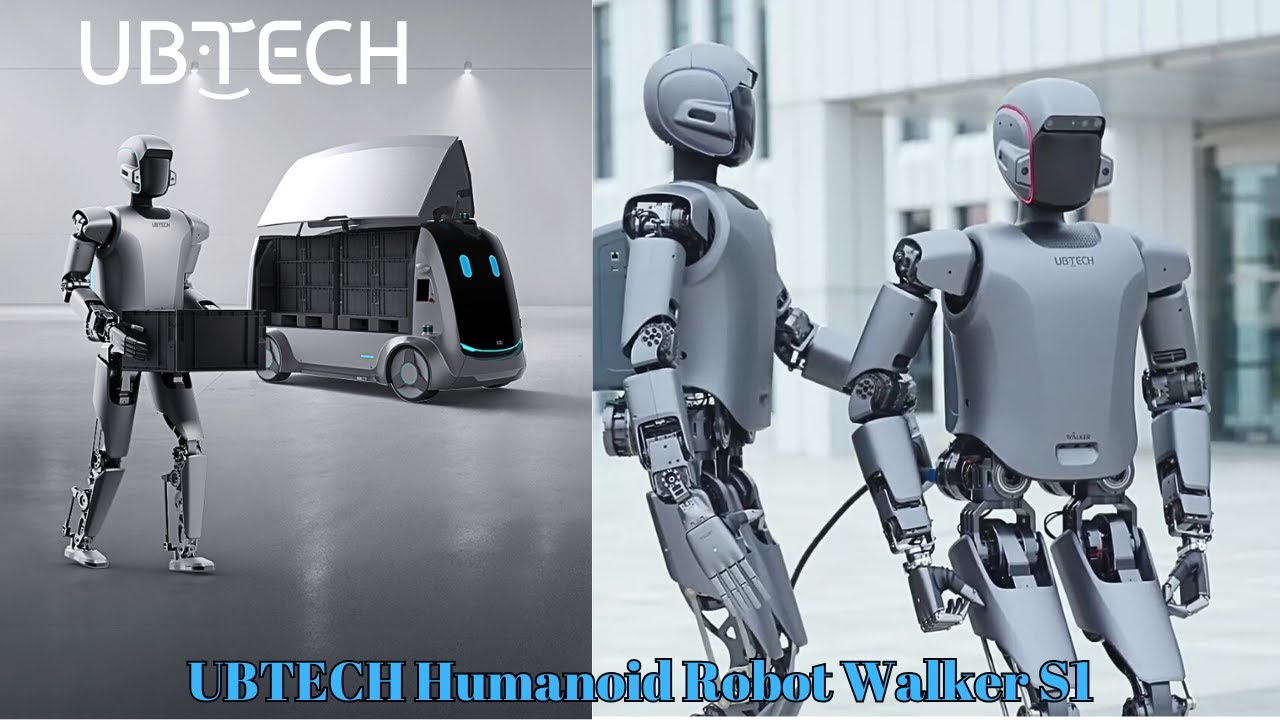

The Walker S1: Diagnosing and Repairing Advanced Humanoid Robotics – A Fix4Bot.com Guide

The robotics landscape is rapidly evolving, and with it, the complexity of maintaining these sophisticated machines. The Walker S1, a groundbreaking humanoid robot designed for complex industrial environments, represents a significant leap forward. Its capabilities – advanced planning, semantic navigation, dexterous manipulation, and collaborative operation – are pushing the boundaries of what’s possible. However, these very features also introduce new and intricate challenges when it comes to diagnostics and repair. At Fix4Bot.com, we specialize in providing solutions for robotic system maintenance and issue resolution. This article offers a comprehensive overview of potential damages and the repair methodologies we employ to keep the Walker S1 performing at its peak.

Understanding the Walker S1’s Core Strengths – and Potential Weak Points

Before diving into specific repair scenarios, it’s crucial to understand the core technologies that define the Walker S1. Its advanced functionality stems from a convergence of several key innovations, each representing a potential point of failure:

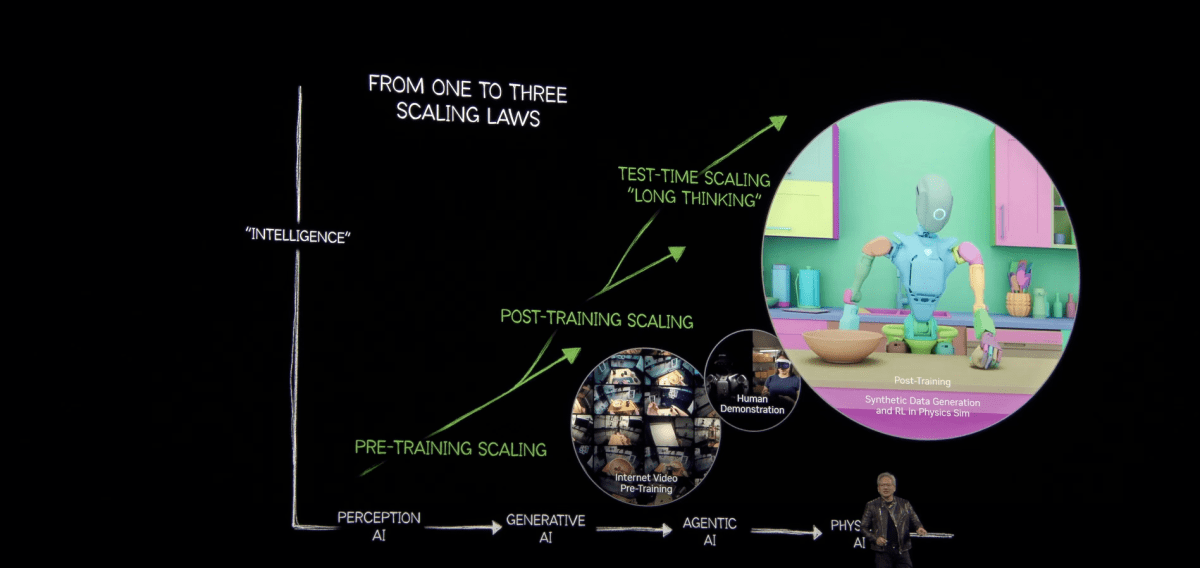

- Large Multi-Modal Planning Model for General Tasks: This is the brain of the operation, responsible for understanding complex goals, breaking them down into actionable steps, and adapting to unforeseen circumstances. Its reliance on both simulation and real-world data makes it susceptible to corruption and inconsistencies.

- Semantic VSLAM Navigation: The simultaneous localization and mapping (SLAM) system forms the basis for navigation, but the integration of semantic perception adds layers of complexity – and potential failure points. The ‘coarse-fine’ approach necessitates precise calibration and robust data fusion.

- End-to-End Learning Full-Body Motion Control Framework: This framework allows for dexterous operation and stable walking. The "end-to-end" nature means a fault at any point in the pipeline can cascade through the entire control system.

- Collaborative Operation Capability: Designed to work seamlessly with automated guided vehicles (AGVs), forklifts, and production management systems, this feature introduces complexities related to communication protocols, data synchronization, and inter-system dependencies.

Categorizing Potential Damages and Failures

To effectively address potential issues, we’ve categorized them into hardware, software, and integration-related failures.

1. Hardware Failures:

- Actuator Degradation/Failure: Humanoid robots rely on numerous actuators (motors, hydraulics, pneumatics) for movement. Wear and tear, overloading, or environmental factors (dust, temperature) can lead to degradation and eventual failure. Symptoms: Jerky movements, decreased range of motion, inability to perform specific actions, unusual noises. Fix4Bot.com Approach: Non-destructive testing to assess actuator health, replacement of faulty actuators (with genuine or approved OEM parts), dynamic calibration after replacement. Predictive maintenance leveraging vibration analysis and thermal imaging to identify signs of impending failure.

- Sensor Malfunction (Cameras, LiDAR, IMUs): The Walker S1’s sensing suite is critical for perception and navigation. Damage from impacts, electromagnetic interference, or inherent sensor drift can significantly impact performance. Symptoms: Navigation errors, inaccurate object recognition, unstable movement, inability to map the environment. Fix4Bot.com Approach: Sensor calibration procedures utilizing specialized equipment, replacement of faulty sensors, implementation of sensor fusion algorithms to mitigate noise and drift (where possible). Analysis of sensor data logs to identify patterns indicating degradation.

- Structural Damage: Collisions, falls, or excessive loads can damage the robot’s frame or joints. Symptoms: Visible cracks or deformations, instability, restricted movement, unusual noises. Fix4Bot.com Approach: Non-destructive testing (NDT) using techniques like ultrasonic testing and X-ray imaging to identify hidden cracks. Repair using epoxy bonding, welding (where appropriate and structurally sound), or replacement of damaged components. Finite Element Analysis (FEA) to determine load-bearing capacity after repair.

- Battery Degradation: While not immediately apparent, battery life diminishing over time is a common issue. Symptoms: Reduced operational time, erratic power delivery, system shutdowns. Fix4Bot.com Approach: Battery health assessment using specialized diagnostic tools which checks for internal resistance, capacity and voltage stability. Replacement with new, approved batteries, implementing optimal charging protocols to extend battery life.

2. Software Failures:

- Multi-Modal Planning Model Corruption: The core planning model, trained on vast datasets, is susceptible to corruption due to data storage errors, software bugs, or malicious attacks. Symptoms: The robot failing to understand tasks, generating illogical plans, or displaying unpredictable behavior. Fix4Bot.com Approach: Version control rollback to a known stable model, data integrity checks of training datasets, debugging the planning algorithms, and retraining the model on clean data. Using anomaly detection techniques to identify deviations from expected behavior.

- VSLAM Algorithm Errors: Issues in the semantic VSLAM algorithm can lead to inaccurate maps or localization errors. Symptoms: The robot getting lost, colliding with objects, or exhibiting jerky movements. Fix4Bot.com Approach: Recalibrating the VSLAM parameters, optimizing the feature extraction and matching algorithms, evaluating the performance of the semantic segmentation component, and checking for data synchronization issues between sensors. Implementing robust error handling mechanisms to gracefully recover from localization failures.

- Motion Control System Instability: Bugs in the end-to-end learning framework can lead to unstable walking, inaccurate movements, or even complete system lockups. Symptoms: Uncontrolled movements, erratic behavior, inability to complete tasks, system crashes. Fix4Bot.com Approach: Debugging the control algorithms using simulation environments, analyzing sensor data and control signals to identify patterns leading to instability, implementing robust control strategies to compensate for disturbances, and utilizing reinforcement learning techniques to fine-tune the control parameters.

- Communication Protocol Issues: Problems with communication between the Walker S1 and external systems (AGVs, production management systems) can disrupt operations. Symptoms: Failure to receive task commands, inability to share data, synchronization errors. Fix4Bot.com Approach: Analyzing network logs to identify communication errors, verifying the integrity of communication protocols, implementing error handling mechanisms to gracefully deal with communication failures, and ensuring compatibility between the Walker S1 and external systems.

3. Integration-Related Failures:

- AGV/Forklift Synchronization Problems: The collaborative nature of the Walker S1 demands seamless synchronization with accompanying vehicles. Timing discrepancies or data conflicts can lead to collisions or operational inefficiencies. Symptoms: The robot anticipating AGV/Forklift movements incorrectly, leading to near collisions or blocked pathways. Fix4Bot.com Approach: Implementing robust synchronization protocols, using real-time data fusion techniques to combine sensor data from both the robot and the vehicles, and optimizing the communication bandwidth between systems. Employing fail-safe mechanisms to halt operations in case of synchronization failures.

- Environmental Interference: The industrial environment presents challenges like dust, electromagnetic interference, and dynamic lighting. These factors can affect sensor performance and overall robustness. Symptoms: Reduced sensor accuracy, navigation errors, unreliable object recognition. Fix4Bot.com Approach: Implementing environmental shielding for sensitive components, using robust sensor cleaning protocols, and incorporating adaptive algorithms that can compensate for changing environmental conditions.

- Human-Robot Interaction (HRI) Issues: Safe and effective HRI is essential. Misunderstanding human commands or reacting unexpectedly can lead to safety hazards. Symptoms: The robot failing to respond to commands correctly, exhibiting unexpected movements, or posing a potential safety risk. Fix4Bot.com Approach: Improving the natural language processing capabilities of the robot, implementing robust safety protocols, and using haptic feedback systems to provide clear communication between the robot and humans.

Fix4Bot.com’s Diagnostic and Repair Toolkit:

Addressing the complexities of the Walker S1 requires a combination of advanced tools and specialized expertise. At Fix4Bot.com, we use:

- Advanced Diagnostic Software: proprietary software capable of interfacing with the Walker S1’s internal systems, extracting diagnostic data, and analyzing system logs.

- Robotic Calibration Equipment: Precision laser trackers, motion capture systems, and force/torque sensors to ensure accurate calibration of sensors and actuators.

- Simulation Environments: Replicating real-world conditions to test repair strategies and train the robot’s AI.

- Non-Destructive Testing (NDT) Equipment: Ultrasound, X-ray, and thermography tools for assessing structural integrity without damaging the robot.

- Spare Parts Inventory: A comprehensive inventory of genuine and approved OEM parts.

- Expert Robotics Engineers: A team of experienced engineers specializing in humanoid robotics, software development, and mechanical engineering.

Proactive Maintenance & Future-Proofing

Preventative maintenance is key to minimizing downtime and extending the lifespan of the Walker S1. We recommend:

- Regular Sensor Calibration: Following the manufacturer’s recommended calibration schedule.

- Actuator Inspection and Lubrication: Detecting early signs of wear and tear.

- Software Updates: Installing the latest software updates to benefit from bug fixes and performance improvements.

- Data Logging and Analysis: Continuously monitoring system performance and identifying potential issues before they escalate.

- Remote Monitoring Services: Fix4Bot.com offers remote monitoring and diagnostic services to proactively address potential problems.

The Walker S1 represents a substantial investment. With the right diagnostic and repair capabilities, its potential can be fully realized. Fix4Bot.com is committed to providing the expertise and support needed to keep this groundbreaking robot operating reliably and efficiently, ensuring its continued success in complex industrial environments. Contact us today to learn more about our services.

Leave A Comment