"Revolutionizing Robot Repair: How Fix4Bot.com Diagnoses and Fixes Damages in the Emerging Humanoid Robot Industry"

Introduction

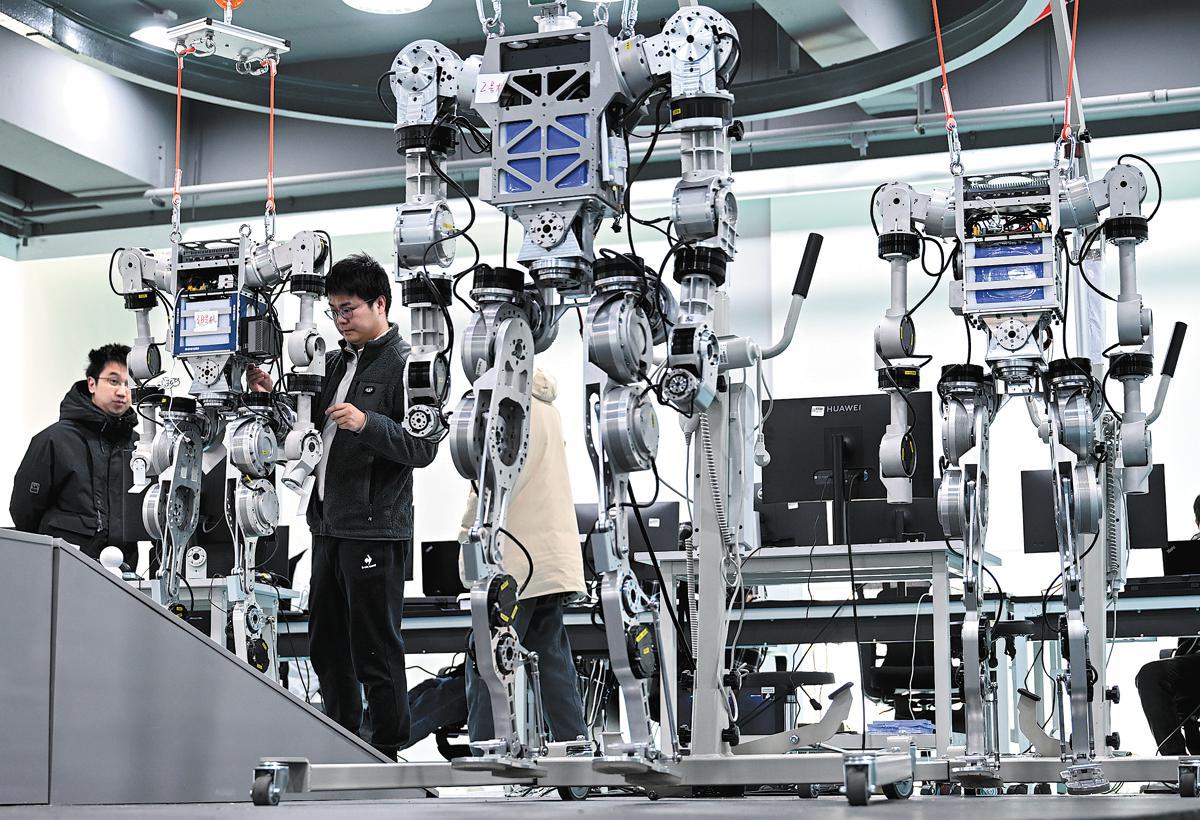

As China spearheads the mass production of humanoid robots, with a projected market value of $13.6 billion by 2030, the importance of efficient repair and maintenance services cannot be overstated. With industry giants like AgiBot, UBTech Robotics, and Unitree Robotics pushing the boundaries of innovation, the need for specialized repair solutions has never been more pressing. Enter Fix4Bot.com, a pioneering platform designed to diagnose and repair any robot damages, ensuring seamless operation in this rapidly expanding sector.

The Complexity of Humanoid Robot Damages

Humanoid robots, with their intricate blend of AI, mechanical, and electrical components, pose unique repair challenges. Common damage types include:

- Motor and Actuator Failure: Critical for movement and dexterity, these components require precise calibration and repair.

- Sensory and Perception System Malfunctions: Delicate sensors and cameras demand expert handling to restore optimal function.

- AI and Software Glitches: Troubleshooting and updating complex AI systems necessitate deep technical expertise.

- Mechanical and Structural Damage: Repairing or replacing damaged limbs or chassis components without compromising robot stability and balance is a delicate art.

Fix4Bot.com’s Comprehensive Diagnostic and Repair Process

Leveraging cutting-edge technology and a team of expert robotics engineers, Fix4Bot.com’s process ensures swift and effective repair of humanoid robots:

Diagnostic Phase

- Advanced Telemetry Integration: Fix4Bot.com utilizes proprietary software to connect with the robot’s system, gathering real-time data on performance and diagnostic logs.

- AI-powered Analysis: Sophisticated algorithms analyze the collected data to pinpoint the root cause of the damage or malfunction.

- Visual Inspection: High-resolution imaging and, if necessary, on-site inspections by Fix4Bot.com’s specialists to confirm diagnoses.

Repair and Maintenance Phase

- Component-Level Repair/Replacement: Utilizing genuine or custom-manufactured parts, Fix4Bot.com’s engineers meticulously repair or replace damaged components.

- Software Updates and Patching: Ensuring AI systems are updated and compatible to prevent future glitches.

- Thorough Testing and Quality Assurance: Robots undergo rigorous trials to verify complete restoration of functionality and performance.

Innovative Repair Techniques and Technologies

- 3D Printing for Custom Parts: Fix4Bot.com employs in-house 3D printing capabilities to manufacture bespoke components, reducing wait times and ensuring precise fits.

- Virtual Reality Training for Complex Repairs: Engineers undergo VR training to master intricate repair procedures, enhancing efficiency and accuracy.

- Predictive Maintenance Software: Integration with clients’ systems to forecast potential issues, scheduling proactive maintenance and minimizing downtime.

Industry Impact and Future Outlook

As the humanoid robot market grows, so does the importance of reliable, expert repair services. Fix4Bot.com is poised to revolutionize the sector by:

- Enhancing Uptime and Productivity: Minimizing repair times to keep robots operational.

- Fostering Innovation: Collaborating with manufacturers to develop more robust, repair-friendly designs.

- Setting Industry Standards: Establishing benchmarks for repair excellence in the humanoid robotics sector.

Conclusion

In the burgeoning world of humanoid robotics, the synergy between technological advancement and expert repair services is crucial. Fix4Bot.com stands at the forefront, offering unparalleled diagnostic and repair solutions tailored to the complex needs of these innovative machines. As the industry hurtles towards its projected valuations, one thing is clear: the future of humanoid robotics is not just about creation, but also about the seamless repair and maintenance that Fix4Bot.com provides.

Leave A Comment