരെ നല്ലത്

не робот😊

Мне не понятно почему она пикает только тогда когда её трогают за грудь

Animated

Ez egy csali

🎉😢😢😮

Ước gì trúng vé số giải Độc đắc mua 1 em gái robot về ngắm nghía đỡ cô đơn

Haa mai karna chahti hoo

कवर पहनाया है लड़की असली है

perfección de oura piel nada de partes plásticas todita con piel que no se distinga lo humano con lo artificial a perfeccionar las hasta sean mujeres

Trickaufnahme. Nur der Kopf ist echt!

Isay bananay ka cost Kitna aayega.

Or market may kitnay may milayga?

If more than 10 lac then drop the productions.imean production it is of no use.

Sale chedna nahi. Joote padega

Robot wah aku seng melihat nya

Chitchitper🎉🎉🎉🎉🎉🎉🎉🎉🎉🎉❤❤❤❤❤❤❤❤❤❤❤

Nice ❤❤🎉🎉

পবিত্র কোরআনে উত্তম শিক্ষা।

“সুদ নেওয়া পাপ।"

কোরান মজিদ, সুরাঃ আল-বাকারা – ২, আয়াত ২৭৬:— "আল্লাহ সুদ নেওয়া ব্যক্তিকে ধনশূন্য করে দেন, অর্থাৎ নাশ করে দেন, এবং দান করা ব্যক্তিকে ভরিয়ে দেন।"

पवित्र कुरान में अच्छी शिक्षा।

''ब्याज लेना पाप है‘‘

कुरआन मजीद सूरः अल् बकरा—2 आयत नं. 276 :— अल्लाह ब्याज लेने वाले का मठ मार देता है यानि नाश कर देता है और (खैरात) दान करने वाले को बढ़ाता है।

Надо о ролике и картинках подумать: … Воздержался…

Mau semaju n secerdas apapun manusia di dunia ini, robot yah tetap robot ,, mandre di ongkos 🤔

O lá ele 😮 Deus e mais…

Tốt lắm các nhà khoa học nguyên cứu hàng đầu thế giới

เอาคนมาใส่ชุด

milhões passando fome e necessidade e se preocupam em construir coisas inúteis 👎

As pessoas já morreram nem sabe

Idiot it's just a suit

Alita

Alita

For nothing !

May. I kiss you, my dear!!!

영화처럼 기계에 지배 당하는 세상이 올까봐 겁난다.

Os seres humanos estão lascados

O Deus da máquina Mquitrom está chegando

Só nos resta ajuda de Jesus e o exterminador do futuro 😂😂😂😂😂😂

I want purchase

كم ساع تعمل

Esto será un drama ..los yihadistas los usaran de soldados y terroristas..rusos ,yihadistas .. comunismo..serán los futuros soldados terroristas …esto hay que frenarlo ya . …y los degenerados los usaran para el morbo y la promiscuidad ..sera un asco …😢

Nice she smile😊