## Keeping the Revolution Rolling: Fix4Bot.com – Your Expert Partner in Maintaining and Repairing Dexterity’s Mech Super-Humanoid Robot

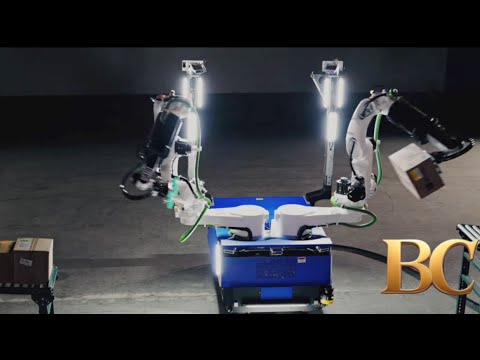

The dawn of industrial super-humanoid robotics is upon us, and at the forefront of this transformative wave stands Dexterity’s Mech. This groundbreaking creation, a marvel of engineering and artificial intelligence, is poised to redefine enterprise operations across industries. Mech, a rover-mounted behemoth boasting dual arms with an expansive 5.4-meter wingspan and the capacity to lift up to 132 pounds, is not just a robot; it’s a paradigm shift. Designed to tackle the most demanding warehouse tasks – from the relentless loading and unloading of trucks to the intricate art of palletizing and maneuvering within the confines of tight spaces – Mech is a testament to human ingenuity and our relentless pursuit of efficiency and innovation.

Powered by a sophisticated blend of Physical AI and a formidable supercomputer, Mech’s capabilities extend far beyond pre-programmed tasks. Its adaptability allows it to learn and execute new operations with remarkable ease, even something as seemingly simple yet symbolically significant as installing a new application – a feat that speaks volumes about its advanced cognitive and motor skills. Equipped with a network of up to 16 cameras and a highly refined sense of touch, Mech is not only enhancing operational efficiency but also contributing to safer work environments by demonstrably reducing workplace injuries, as highlighted by reports from leading technology publications like Interesting Engineering.

Scale and cloud connectivity further amplify Mech’s revolutionary potential, solidifying its position as a monumental leap forward in industrial automation and logistics. This is not just about automating existing processes; it is about fundamentally reimagining how we approach work, productivity, and the synergy between human capabilities and robotic assistance.

However, with such groundbreaking technological advancements comes a critical, often overlooked, imperative: maintenance and repair. Just as a high-performance race car requires a team of expert mechanics to ensure it remains in peak condition, so too does Dexterity’s Mech, and other sophisticated industrial robots, demand specialized care to guarantee its continued operational excellence and prevent costly downtime. This is where Fix4Bot.com steps into the spotlight – not just as a repair service, but as an essential partner in ensuring the longevity, reliability, and sustained revolutionary impact of industrial robots like Mech.

Fix4Bot.com is not your average robotics repair shop. We are a dedicated hub of expertise specifically engineered to diagnose, repair, and maintain the most advanced industrial robots on the market, with a specialized focus on complex systems like Mech. Our mission is singular: to ensure that the promise of super-humanoid robotics is fully realized, unimpeded by downtime or compromised by inadequate maintenance. We understand that these robots are not mere machines; they are complex ecosystems of mechanical, electrical, software, and AI components working in intricate harmony. Repairing them demands a holistic understanding and a level of expertise that goes far beyond traditional industrial maintenance.

This blog article delves deep into how Fix4Bot.com stands uniquely equipped to diagnose and repair any damages to Dexterity’s Mech, ensuring that this marvel of engineering continues to revolutionize industries and shape the future of work. We will explore the sophisticated methodologies, cutting-edge technologies, and unparalleled expertise that position Fix4Bot.com as the premier solution for maintaining the vanguard of industrial automation.

### Understanding the Delicate Complexity of Mech: Why Expert Repair is Non-Negotiable

Dexterity’s Mech is more than just a collection of gears, wires, and algorithms; it’s a meticulously orchestrated symphony of advanced technologies. Its robust rover base provides mobility and stability, while its dual arms, with their impressive wingspan and lifting capacity, represent a pinnacle of robotic dexterity and strength. These are not simply robotic arms; they are highly articulated, sensor-laden appendages capable of performing intricate tasks with precision and force.

The heart of Mech lies in its Physical AI and supercomputer. This is not just software; it’s a sophisticated cognitive architecture that allows Mech to learn, adapt, and execute complex tasks beyond pre-programmed routines. The AI component enables Mech to understand its environment, make real-time decisions, and refine its performance continuously. The supercomputer provides the processing power necessary to handle the vast amounts of data generated by its senses and to execute the complex computations required for its advanced AI algorithms to function effectively.

Integrated into this intricate mechanical and computational framework is a comprehensive sensor suite, headlined by up to 16 cameras and a refined sense of touch. These sensors are not just for show; they are the robot’s eyes and hands, providing it with a rich understanding of its surroundings and enabling it to interact with objects and environments in a nuanced and responsive manner. The cameras provide visual input for object recognition, navigation, and task execution, while the touch sensors offer tactile feedback, allowing Mech to perform delicate tasks with precision and avoid damaging objects.

This complexity underscores a critical point: repairing Mech is not akin to fixing conventional industrial machinery. It requires a specialized skillset, in-depth knowledge of robotics, AI, and sensor technologies, and access to advanced diagnostic and repair tools. Attempting to repair Mech with generic industrial maintenance procedures or by technicians lacking specific robotics expertise is not only inefficient but also potentially damaging. Improper repairs can lead to further malfunctions, reduced performance, compromised safety, and ultimately, significant financial losses through extended downtime and decreased productivity.

Fix4Bot.com recognizes this inherent complexity and has built its entire service model around the principle of specialized expertise. Our technicians are not just mechanics; they are robotics engineers, AI specialists, and sensor technology experts, trained specifically to understand the intricate workings of advanced industrial robots like Mech. We understand that each component – from the actuators in its arms to the algorithms in its AI core – plays a crucial role in the robot’s overall performance, and that effective repair requires a holistic approach that addresses the root cause of any issue at a system level.

### Fix4Bot.com: The Pioneers of Industrial Robotics Repair

Fix4Bot.com is not a newcomer to the field of robotics; we are pioneers. Born from a deep understanding of the burgeoning industrial robotics landscape and the critical need for specialized repair and maintenance services, Fix4Bot.com was established to be the trusted partner for businesses embracing the future of automation. We are more than just a repair service; we are a dedicated ecosystem designed to support the entire lifecycle of advanced industrial robots, ensuring they operate at peak performance, minimize downtime, and deliver on their promised revolutionary potential.

Our facilities are not generic workshops; they are state-of-the-art robotics repair centers, specifically designed and equipped to handle the most complex diagnostic and repair procedures. We have invested heavily in cutting-edge diagnostic tools, including robotic arm calibration systems, advanced sensor testing equipment, AI debugging tools, and non-destructive testing technologies. Our workshops are meticulously organized and equipped with specialized tooling and equipment necessary for handling the delicate components of robots like Mech.

Our technicians are not generalists; they are highly specialized experts, each with deep domain knowledge in specific areas of robotics. We employ mechanical engineers with expertise in robotics kinematics and dynamics, electrical engineers specializing in advanced robotic control systems, software engineers with backgrounds in AI and machine learning, and sensor technology specialists proficient in optical, tactile, and proximity sensing systems. Our training programs are rigorous and ongoing, ensuring that our technicians stay at the forefront of robotics technology and are constantly updated on the latest advancements and repair techniques.

At Fix4Bot.com, we understand that downtime is the enemy of productivity. We are committed to providing rapid response and efficient repair services to minimize disruption to our clients’ operations. Our service model is built around speed, efficiency, and transparency. From initial diagnostics to final repair and testing, we keep our clients informed every step of the way, providing clear timelines and cost estimates. Our goal is not just to fix the immediate problem but to provide a comprehensive solution that addresses the root cause of the issue and prevents future occurrences.

We are not just fixing robots; we are enabling the revolution. We understand that the success of industrial robotics depends not only on their initial deployment but also on their long-term reliability and maintainability. Fix4Bot.com is committed to being the cornerstone of this reliability, ensuring that robots like Mech can continue to transform industries for years to come.

### Diagnosing the Intricacies: Fix4Bot.com’s Advanced Diagnostic Arsenal

Diagnosing damages in a robot as sophisticated as Dexterity’s Mech requires a multi-faceted and systematic approach. At Fix4Bot.com, we employ a rigorous diagnostic process that leverages a combination of advanced technology, expert knowledge, and meticulous inspection to pinpoint the exact nature and location of any fault. Our diagnostic arsenal is designed to dissect the robot into its core systems – mechanical, electrical, software/AI, and sensor – and to meticulously examine each component for potential issues.

**Mechanical System Diagnostics:**

The mechanical system of Mech, comprising its rover base, dual arms, joints, actuators, and structural framework, is subject to wear and tear from continuous operation, especially in demanding industrial environments. Potential damages can range from joint wear and tear, actuator failures, gear damage, structural stress fractures, to issues with the mobility system including wheel or motor malfunctions.

Fix4Bot.com utilizes a range of advanced diagnostic tools to assess the mechanical integrity of Mech:

* **Visual Inspection with High-Resolution Imaging:** Our technicians conduct thorough visual inspections, using high-resolution cameras and borescopes to examine joints, linkages, and structural components for signs of wear, damage, or misalignment that might not be visible to the naked eye.

* **Robotic Arm Calibration and Kinematic Analysis Systems:** We employ specialized calibration systems to measure the accuracy and repeatability of Mech’s arm movements. Deviations from factory specifications can indicate joint wear, actuator issues, or kinematic chain misalignments. Software tools then analyze the kinematic data to pinpoint the source of any inaccuracies.

* **Stress and Strain Sensors for Structural Integrity Assessment:** For suspected structural damage, we utilize non-invasive stress and strain sensors to map stress distribution across critical structural members. This allows us to identify areas of excessive strain or potential structural weaknesses.

* **Non-Destructive Testing (NDT) Techniques:** For more in-depth structural analysis, we employ NDT techniques such as ultrasonic testing and dye penetrant inspection to detect subsurface cracks, voids, or material fatigue in critical components without causing any damage.

* **Acoustic Emission Testing for Bearing and Gear Diagnostics:** Acoustic emission sensors can detect minute sounds generated by bearings and gears under stress, providing early warning signs of wear or damage before catastrophic failure occurs.

* **Laser Measurement and Alignment Systems:** Precision laser measurement systems are used to verify the alignment of structural components, arm linkages, and joints, ensuring that the robot’s geometry is within factory specifications.

**Electrical System Diagnostics:**

The electrical system of Mech, encompassing its power distribution network, motor drives, control circuitry, and communication buses, is crucial for its operation. Potential electrical issues include wiring faults, short circuits, power supply malfunctions, motor failures, sensor signal degradation, and communication network interruptions.

Fix4Bot.com employs a suite of sophisticated electrical diagnostic tools:

* **Multimeters and Oscilloscopes for Circuit Analysis:** Our technicians use advanced multimeters and oscilloscopes to measure voltage, current, and signal waveforms at various points in the electrical circuits. This allows us to identify short circuits, open circuits, voltage drops, and signal distortions.

* **Thermal Imaging Cameras for Heat Signature Analysis:** Thermal imaging cameras are used to detect hotspots caused by electrical resistance, overloaded components, or failing connections. This allows us to pinpoint overheating components before they fail completely.

* **Circuit Analysis and Simulation Software:** We utilize circuit analysis software to simulate electrical circuits and compare measured values against expected performance. This helps to isolate faults in complex circuits and identify component-level failures.

* **Cable and Wiring Harness Testers:** Specialized cable and wiring harness testers are used to verify the continuity, insulation resistance, and pin-out configurations of wiring harnesses, identifying any wiring faults or connector issues.

* **Logic Analyzers and Protocol Analyzers for Communication Bus Diagnostics:** For diagnosing communication network issues, such as CAN bus or Ethernet problems, we use logic analyzers and protocol analyzers to capture and decode bus signals, identifying communication errors and protocol violations.

* **Motor Testing and Analysis Equipment:** We utilize specialized motor testing equipment to assess motor winding insulation, bearing condition, and overall motor performance. This helps to diagnose motor failures and identify the root cause.

**Software and AI System Diagnostics:**

The software and AI systems of Mech are the brains of the operation, controlling its movements, decision-making, and task execution. Potential software and AI issues include programming errors, software glitches, algorithm malfunctions, data corruption, AI model degradation, and cybersecurity vulnerabilities.

Fix4Bot.com employs a range of advanced software and AI diagnostic techniques:

* **AI Debugging and Monitoring Tools:** We utilize specialized AI debugging tools to trace the execution flow of the robot’s AI algorithms, monitor variable values, and identify logical errors in the code. Real-time performance monitoring dashboards provide insights into the AI system’s performance and resource utilization.

* **Software Logging and Error Analysis:** Comprehensive software logging systems capture detailed information about the robot’s operation, including error messages, warnings, and system events. Our technicians analyze these logs to identify software glitches, runtime errors, and performance bottlenecks.

* **Neural Network Evaluation and Validation Frameworks:** For diagnosing AI model degradation, we use neural network evaluation frameworks to assess the accuracy, precision, and recall of the AI models used by Mech. This helps to identify if the AI models need retraining or recalibration.

* **Software and Firmware Version Control and Integrity Checks:** We maintain strict version control of all software and firmware components and perform integrity checks to ensure that the correct and unmodified versions are running on the robot, preventing issues caused by corrupted or outdated software.

* **Cybersecurity Vulnerability Scanning and Penetration Testing:** To protect against cybersecurity threats, we conduct regular vulnerability scans and penetration testing to identify and address any security weaknesses in the robot’s software and network connectivity.

* **Task Simulation and Performance Benchmarking:** We use task simulation software to recreate operational scenarios and benchmark the robot’s performance against expected levels. This helps to identify performance degradation and pinpoint software or AI related issues that might not be apparent during static diagnostics.

**Sensor System Diagnostics:**

Mech’s sensor systems, including cameras, touch sensors, proximity sensors, and other environmental sensors, are critical for its perception and interaction with the environment. Potential sensor issues include sensor malfunctions, calibration drifts, signal noise, lens contamination, sensor communication errors, and environmental interference.

Fix4Bot.com utilizes specialized sensor diagnostic equipment:

* **Sensor Calibration and Testing Equipment:** We employ specialized calibration equipment to verify the accuracy and linearity of Mech’s sensors. This includes camera calibration targets, tactile sensor calibration jigs, proximity sensor test fixtures, and environmental testing chambers.

* **Signal Analyzers and Data Acquisition Systems:** We use signal analyzers and data acquisition systems to measure and analyze sensor signals, identifying noise, signal degradation, or communication errors.

* **Environmental Testing Chambers for Sensor Performance Verification:** Environmental testing chambers allow us to simulate different environmental conditions, such as varying light levels, temperatures, and humidity, to test sensor performance under diverse operating scenarios.

* **Visual and Tactile Sensor Testing Software:** Specialized software tools are used to analyze camera images and tactile sensor data, identifying issues such as lens distortion, sensor noise, or calibration errors. Tactile feedback mapping tools visualize touch sensor data to verify sensor functionality and sensitivity.

* **Optical Alignment and Cleaning Equipment:** For camera and optical sensors, we utilize precision optical alignment equipment to ensure proper sensor positioning and focus. Specialized lens cleaning equipment and procedures are used to remove dust, debris, or contaminants that can affect sensor performance.

* **Sensor Communication Bus Analyzers:** For sensors that communicate via digital buses like I2C or SPI, we use bus analyzers to monitor communication traffic and identify any sensor communication errors or protocol violations.

By employing this comprehensive diagnostic arsenal, Fix4Bot.com ensures that every aspect of Mech is thoroughly examined, allowing us to accurately pinpoint the root cause of any issue and develop a targeted and effective repair strategy.

### Precision Restoration: Fix4Bot.com’s Repair and Maintenance Expertise

Once a precise diagnosis is established, Fix4Bot.com transitions to the repair and restoration phase with a commitment to precision, quality, and minimizing downtime. Our repair methodologies are system-specific and tailored to the unique complexities of Mech’s various components.

**Mechanical System Repair:**

* **Component Replacement with OEM or Enhanced Alternatives:** For worn or damaged mechanical components such as joints, actuators, gears, bearings, or structural parts, we use genuine OEM replacement parts whenever possible, ensuring compatibility and maintaining the robot’s original design specifications. In cases where enhanced or upgraded components are available and offer improved performance or durability, we offer these as upgrade options.

* **Precision Alignment and Calibration of Robotic Arms and Joints:** Mechanical repairs often involve disassembling and reassembling complex arm linkages and joint mechanisms. After reassembly, our technicians use precision alignment tools and calibration systems to ensure that all components are perfectly aligned and calibrated to factory specifications, guaranteeing accurate and repeatable robot movements.

* **Lubrication System Overhaul and Maintenance:** Proper lubrication is critical for the long-term health of mechanical components. We perform thorough lubrication system overhauls, cleaning and flushing lubrication lines, replacing worn seals, and replenishing lubricants with high-quality robotic-grade lubricants. Regular preventative maintenance lubrication services are also offered to prevent future wear and tear.

* **Bearing Replacement and Gearbox Rebuilding:** Worn or damaged bearings and gearboxes are meticulously rebuilt or replaced. Bearing replacement is performed in cleanroom environments to prevent contamination, and gearbox rebuilding involves inspecting and replacing worn gears, seals, and bearings, ensuring smooth and efficient power transmission.

* **Structural Repair and Refurbishment:** For minor structural damage or wear, we offer structural repair services, including welding, grinding, and reinforcement. For more extensive structural damage, component replacement or full chassis refurbishment may be necessary.

**Electrical System Repair:**

* **Component-Level Electronics Repair and Replacement:** Our electrical engineers are skilled in component-level diagnostics and repair of electronic circuit boards. We can replace faulty transistors, integrated circuits, capacitors, resistors, and other electronic components, often saving clients the cost of replacing entire circuit boards.

* **Wiring Harness Repair and Replacement with High-Grade Robotic Cables:** Damaged or worn wiring harnesses are meticulously repaired or replaced using high-grade robotic cables that are designed to withstand the rigors of robotic motion and industrial environments. We ensure that all wiring connections are properly crimped, soldered, and insulated for reliable performance.

* **Motor Rewinding and Replacement Services:** For motor failures, we offer both motor rewinding services for repairable motors and motor replacement services for severely damaged or irreparable motors. We use high-quality motor windings and bearings during rewinding and source OEM or equivalent replacement motors.

* **Power Supply Servicing and Component Replacement:** Power supply malfunctions are a common cause of electrical system failures. We offer comprehensive power supply servicing, including component-level repair and replacement of faulty capacitors, regulators, transistors, and transformers.

* **Control System Troubleshooting and Repair:** Our technicians are proficient in diagnosing and repairing complex robotic control systems, including PLC systems, motion controllers, and embedded control boards. We use advanced diagnostic tools and software to identify and resolve control system issues.

**Software and AI System Repair:**

* **Software Patching and Updates for Bug Fixes and Security Enhancements:** Software glitches and security vulnerabilities are addressed through software patching and updates. We ensure that Mech’s software is up-to-date with the latest patches and security updates, protecting it from known vulnerabilities and improving its stability.

* **AI Model Retraining and Recalibration for Performance Optimization:** AI model performance can degrade over time due to data drift or changing operational environments. We offer AI model retraining and recalibration services, using updated datasets and advanced training techniques to restore and enhance the AI models’ performance.

* **Robotic Task Reprogramming and Optimization:** If Mech’s tasks need to be modified or optimized, our software engineers can reprogram its task sequences, motion paths, and control algorithms. We work with clients to understand their evolving operational needs and customize Mech’s software to meet those requirements.

* **Cybersecurity Hardening and Security Protocol Implementation:** Cybersecurity is a paramount concern for cloud-connected robots like Mech. We implement robust cybersecurity hardening measures, including firewall configuration, intrusion detection systems, and secure communication protocols, to protect the robot from cyber threats.

* **Data Recovery and System Restoration from Backups:** In cases of data corruption or system crashes, we perform data recovery and system restoration from backups, minimizing data loss and downtime. We also assist clients in implementing robust data backup and recovery procedures.

**Sensor System Repair:**

* **Sensor Recalibration and Alignment for Optimal Accuracy:** Sensor calibration drifts can lead to inaccurate readings and degraded robot performance. We perform precision sensor recalibration, using specialized calibration equipment and procedures to restore sensor accuracy to factory specifications. Optical sensor alignment is meticulously performed to ensure proper sensor positioning and focus.

* **Sensor Component Replacement with Factory-Certified Sensors:** Faulty sensors are replaced with factory-certified replacement sensors, ensuring compatibility and maintaining sensor performance. We handle sensitive sensor components with care in controlled environments to prevent damage.

* **Lens Cleaning and Optical System Maintenance for Camera Sensors:** Dust, debris, and contaminants on camera lenses can significantly degrade image quality. We perform thorough lens cleaning and optical system maintenance using specialized cleaning solutions and microfiber cloths, ensuring clear and optimal vision for Mech.

* **Signal Processing Unit Maintenance and Firmware Updates:** The signal processing units that convert raw sensor data into usable information are maintained and updated with the latest firmware to ensure optimal signal processing performance and accuracy.

* **Advanced Optical Alignment and Boresight Correction:** For multi-camera systems or sensors requiring precise alignment, we perform advanced optical alignment and boresight correction procedures to ensure accurate spatial registration and coordinated sensor data.

**Preventative Maintenance Programs:**

Beyond reactive repair services, Fix4Bot.com strongly emphasizes preventative maintenance as the cornerstone of long-term robot reliability and operational efficiency. We offer comprehensive preventative maintenance programs tailored to the specific needs and operational demands of Dexterity’s Mech and other advanced industrial robots.

* **Regular Scheduled Inspections and Performance Checkups:** Our preventative maintenance programs include regular scheduled inspections and performance checkups, conducted by our expert technicians. These inspections cover all critical systems – mechanical, electrical, software, and sensor – and identify potential issues before they escalate into major failures.

* **Routine Lubrication and Component Wear Monitoring:** Routine lubrication services are performed to ensure proper lubrication of mechanical components, minimizing friction and wear. Component wear monitoring programs track the wear and tear of critical components, allowing for proactive replacement before failure.

* **Software and Firmware Updates and Security Patching:** Preventative maintenance includes regular software and firmware updates to address bug fixes, security vulnerabilities, and performance enhancements. Security patching is performed promptly to protect against emerging cyber threats.

* **Sensor Calibration and Performance Verification:** Sensor calibration and performance verification are performed at scheduled intervals to ensure continued sensor accuracy and reliability.

* **Predictive Maintenance using Sensor Data and Advanced Analytics:** For clients seeking the highest level of preventative maintenance, we offer predictive maintenance programs that leverage sensor data and advanced analytics. By continuously monitoring sensor data and analyzing trends, we can predict potential component failures before they occur, allowing for proactive maintenance scheduling and minimizing unscheduled downtime.

* **Customized Maintenance Schedules and Plans:** We understand that every operational environment is unique. Fix4Bot.com works closely with each client to develop customized maintenance schedules and plans that are tailored to their specific robot usage patterns, environmental conditions, and operational requirements.

### Beyond Repair: Fix4Bot.com as Your Long-term Robotics Partner

Fix4Bot.com is not just a repair service; we are your long-term partner in ensuring the continued success and revolutionary impact of your investment in industrial robotics. We understand that the true value of robots like Mech is realized not just in their initial deployment but in their sustained operational excellence over their entire lifecycle. By partnering with Fix4Bot.com, you gain access to a comprehensive ecosystem of support and expertise designed to maximize robot uptime, minimize downtime, and optimize robot performance.

Our commitment to preventative maintenance is a testament to our long-term perspective. We believe that proactive maintenance is far more cost-effective and beneficial than reactive repair. Preventative maintenance not only minimizes the risk of unexpected breakdowns and costly downtime but also extends the lifespan of your robots, protects your investment, and ensures consistent and reliable performance.

Fix4Bot.com offers flexible and customizable service agreements to meet the diverse needs of our clients. From basic preventative maintenance plans to comprehensive service agreements that include on-site support, rapid response repair, and predictive maintenance programs, we have a solution to fit every budget and operational requirement. Our 24/7 support services ensure that expert assistance is always available when you need it most, minimizing disruption to your operations and maximizing robot uptime.

By choosing Fix4Bot.com, you are choosing more than just a repair service; you are choosing a partner dedicated to the long-term success of your industrial robotics initiatives. We are committed to providing the expertise, technology, and support necessary to keep your robots running at peak performance, enabling you to fully realize the transformative potential of industrial automation and maintain your competitive edge in the rapidly evolving landscape of modern industry. Let Fix4Bot.com be the guardian of your robotic revolution, ensuring that the promise of super-humanoid robotics is not just realized but sustained for years to come.

**Conclusion:**

Dexterity’s Mech represents a monumental leap in industrial automation, a true super-humanoid robot capable of revolutionizing enterprise operations. However, to fully harness and sustain this revolution, expert, specialized repair and maintenance are not just recommended – they are essential. Fix4Bot.com stands at the ready, uniquely equipped to be that expert partner. With our advanced diagnostic capabilities, precision repair methodologies, proactive preventative maintenance programs, and team of dedicated robotics specialists, Fix4Bot.com ensures that robots like Mech not only operate flawlessly from day one but continue to do so for the long haul. We are dedicated to keeping your robots running, your operations efficient, and your business at the forefront of the industrial revolution. Contact Fix4Bot.com today and let us be your trusted partner in navigating the exciting future of industrial robotics. Ensure your revolution keeps rolling – choose Fix4Bot.com.

source

0:39 My old supervisor would have a heart attack if he seen me stacking boxes with gaps like that