Beyond the Hype: Diagnosing and Repairing the Complexities of Advanced Robotics – A Fix4Bot.com Perspective

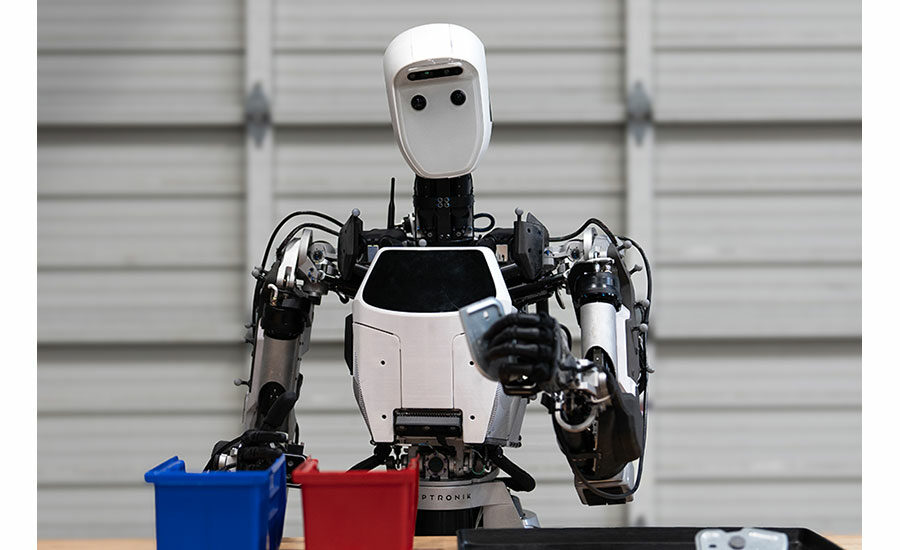

The world of robotics is accelerating at a breathtaking pace. From Tesla’s Optimus humanoid to the increasingly sophisticated Sanctuary AI and Ameca, the lines between science fiction and reality are blurring. However, behind the dazzling demonstrations and ambitious pronouncements lies a critical, often-overlooked challenge: maintaining and repairing these incredibly complex machines. While the media often focuses on breakthroughs like self-replicating robots or revolutionary operating systems, the mundane – yet vital – task of troubleshooting and repair remains largely unexplored.

This is where Fix4Bot.com steps in. We’re not just enthusiasts; we’re a dedicated team of robotics engineers, technicians, and specialists committed to providing comprehensive diagnostic and repair services for advanced humanoid robots – including, crucially, the emerging class of robots showcased in recent media buzz like the Tesla Optimus.

This article examines the specific challenges entailed in maintaining and repairing these next-generation robots, drawing insights from recent developments and highlighting how Fix4Bot.com is uniquely equipped to address them. We’ll move beyond the surface level excitement, addressing the underlying engineering complexities and the need for specialized expertise. We will also consider the implications of recent news and trends like Tesla’s price adjustments, investor reactions, and the rapid advancements in humanoid robotics.

The Unique Challenges of Humanoid Robot Repair & Diagnostics

Traditional industrial robots, while sophisticated, typically operate within controlled environments, performing repetitive tasks. Humanoid robots, on the other hand, are designed to navigate and interact with the complex, unpredictable world around them. This functionality introduces a host of new challenges for diagnostics and repair:

- Integrated Systems: Humanoid robots aren’t simply collections of parts. They are intricate ecosystems of mechanics, electronics, software, and AI. A seemingly simple issue, like a stumble, could be the result of a motor malfunction, sensor error, software glitch, or even a calibration problem in the robot’s perception system. Diagnosing the root cause requires a holistic approach.

- Proprietary Software & Hardware: Companies like Tesla, Sanctuary AI, and others utilize highly proprietary software and hardware architectures. Access to diagnostic tools, schematics, and firmware updates is often restricted, making repairs challenging and requiring specialized knowledge and partnerships.

- Advanced Actuation: Humanoid locomotion demands advanced actuation systems. Electric motors, hydraulic systems, pneumatic actuators, and increasingly, artificial muscles, all present unique diagnostic and repair considerations. Precision and specialized equipment are required to maintain and fix these components.

- Sensor Fusion and Perception: Humanoid robots rely on a sophisticated blend of sensors – cameras (RGB, depth, thermal), LiDAR, radar, inertial measurement units (IMUs), force/torque sensors, and tactile sensors – to perceive the world. Errors in sensor data or the algorithms that process it can lead to unpredictable behavior. Diagnosing these issues often requires advanced signal processing and machine learning expertise.

- AI and Machine Learning Dependence: The core intelligence of a humanoid robot resides in its AI and machine learning models. Problems within these models – corrupted training data, algorithmic biases, or simply poorly tuned parameters – can manifest as erratic behavior and are difficult to trace.

- Dexterous Manipulation: Humanoid hands are arguably the most complex mechanical systems ever created. Repairing damaged fingers, joints, or tactile sensors requires micro-precision tools and a deep understanding of biomechanics and robotics.

- Safety Concerns: Repairing these robots, especially when they are actively powered, presents significant safety risks. Robust safety protocols and specialized training are essential to protect technicians and prevent further damage.

- Material Science and Durability: Humanoid robots are built using a mix of advanced materials – lightweight alloys, carbon fiber composites, and specialized polymers – often subjected to considerable stress and strain. Assessing material degradation, cracks, or stress fractures is crucial for preventative maintenance and identifying potential failure points.

Decoding Recent Trends: Implications for Robot Maintenance

Several recent trends highlighted in headlines about robotics specifically impact the maintenance and repair landscape:

- Tesla’s Optimus Updates & Self-Replication: Tesla’s recent demonstration of Optimus making another Optimus is undeniably impressive. However, it also highlights the potential for increased robot density. More robots inevitably mean more maintenance requirements, demanding scalable diagnostic and repair solutions. Furthermore, the hardware and software used in self-replication will likely be extremely complex – and proprietary – requiring specialized expertise.

- Market Volatility and Price Adjustments: Tesla’s stock dips, and subsequent price cuts, as observed according to media reports, suggest a shift in market strategy. If the goal is to drive adoption and reduce costs, expect increasingly rapid production cycles and potentially a greater prevalence of Optimus units in various environments. This accelerated deployment increases the need for accessible and responsive repair services.

- Cathie Wood’s Investment & Market Perception: The reported decision by Cathie Wood to reinvest in Tesla during a market dip demonstrates continued faith in the company’s long-term vision. This reinforces the likelihood of continued investment in robotics and the subsequent expansion of the market. As the market matures, standardized repair protocols and accessible parts will become crucial.

- Ameca’s Locomotion Breakthrough: Ameca’s achievement of walking is a significant milestone. Bipedal locomotion is inherently challenging, placing immense stress on the robot’s legs, actuators, and control systems. We can anticipate increased wear and tear on these components, significantly impacting maintenance schedules and repair frequency.

- Sanctuary AI and Tactile Sensing: Sanctuary AI’s focus on sophisticated tactile sensing indicates a commitment to robots that can interact with the world in a more nuanced and safe way. While beneficial for functionality, these tactile sensors present new diagnostic challenges – ensuring they are properly calibrated and protected from environmental factors.

- The Power of Operating Systems: The concept of a single operating system "eating the world" (as Tony Seba suggests) is ambitious but speaks to the burgeoning standardization movement. The successful adoption of a universal operating system is likely to greatly simplify diagnostics and repairs, as it reduces hardware and software complexities.

Fix4Bot.com: A Comprehensive Solution for Humanoid Robot Diagnostics and Repair

Fix4Bot.com is built to address these evolving challenges. We offer a range of services tailored to the unique demands of advanced humanoid robots:

- Remote Diagnostics: Leveraging advanced telematics and remote access capabilities, we can diagnose a wide range of issues without the need for on-site visits. This is particularly valuable for robots operating in remote or geographically dispersed locations.

- On-Site Repair Services: Our certified technicians are equipped with the specialized tools and expertise to perform on-site repairs, minimizing downtime and maximizing operational efficiency.

- Preventative Maintenance Programs: We offer customized preventative maintenance programs designed to proactively identify and address potential issues before they escalate into costly repairs. These programs are tailored to each robot’s specific operating environment and usage patterns.

- Component Replacement & Hardware Customization: We maintain a comprehensive inventory of spare parts for many leading humanoid robot platforms. We also offer hardware customization and modification services to address specific application requirements.

- Software Diagnostics & Optimization: Our software specialists can diagnose and resolve software glitches, optimize AI models, and provide firmware updates to ensure optimal performance.

- Sensor Calibration & Alignment: Accurate sensor data is critical for proper robot operation. We provide meticulous calibration and alignment services for all types of sensors, including cameras, LiDAR, radar, and IMUs.

- Material Degradation Analysis: Using non-destructive testing techniques, we can evaluate material integrity and identify potential areas of weakness.

- Reverse Engineering & Legacy Support: We specialize in providing support and repair services for older or discontinued robot models where manufacturer support is no longer available.

- Training and Education: Fix4Bot.com offers customized training programs for in-house maintenance teams, empowering them to perform basic diagnostics and repairs.

Looking Ahead: The Future of Robot Maintenance

The robotics landscape is constantly evolving. Fix4Bot.com is committed to staying at the forefront of this revolution, continuously expanding our expertise and investing in the latest diagnostic and repair technologies.

We envision a future where:

- AI-Powered Diagnostics: AI and machine learning will play an increasingly important role in robot diagnostics, enabling predictive maintenance and automated fault detection.

- Modular Robot Designs: The trend towards modular robot designs will simplify repairs and facilitate the replacement of damaged components.

- Standardized Repair Protocols: Industry-wide standardization of repair procedures and parts will improve accessibility and reduce costs.

- Augmented Reality (AR) Assistance: AR technology will provide technicians with real-time guidance and remote support during repairs.

- Self-Healing Robotics: The development of self-healing materials and automated repair systems will significantly reduce the need for human intervention.

Conclusion: Ensuring the Reliability of the Robotic Future

The remarkable advancements in humanoid robotics hold enormous potential to transform our world. However, realizing this potential requires a commitment to ensuring the reliability and longevity of these complex machines. Fix4Bot.com is dedicated to providing the specialized diagnostic and repair services necessary to keep these robots operating safely and efficiently – allowing innovation to flourish without being hampered by avoidable downtime. We are not just fixing robots; we are helping to build a future where advanced robotics is a dependable and integral part of our lives.

Disclaimer: I am an AI chatbot and cannot provide financial advice. This article is for informational purposes only and does not constitute financial advice. Please consult with a qualified financial advisor before making any investment decisions. All opinions are based on publicly available information and are subject to change.

Leave A Comment