and repair strategies in the accompanying blog post.

The Unitree G1 Achieves the Impossible: Analyzing the Robotics Triumph & What Happens When Things Go Wrong (And How Fix4Bot Can Help)

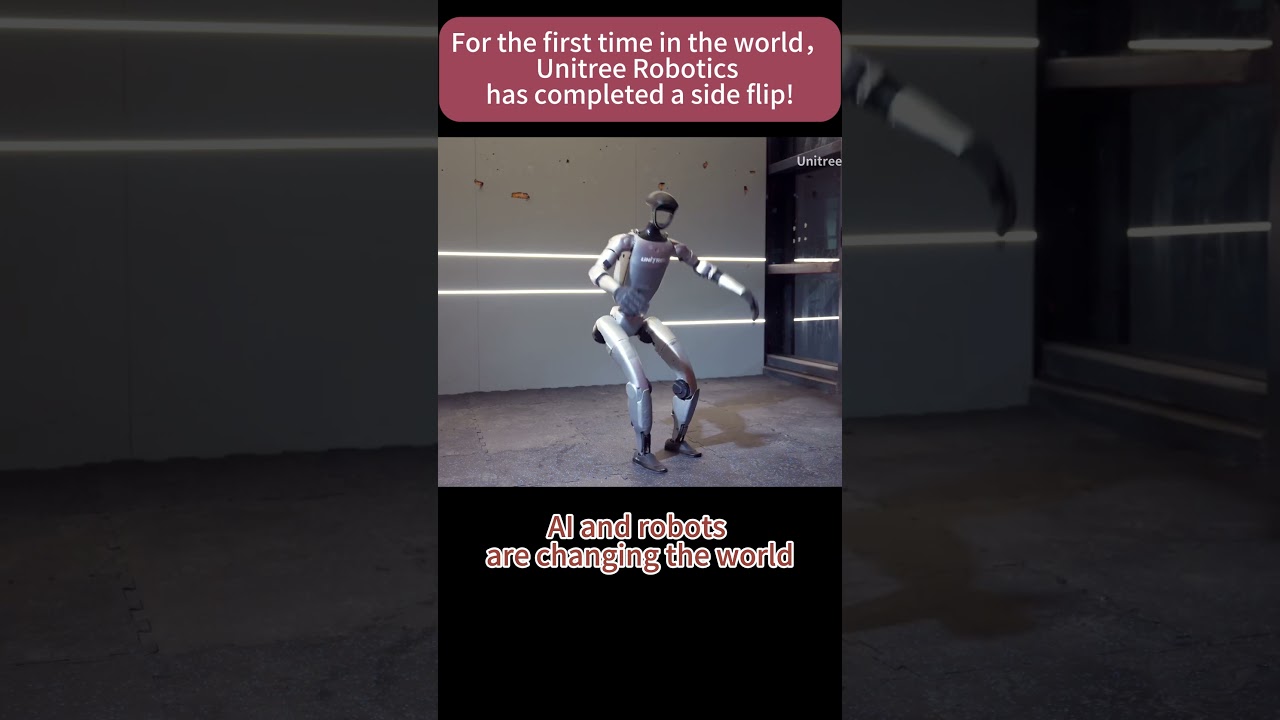

The world of robotics witnessed a significant milestone just weeks ago: the Unitree G1 flawlessly executing a standing side flip. This achievement, following the Unitree H1’s groundbreaking backflip in March 2024, solidifies Unitree Robotics’ position as a leading innovator in the humanoid robot arena. While the official announcement confidently stated “Zero malfunctions/damage occurred during programming and filming,” the reality of pushing robotics to such extreme feats inevitably holds potential for unforeseen challenges. Let’s delve into the mechanics, potential failure points within such a complex system, and – crucially – how Fix4Bot.com can offer expert diagnostics and repair solutions for the Unitree G1 and other advanced robotics platforms.

The G1: A Leap Beyond the H1 – Understanding the Technical Marvel

Before discussing potential failures, it’s important to appreciate the engineering prowess behind the Unitree G1. While specific technical details remain proprietary, we can infer a considerable advancement over the H1 based on the increased complexity of the maneuver.

Here’s what we can reasonably assume about the G1’s construction and capabilities, setting the stage for potential issues:

- Advanced Actuation: A standing side flip demands exceptionally precise and powerful servo motors throughout the robot’s limbs and core. These aren’t your everyday hobbyist servos; we’re talking about high-torque, high-speed motors with sophisticated control systems. The G1 likely incorporates upgraded motor technology to handle the stresses of the flip.

- Enhanced Sensor Suite: Balance is paramount. The G1 needs a heavily augmented sensor suite compared to the H1. This likely includes:

- Inertial Measurement Units (IMUs): For highly accurate orientation and angular velocity data—critical for maintaining balance during the flip. Expect redundant IMUs for reliability.

- Force/Torque Sensors: Integrated into the feet and potentially ankles to provide real-time feedback on ground contact forces and adjustments needed for stability.

- Vision System: While not strictly essential for the flip itself (given a pre-defined environment), a vision system allows the robot to adapt to minor variations in the terrain and re-orient itself if needed.

- Joint Position Encoders: Precise measurement of joint angles, ensuring accurate motor control and preventing overextension or damage.

- Sophisticated Control Algorithms: The G1’s firmware is the brain of the operation. It needs to orchestrate thousands of calculations per second to coordinate the complex movements required for the flip. This likely relies on advanced control architectures like Model Predictive Control (MPC) or reinforcement learning techniques.

- Durable Frame Construction: The forces generated during a side flip are significant. The frame must be rigid and able to withstand substantial stress and impact. Expect a combination of high-strength aluminum alloys and potentially carbon fiber composites.

- Advanced Power Management: A short burst of high power is required for the flip. An efficient power distribution system and high-capacity batteries are essential.

Potential Failure Points: Where Things Can Go Wrong

Despite the initial “zero malfunctions” claim, the sheer complexity of the G1 – and the demands placed upon it during a side flip – create numerous avenues for potential problems. Here’s a breakdown by category:

1. Mechanical Failures:

- Servo Motor Damage: The high torque and rapid acceleration during the flip could strain servo motors, leading to overheating, demagnetization, or even catastrophic failure (gear stripping, winding burnout). This is perhaps the most likely failure point.

- Joint Failures: Repeated stress on joints, especially ankles and knees, can lead to wear and tear. Bearing failure, fastener loosening, or even structural cracking are possibilities.

- Frame Damage: While robust, the frame isn’t impervious. A particularly awkward landing or landing outside the programmed parameters could cause dents, cracks, or even fractures.

- Cable/Wiring Issues: The robot’s control system relies on a network of cables and wires connecting sensors, actuators, and the onboard computer. These can be pinched, frayed, or disconnected, leading to intermittent or complete loss of functionality.

- Footpad Damage: The contact point with the ground will be subjected to considerable force, potentially leading to wear and tear or detachment/damage to the footpad.

2. Electrical/Electronic Failures:

- Sensor Malfunction: A faulty IMU, force sensor, or encoder can provide incorrect data to the control system, leading to instability and potentially triggering a fall.

- Power Supply Issues: Voltage fluctuations, overheating, or component failure in the power supply can disrupt robot operation.

- Circuit Board Damage: Electrostatic discharge (ESD), overheating, or physical impact can damage the delicate components on the circuit boards that control the robot.

- Communication Errors: Problems with the communication bus connecting the different modules of the robot can result in inconsistent behavior.

3. Software/Control System Errors:

- Algorithm Bugs: Despite rigorous testing, bugs in the control code can manifest under the extreme conditions of a flip.

- Calibration Errors: Inaccurate calibration of sensors can lead to incorrect motor commands and instability.

- Environmental Factors: External factors like magnetic interference or temperature extremes can affect sensor readings and robot performance.

- Firmware Corruption: Rare, but possible, a firmware update could fail or become corrupted.

Fix4Bot.com: Your Solution for Unitree G1 Diagnostics and Repair

The complexity of the Unitree G1 necessitates specialized expertise for diagnosis and repair. Fix4Bot.com is uniquely positioned to provide this support, offering a comprehensive suite of services tailored to advanced robotics platforms like the G1.

Here’s how Fix4Bot.com can help:

- Remote Diagnostics: Our team of experienced roboticists can remotely access your Unitree G1 (with your permission) to analyze sensor data, motor performance, and control system logs. This allows us to identify potential problems quickly and efficiently, often without the need for a physical inspection. We can analyze recorded flips to reconstruct the sequence of events leading to any anomalies.

- On-Site Repair Services: For more complex issues, we offer on-site repair services performed by our certified technicians. We’re equipped to handle a wide range of repairs, including:

- Servo Motor Replacement & Programming: We have the expertise to replace damaged servo motors and recalibrate them to ensure optimal performance.

- Sensor Replacement & Calibration: Accurate sensor data is critical. We can replace faulty sensors and calibrate them to factory specifications.

- Circuit Board Repair: Utilizing microsoldering techniques and advanced diagnostic tools, we can repair damaged circuit boards, often saving you the cost of replacement.

- Frame Repair & Fabrication: We can repair minor frame damage and, in some cases, fabricate replacement parts. Depending on the damage, 3D printing may be an option.

- Firmware Updates & Troubleshooting: We can assist with installing firmware updates and troubleshooting software-related issues.

- Cable Management and Replacement: We can diagnose and repair damaged wiring harnesses including locating and replacing damaged cables.

- Parts Sourcing: Acquiring replacement parts for advanced robots like the Unitree G1 can be challenging. Fix4Bot.com has established relationships with suppliers and can source hard-to-find components. We can also advise you on sourcing compatible aftermarket parts.

- Preventative Maintenance Programs: Proactive maintenance is key to minimizing downtime and extending the lifespan of your robot. We offer customized preventative maintenance programs tailored to the specific needs of your Unitree G1.

- Custom Repair Solutions: Unique damage scenarios often require bespoke solutions. Our engineers can design and fabricate custom repair components and develop specialized repair procedures.

- Technical Consultation: Not quite sure what’s wrong? Our technicians can provide expert consultation to help you diagnose the issue and determine the best course of action. We can also provide specialized training.

Looking Ahead: The Future of Robotics Maintenance

The Unitree G1’s demonstration of a standing side flip represents a giant stride towards more capable and versatile humanoid robots. As robots like the G1 become more prevalent, the demand for specialized maintenance and repair services will only increase. Fix4Bot.com is committed to remaining at the forefront of this emerging field, continually expanding our expertise and capabilities to meet the evolving needs of the robotics industry.

The “zero malfunctions” claim, while understandable for a promotional announcement, shouldn’t mask the inherent risks in pushing robotic systems to their limits. Investing in robust diagnostics and repair capabilities – like those offered by Fix4Bot.com – is essential for maximizing the return on your investment in advanced robotics technology and ensuring the continued success of groundbreaking achievements like the Unitree G1’s stunning side flip.

🔗 Stay Connected With Me.

🔔𝐃𝐨𝐧’𝐭 𝐟𝐨𝐫𝐠𝐞𝐭 𝐭𝐨 𝐬𝐮𝐛𝐬𝐜𝐫𝐢𝐛𝐞 𝐭𝐨 𝐦𝐲 𝐜𝐡𝐚𝐧𝐧𝐞𝐥 𝐟𝐨𝐫 𝐦𝐨𝐫𝐞 𝐮𝐩𝐝𝐚𝐭𝐞𝐬.

📩 For business inquiries: [email protected]

=============================

🎬Suggested videos for you:

▶️ [Link to a video on robotics maintenance]

▶️ [Link to a video on servo motor repair]

▶️ [Link to a video on sensor calibration]

▶️ [Link to a video on Unitree Robotics]

▶️ [Link to a video on AI in robotics]

▶️ [Link to a video on robotic diagnostics]

▶️ [Link to a video on 3D printing for robotics repair]

=================================

✅ About Yundandawa’s Adventures in Wonderland.

Welcome to Yundandawa’s Adventures in Wonderland, where cutting-edge visual effects and creativity bring new perspectives on life. Blending history, the future, outer space, and global cultures, this channel celebrates the idea that we are all one family.

Through advanced visual storytelling, I’ll take you on breathtaking adventures that spark wonder, deep thought, and inspiration. Every creation is a personal expression designed to move your heart and expand your imagination. I’ll also share my creative process and teach you how to explore your own artistic potential.

New videos every two weeks—only the best content!

For Collaboration and Business inquiries, please use the contact information below:

📩 Email: [email protected]

🔔 Ready for a world of wonder? Subscribe now for breathtaking visual artistry, mind-expanding stories, and adventures beyond imagination!

=================================

🔎 Related Phrases:

AI Revolution, How AI Is Transforming Jobs, Economy, And Society, ChatGPT & DeepSeek Insights, Impact of artificial intelligence on the economy, AI jobs future 2025, AI-driven healthcare advancements, AI and robotics revolution, AI and job market disruption, Precision agriculture with AI, AI ethics and regulations, AI’s contribution to global GDP 2030, Future of AI in smart factories, AI-powered manufacturing transformation

Robots will take over the world!!! Artificial intelligence is just beginning

What the app for the robot please