The T170A Humanoid Robot: Diagnosing and Repairing the Future of Mobility

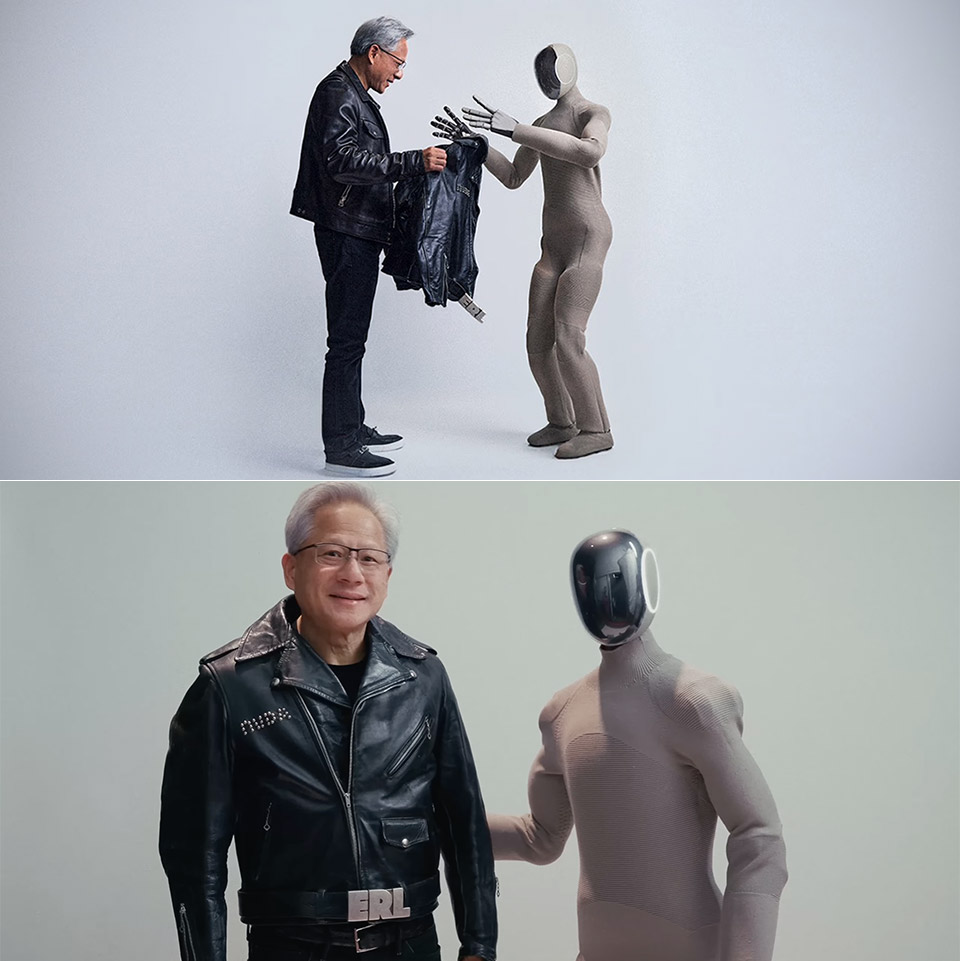

The emergence of sophisticated humanoid robots like the T170A represents a significant leap in robotics technology. At 170 cm tall, weighing 50 kg, and boasting an impressive 44 degrees of freedom, this bipedal bot – powered by a high-performance NVIDIA Jetson AGX Orin 64GB and featuring a robust payload capacity and exceptional torque – is poised to revolutionize numerous fields, from logistics and healthcare to exploration and entertainment. However, with such complex machinery comes an inevitable need for diagnostic and repair services. This is where Fix4Bot.com steps in, offering comprehensive solutions for maintaining and restoring the T170A and similar advanced robots to peak performance.

This article explores the potential damage scenarios the T170A might encounter, the diagnostic approaches Fix4Bot.com employs, and the specialized repair techniques utilized to address these challenges. We’ll delve into the intricacies of its mechanical, electrical, and software components, outlining the expertise required to keep this impressive robot operational.

Understanding the T170A’s Key Systems and Potential Failure Points

Before diving into diagnostics and repairs, it’s crucial to understand the T170A’s core systems and the potential vulnerabilities within each.

- Mechanical Systems (Actuators, Joints, and Frame): The T170A’s mobility—particularly its ability to perform single-leg jumps thanks to 220 Nm/kg torque in the leg joints—relies on a complex network of actuators (motors and gearboxes), precision joints, and a robust frame. Potential issues range from actuator failure due to excessive strain or wear to joint misalignment caused by impacts or uneven terrain. Frame damage, while less common, can occur in situations involving significant collisions or overload. Further, lubrication and maintenance of the joints is vital to prevent seizing and friction build-up.

- Electrical Systems (Power Supply, Wiring, and Sensors): The robot’s power supply, responsible for delivering consistent energy to all components, is susceptible to failure due to voltage fluctuations, overheating, or component breakdown. Wiring harnesses, particularly those within the limbs, are vulnerable to fraying, shorts, or disconnection due to repetitive movement. The array of sensors—including binocular vision and LiDAR—can experience damage from dust, scratches, misalignment, or internal component failure.

- Computational System (NVIDIA Jetson AGX Orin): The NVIDIA Jetson AGX Orin 64GB forms the brain of the T170A, responsible for processing sensor data, executing control algorithms, and managing overall robot behavior. Potential issues include software glitches, corrupted data, overheating, or hardware failures within the Orin module itself.

- Perception and Navigation Systems (Binocular Vision & LiDAR): The binocular vision system allows the robot to understand its environment through image processing and object recognition. The LiDAR system creates a 3D map of the surroundings. Damage, calibration errors, and interference can degrade the accuracy and reliability of these systems, significantly impacting the robot’s navigation and interaction capabilities.

- Software & Control Systems: The firmware and control algorithms governing the T170A’s movements and actions are vital. Bugs, corrupted files, or outdated software can lead to erratic behavior, instability, and even complete system failure.

Fix4Bot.com’s Diagnostic Approach: A Multi-Tiered Strategy

Fix4Bot.com utilizes a comprehensive, tiered diagnostic approach to identify and isolate problems within the T170A.

- Tier 1: Preliminary Visual Inspection and Functional Testing: The process always begins with a thorough visual inspection of the robot, looking for obvious signs of damage – cracks in the frame, frayed wires, loose connections, or sensor obstructions. Following this, basic functional tests are performed, including range of motion checks for each joint, power-up verification, and simple movement commands. This layer often identifies easily resolvable issues.

- Tier 2: Advanced System Diagnostics: If the preliminary inspection fails to pinpoint the problem, more sophisticated diagnostics are employed.

- Actuator Diagnostics: Special tools are used to measure actuator current draw, voltage, and temperature, identifying anomalies that might indicate wear or impending failure. We can also test for "cogging" (unnecessary resistance in the motor) and vibration analysis.

- Electrical Circuit Testing: Using multi-meters and circuit testers, we methodically trace electrical signals throughout the robot’s wiring harness, looking for shorts, opens, and voltage drops. Thermal imaging is employed to identify hotspots indicative of overloaded components.

- Sensor Calibration and Validation: The binocular vision and LiDAR systems undergo rigorous calibration procedures. Fix4Bot.com uses specialized software and targets to ensure accurate depth perception and environmental mapping. Data from these sensors are compared against known reference points to identify drift or inaccuracies.

- Software & Log File Analysis: We analyze the robot’s system logs for error messages, warnings, and unusual events that can provide clues about software glitches or hardware issues. We use debugging tools to step through the control algorithms and identify the source of problems.

- Tier 3: In-Depth Hardware Analysis & Simulation: For complex or elusive issues, we delve into hardware-level diagnostics.

- NVIDIA Jetson AGX Orin Diagnostic: We utilize NVIDIA’s diagnostic tools to test memory integrity, processing speed, and overall system stability. If necessary, we can perform hardware replacements within the module itself, utilizing specialized micro-soldering techniques.

- Finite Element Analysis (FEA): For suspected frame or component failures, FEA simulations are used to analyze stress distributions under various load conditions. This helps identify weak points and potential failure mechanisms.

- Reverse Engineering & Code Analysis: In cases involving software malfunctions, we may engage in reverse engineering of the control code to identify bugs or vulnerabilities.

Repair Techniques & Solutions at Fix4Bot.com

Once a problem is diagnosed, Fix4Bot.com implements targeted repair solutions, leveraging a variety of specialized techniques:

- Mechanical Repairs:

- Joint Rebuilds: Worn or damaged joints are disassembled, cleaned, lubricated, and rebuilt with replacement bearings, gears, and seals.

- Frame Welding & Fabrication: Minor frame cracks or breaks are repaired through precise welding techniques. More extensive damage might require custom fabrication of replacement frame components.

- Actuator Replacement & Calibration: Faulty actuators are replaced with new or refurbished units. Following replacement, actuators are meticulously calibrated to ensure accurate and synchronized movement.

- Electrical Repairs:

- Wiring Harness Repair & Replacement: Frayed or damaged wires are meticulously repaired using specialized soldering techniques. Entire wiring harnesses are replaced if the damage is extensive.

- Component Level Repair: Using micro-soldering and reflow ovens, we repair or replace individual electronic components on circuit boards, including power regulators, MOSFETs, and sensors.

- Power Supply Replacement: Faulty power supplies are replaced with compatible units. We verify the new power supply’s voltage and current output to ensure proper functionality.

- Software & Firmware Updates:

- Bug Fixes & Patches: We apply vendor-supplied bug fixes and patches to address known software vulnerabilities.

- Custom Software Development: In cases where custom functionality is required or existing software is inadequate, we can develop custom firmware and control algorithms.

- System Reimaging: If the operating system is corrupted, we can perform a "clean" reimaging of the NVIDIA Jetson AGX Orin, restoring the system to its factory default state.

- Perception System Restoration:

- Sensor Cleaning and Alignment: Binocular cameras and LiDAR units are carefully cleaned to remove dust and debris. Precise alignment procedures are utilized to ensure accurate data acquisition.

- Software Calibration: Software calibration routines are run to compensate for minor sensor imperfections or drift.

Challenges and Future Trends

Repairing and maintaining advanced humanoid robots like the T170A presents unique challenges. The complexity of the integrated systems, the high cost of replacement parts, and the need for specialized expertise demand a proactive and preventative maintenance approach.

Looking ahead, we anticipate several key trends impacting robotic repair:

- Increased Component Standardization: The rise of modular robotic designs, using standardized components, will simplify repairs and reduce downtime.

- AI-Powered Diagnostics: Artificial intelligence will play an increasingly important role in automating diagnostic processes, enabling faster and more accurate problem identification.

- Remote Diagnostics & Repair: The ability to remotely diagnose and even perform minor repairs through teleoperation will become more commonplace.

- Predictive Maintenance: Data analytics and machine learning will be used to predict potential failures, allowing for proactive maintenance and preventing costly breakdowns.

Conclusion

The T170A Humanoid Robot represents a significant technological achievement. Maintaining and repairing these sophisticated robots requires a deep understanding of their intricate mechanical, electrical, and software systems. Fix4Bot.com is dedicated to providing comprehensive diagnostic and repair services for the T170A and other advanced robots, ensuring they remain operational and driving innovation across various industries. By combining experienced technicians, advanced diagnostic tools, and a commitment to quality, Fix4Bot.com is at the forefront of robotic repair, helping shape the future of humanoid robotics.

[Follow us: Facebook: [Insert Facebook Link], YouTube: [Insert YouTube Link], TikTok: [Insert TikTok Link], Instagram: [Insert Instagram Link], LinkedIn: [Insert LinkedIn Link], Twitter: [Insert Twitter Link]]

Leave A Comment