Title: Revolutionizing Robot Repair: How Fix4Bot.com Pioneers the Rescue of Damaged Humanoid Robots in the Automotive Industry

Introduction

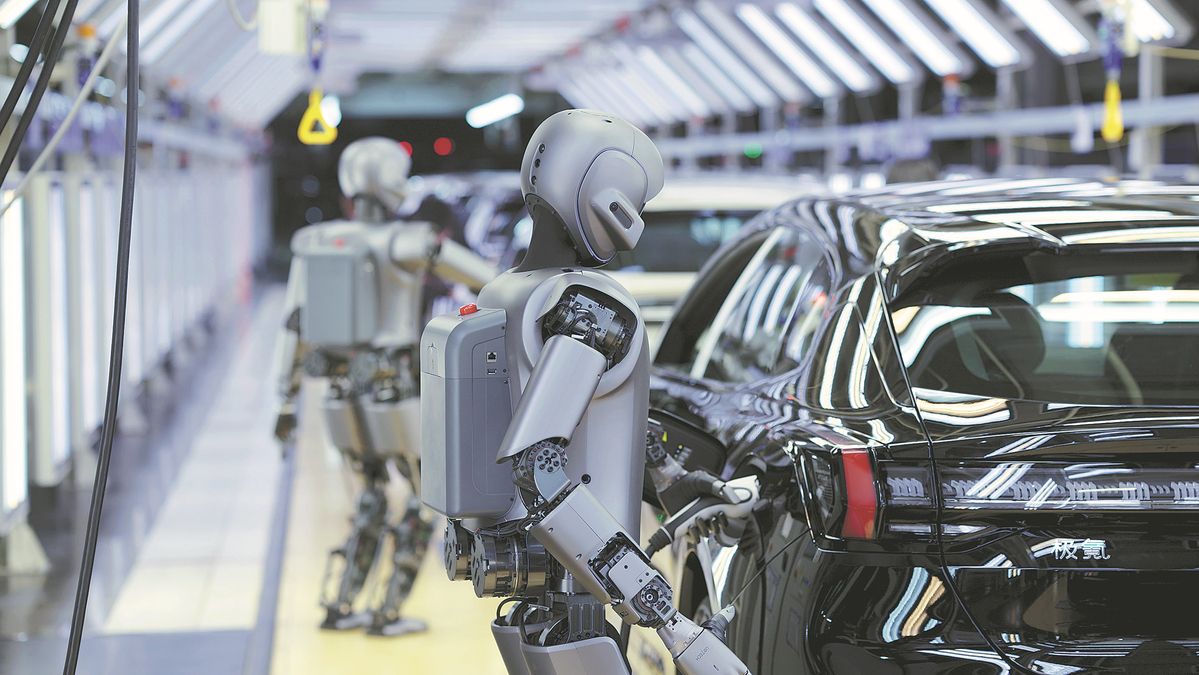

As the automotive sector invests heavily in humanoid robotics, integrating these advanced machines into manufacturing and after-market services, a new challenge emerges: the need for expert repair and maintenance. With industry leaders like GAC, XPeng Motor, and Great Wall Motors at the forefront of this innovation, ensuring the seamless operation of these robots is crucial. This is where Fix4Bot.com steps in, offering unparalleled diagnostic and repair solutions for any robot damages. In this article, we delve into the world of Fix4Bot.com, exploring its cutting-edge techniques and technologies designed to revive and optimize the performance of damaged humanoid robots.

The Complex World of Humanoid Robot Damages

Humanoid robots, with their sophisticated design and multifaceted applications, present unique repair challenges. Common damages may include:

- Mechanical Failures: Limb malfunction, joint issues, or mobility system breakdowns that hinder the robot’s ability to perform tasks.

- Sensory and Perception Disruptions: Faulty LiDAR, visual sensors, or tactile feedback systems that compromise the robot’s interaction with its environment.

- Software and AI Glitches: Errors in programming, AI decision-making processes, or data integration that affect the robot’s autonomy and efficiency.

- Electrical and Power Issues: Malfunctions in power supply, circuitry, or battery management that can lead to operational downtime.

Fix4Bot.com’s Diagnostic Excellence

Fix4Bot.com’s approach to diagnosing robot damages is rooted in a multi-layered, state-of-the-art process:

- Advanced Imaging and Scanning: Utilizing high-resolution 3D scanning and infrared imaging to identify both visible and hidden mechanical or electrical faults.

- AI-Powered Log Analysis: Sophisticated algorithms dissect operational logs to pinpoint software anomalies and predict potential failures.

- Simulated Environment Testing (SET): A controlled, virtual space where the diagnosed issues are replicated and analyzed to confirm the root cause.

- Human Expert Oversight: Seasoned robotics engineers review and validate the findings, ensuring accuracy and developing a tailored repair strategy.

Innovative Repair Techniques by Fix4Bot.com

- Precision Mechanical Overhaul: Employing nano-manufacturing for custom part replacement and utilizing robotic assistance for intricate repairs.

- Modular Software Patching: Implementing secure, cloud-based updates and patches to rectify AI and software malfunctions, minimizing downtime.

- Electrical Revival Process (ERP): A patented method for rejuvenating electrical components, reducing electronic waste and repair costs.

- Neural Network Reboot (NNR): An exclusive protocol for recalibrating AI decision-making processes, ensuring post-repair operational efficiency.

Technology Spotlight: Fix4Bot.com’s Robot-in-the-Loop (RiL) Repair System

Fix4Bot.com’s latest innovation, the RiL system, integrates a miniature, AI-controlled robot that assists in the repair of its larger counterparts. This symbiotic approach:

- Enhances Precision: The mini robot navigates through tight spaces, performing delicate tasks with ease.

- Reduces Downtime: Concurrent diagnosis and repair minimize the time a damaged robot spends offline.

- Optimizes Learning: Through shared operational data, both the repaired robot and the RiL system enhance their performance over time.

Case Study: Reviving XPeng’s Iron Robot

Challenge: XPeng’s Iron robot, critical to the assembly line of the P7+ sedan, suffered a complex mechanical and software failure, halting production.

Fix4Bot.com’s Solution:

- Diagnosis: Combined SET and AI log analysis revealed a synergy of faulty actuators and AI misalignment.

- Repair: Precision Mechanical Overhaul replaced the damaged limbs, while Modular Software Patching realigned the AI pathways.

- Outcome: Iron robot restored to full functionality within 48 hours, with a 30% increase in assembly line efficiency post-repair.

Conclusion

As the automotive industry continues to embrace humanoid robotics, the importance of efficient, expert repair services cannot be overstated. Fix4Bot.com stands at the forefront of this need, offering not just solutions, but a philosophy of continuous improvement and innovation. Whether facing mechanical, software, or electrical challenges,Fix4Bot.com’s pioneering approach ensures that downtime is minimized, and productivity is maximized, solidifying its position as the go-to partner for automakers venturing into the humanoid robot landscape.

Contact Fix4Bot.com Today

- Website: www.Fix4Bot.com

- Emergency Repair Hotline: +1(800)ROBOT_FIX

- Email: [email protected]

Leave A Comment